【2021 Solutions】 Exclusive Innovative AI Algorithm Miniaturization Patent: Mantuo Technology Assists in Bringing Large-Scale AI to the Cloud

With the Internet of Things, the demand for AI algorithms is becoming increasingly massive and complex. The use of Edge AI, which can effectively reduce costs, enhance security, and improve execution efficiency, will become an inevitable trend.

Founded in 2018, Mantuo Technology's DeepMentor mainly provides miniaturized AI algorithm SaaS services. It is a real solution provider on the market that can deploy AI algorithms running on cloud servers or GPU processors to the Edge Device level, maintaining an accuracy of over 99% while significantly reducing data movement and algorithm complexity. Its exclusive and innovative Miniaturized Electronic Design Automation process (MAT) can shorten time, reduce costs, and still achieve an accuracy higher than 99%, key for deploying cloud AI to Edge Devices.

Ten years of dedication, Mantuo Technology's miniaturization technology gains market attention

After more than ten years of research and development in the laboratory, the founder of Mantuo Technology, Wu Xinyi, and his team's exclusive patent of the miniaturized electronic design automation process has resulted in over 20 international A-level papers and several awards including the Best Paper Award. Mantuo Technology's technology has been recognized by the market, and in the past two years, it has won the 'Most Investment Worthy Award' at the 8th Yungu Cloud Leopard Incubation Demo Day and the 'Strongest System Innovation Award' with Chunghwa Telecom, as well as the '2021 G Camp International Link Award' and the 'YEZ International Accelerator Special Award' at the 5th 'International Innovation and Entrepreneurship Training Camp (G Camp)' organized by the Ministry of Economic Affairs in August 2021.

▲滿拓科技獲得第八屆雲谷雲豹育成總決賽「最具投資價值獎」。圖(左二)為滿拓科技創辦人吳昕益。

AI algorithms are quite large mathematical models. Mantuo Technology is focusing on future trends from the era of the Internet of Things (IOT) to the intelligent Internet of Things (AIOT). All kinds of terminal products will integrate AI to provide more powerful functions. However, many AI algorithms are relatively complex and large, which cannot be integrated into existing terminal devices. Therefore, Mantuo Technology developed an exclusive miniaturization technology (MAT) to optimize the algorithms, simplifying the complex algorithms so they can be incorporated into small embedded systems for easier interfacing with hardware equipment.

Indeed, what challenges do companies currently face when deploying Edge AI? Mantuo Technology's Marketing Director, Yang Yuming, explains that in terms of hardware computation, the cost of GPUs is high, and due to power consumption and heat generation, they are not suitable for edge computing devices. In terms of software, there is a lack of good solutions on the market, and most applications can only deploy lightweight simple AI models (tiny AI), which are easily affected by climate or external environmental changes, significantly impacting accuracy. Importantly, including major international manufacturers in their 2021 white papers, it is mentioned that accuracy can be immediately reduced by 5-15% during the compression process. Mantuo Technology offers a complete Edge AI computing solution, with its exclusive and powerful miniaturization technology, which can reduce computational and data volume by 90% while keeping accuracy within 1%, successfully deploying multiple complex professional million-parameter AI algorithms to edge devices.

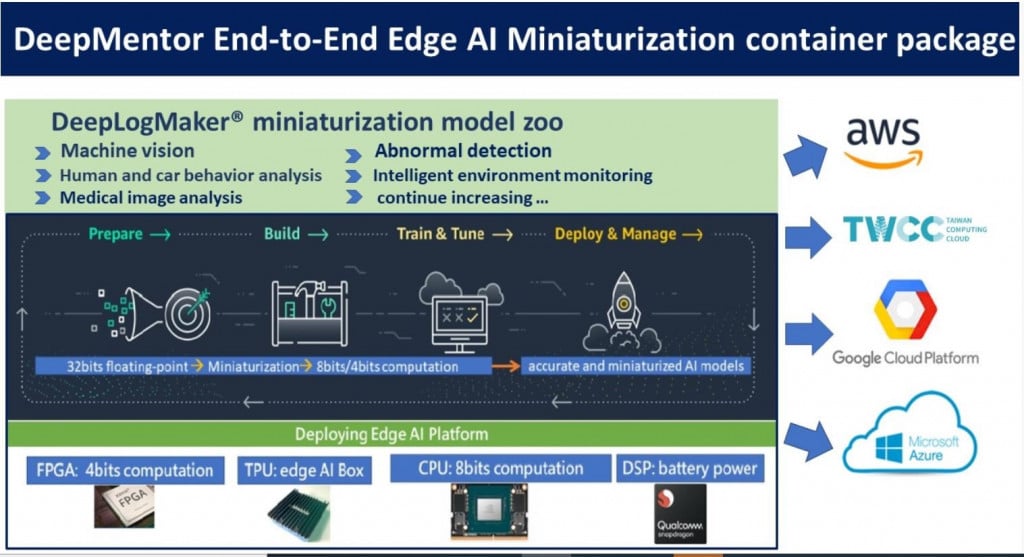

Mantuo Technology's main customers target system manufacturers and software and hardware developers who want to upgrade IoT to AIoT. Mantuo provides the DeepLogMarker software platform to help system vendors and developers quickly obtain miniaturized AI algorithms. Through simple training and deployment, they can easily convert commercial IoT devices into AIoT products.

Yang Yuming stated that the company will launch the SaaS software platform service DeepLogMarker in the fourth quarter of 2021. The first phase will offer the nine most commonly used professional miniaturized AI algorithms, such as object recognition, posture detection, facial recognition, and age and gender algorithms, allowing customers to choose as needed. Different AI functions can also be combined according to different usage requirements. The platform adopts a subscription model, providing all AI developers, like engineers, startup teams, and device manufacturers, to download and use these algorithms.

SaaS platform services - simple subscription to use AI algorithms

Specifically, customers only need to select the required algorithms on DeepLogMarker, and with a few steps, they can deploy the algorithms to the Edge AI hardware platform. Customers do not need to spend a substantial amount of资金capital and time to build an AI environment, and even beginners in AI can directly access all kinds of AI applications needed on the DeepLogMarker platform. Mantuo Technology provides professional AI models that have been miniaturized, allowing startup entrepreneurs and developers to subscribe to miniaturized AI algorithms and purchase the Edge AI box to interface with their IoT systems, thereby upgrading the IoT systems to AIoT systems.

Mantuo Technology is committed to becoming a SaaS software company in the Edge AI field. By the end of 2021, it will provide a variety of Edge AI solutions and algorithms on the online platform, hoping to build a complete DeepLogMaker Edge AI user ecosystem. Enterprises and cloud service providing platforms like Amazon AWS, Microsoft Azure, IC design companies, startups, and IoT device manufacturers can use the AI services from Mantuo Technology on the platform, to inspire various innovative applications, enhance AI value, and create business opportunities together.

▲滿拓科技建構DeepLogMaker Edge AI使用者生態圈

At the same time, strategic partners with international SaaS operations experience are also welcome to join hands with Mantuo Technology. Besides deepening the Taiwanese market, Mantuo Technology's services will also expand into East Asia and international markets such as the United States and Europe. The ultimate aim is to significantly reduce the deployment cost of Edge AI, help in the widespread application of AI at a grassroots level, and broaden the applications of Edge AI in intelligent retail, smart manufacturing, smart home appliances, smart medical, and more.

Mantuo Technology believes that now is the best time for Taiwanese manufacturers to enter the Edge AI market. Currently, major chip manufacturers such as NVIDIA, Intel, Qualcomm, NXP, and cloud leaders AWS, Google, Microsoft are all actively investing in this field. If Taiwanese manufacturers want to break into the Edge AI market, considering the strengths of Taiwan's small and medium-sized enterprises, industrial manufacturing advantages, and government resources, unique value in software and hardware integration and technology is still the best leverage. Finding the right entry point, Mantuo Technology hopes to become the key hub that connects international software giants' resources with Taiwan's hardware advantages.

Mantuo Technology's miniaturized algorithms enable Edge devices to perform more robust AI functions. With the advent of the 5G era, the various AI intelligent application scenarios that everyone is looking forward to can truly materialize. The current IoT products need to be fully upgraded. 'Solving problems through system integration is solving problems from the root.' Mantuo Technology's software and hardware integration solutions, including various AI silicon IP licensing and SaaS services, are expected to officially hit the market from the end of 2021 to early 2022, at which time the development of AI applications in Taiwan may show a different aspect.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」