【2022 Solutions】 Rebirth the music on the hard drive. Aifei Matchmaking uses AI to find the best partner for the image.

A young girl, alone in Los Angeles, USA, is looking for a dream, a dream that allows the music creator to find her soulmate again with the music she buried deep in the hard drive...

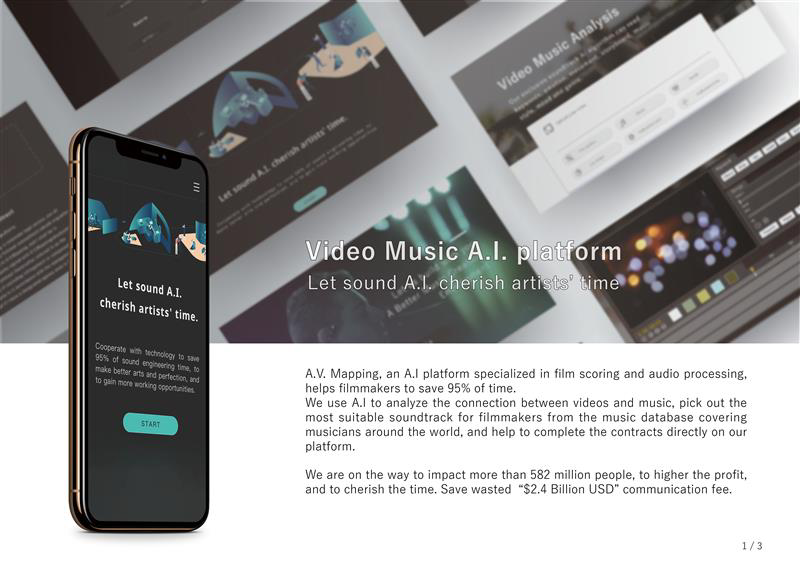

Li Zihui, the founder of iFeiMedia, has a background in science and engineering, but she has a strong gene for musicians. In order to help global musicians create music and find the "best partner" who can successfully match them, she founded iFeiMedia. Ping Company provides a one-stop AI video and music matching platform (A.V. Mapping) to help video creators quickly find copyrighted original music.

One-stop AI image music matching solution to find innovative business opportunities for music creators

Generally speaking, in the past, video creators had to work on video music, including composing lyrics, music, and finding copyrights. It usually took two weeks. Through the A.V. Mapping video and music matching platform, it can be instantly matched to a suitable video in 10 seconds. Music, musicians can also remarket their creations to gain profit sharing, creating a win-win situation. This new, decentralized operating model is also favored by the descendants of the late Taiwanese music master Li Taixiang. On the platform, you can relive a time when music creation was free to fly.

Li Zihui has practiced piano since she was a child, participated in choirs and wind bands, and composed her own music. Although she studied science and engineering in college - the Department of Surveying and Spatial Information at Cheng Kung University, she joined the imaging team to work on soundtracks from her junior year. , and went to the Applied Music Department of Nanyit University to audit. After graduating from college, Li Zihui decided to obey the voice in her heart and become a music dreamer.

▲Aifei Matching provides a one-stop AI image and music matching solution

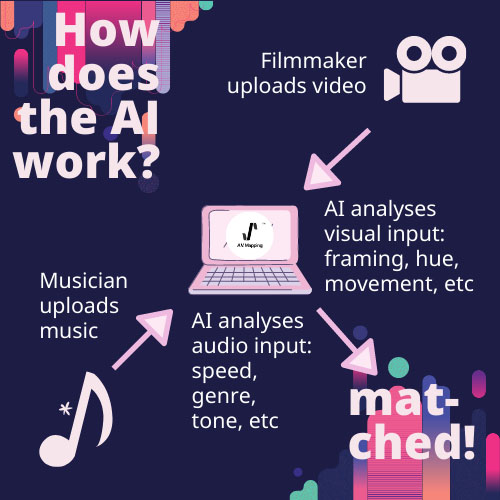

Aifei Matching provides a one-stop AI image and music matching solution, which mainly uses artificial intelligence image recognition and music analysis. Image creators can search and match suitable music by themselves on the platform, and use the system to It can shorten the duration of the soundtrack from 8 hours to a few seconds, a significant reduction of nearly 2,000 times.

Li Zihui said that in addition to creating suitable soundtracks, traditional video scoring projects also require a lot of time and cost in communication and search, including subsequent post-production processing such as arrangement and recording, and music licensing, which are even more time-consuming and labor-intensive. With the assistance of AI, creators can focus all their efforts on creation without worrying about finding suitable music or having their music copyright stolen.

Integrated virtual and real marketing, from transaction to contract signing with one click

At present, AifeiMeiping's music database has a total of 60,000 tracks in more than 60 categories, covering music from Europe, America, Asia and other parts of the world, including pop, EDM, rock, Irish music, etc. The original decentralized concept of iFlyMediaPing further protects the rights and interests of musicians. Musicians on the platform can set their own prices and track the transaction process, achieving open, transparent and decentralized features. There are currently more than 7,000 video and music creators on the platform. Music creators who successfully trade on the platform can share profits of more than 40%, up to 50%. The two parties transact and complete the contract on the platform, and the procedure is very simple.

▲A.V.Mapping has a total of 14 AI models, making it easy to find speed dating music

Li Zihui said that the AI image music matching solution has a total of 14 AI models. The method is to disassemble all elements, conduct music analysis through image recognition and text recognition, and then use machine learning algorithms to train extensively. The characteristics of images and music are listed, which can quickly match the soundtrack that suits the image situation, atmosphere, and rhythm.

In addition to online matchmaking transactions, Aifei Matchmaking also holds physical concert events, inviting music and video creators to participate. The content of the event revolves around the display of AI video soundtracks, and a video directed by the director is used on-site to allow music creators to participate. PK soundtrack; or take out a demonstration video and let AI match it. It only takes 10 seconds. The images and music matched by AI are very accurate in terms of mood and atmosphere, which amazed the participants.

Three years of research and development won the Red Dot Design Award, using technology to support the development of music and art

Aifei MatchPing spent three years of research and development, and the platform was officially launched in August 2021. In January 2022, it participated in the CES event in Las Vegas, USA, which attracted great attention from reporters present and received more than 100 awards in total. media reports, the number of uses in a month has exceeded 1,000 times, attracting 7,000 video and music creators to join the matchmaking platform. According to statistics, in the initial stage, the proportion of matchmaking transactions between the United States and Taiwan is evenly divided.

Li Zihui said that the licensing methods of traditional music are very complex, including types of works, types of copyright property rights, etc. To obtain authorization for a song, one must go through a songwriting agency, a collective management group, a production company, a record company, or even a composer. , lyricists, it is very cumbersome, and musicians may not necessarily get profit sharing. Through the AI image music matching platform, all transaction contracts are completed online, music creators can gain profits, and their creative enthusiasm is constantly stimulated.

▲Three steps to help video creators easily complete the soundtrack work

It is worth mentioning that NFT (Non-fungible token, also known as non-fungible token) is currently very popular in the art and cultural market. What is the possibility of introducing it into the field of video and music? Li Zihui said that the current transaction fees (gas fees) of Ethereum remain high, and coupled with the conclusions she obtained from attending many gatherings in Los Angeles, the acceptance of NFT is still in the process of brewing. However, Aifei Matching is still optimistic about the future of NFT. Trend, in the foreseeable future, relevant technologies will still be introduced into the A.V. Mapping platform to provide more diversified trading methods.

In order to rapidly expand overseas markets, Li Zihui continues to seek funding from international strategic investors in San Francisco. At the same time, due to the appropriate control of the epidemic in Los Angeles, the industry is gradually recovering, and Li Zihui also participates in many offline creative gatherings. Aifei Media hopes to become a bridge connecting images and music, introduce well-known user cases in the international market, and let more creators see the power of the platform.

Aifei Media Ping also frequently reports good news. After winning the DSA Digital Advertising Singularity Silver Award and the AWE Female Entrepreneurship Best Potential Award co-organized by the American Institute in Taiwan and META, the one-stop AI video and music matchmaking company founded by Li Zihui The platform (A.V. Mapping) also won the Best of the best in the Design Concept of the German Red Dot Award in 2020. We hope to continue to be based on technology and nourished by art. Support music creators to create better works.

▲Li Zihui, the founder of Aifei Matchping, has won many international awards and is a female entrepreneur with great potential

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」