【2020 Application Example】 AI Helps Establish the Best AOI Parameter Model for Passive Components, Reducing Production Costs of Over-Screened Components, Saving NT$2.5 million Annually

Traditional AOI uses limited sample images for inspection, facing the problem of high over-screening rates

In the electronic component manufacturing industry, AOI (Automated Optical Inspection) equipment is often used to measure defects in product appearance. For a long time, AOI measurement equipment has used limited sample images in image processing to compare the appearance of products from different external light sources and angles.

This comparison method can automatically screen for defects in product appearance. However, due to current technical limitations, there are often problems with light source parameter adjustment between product batches. If an inexperienced technician handles these adjustments, it will lead to a decrease in machine utilization rate and high over-screening rates.

The maturity of AI image machine learning has brought new opportunities for the AOI process

In terms of Taiwan's passive components, chip resistors and MLCC currently rank in the top two worldwide in terms of market share in 2019. In the long term, various car manufacturers have launched electric vehicles and smart vehicles, and various countries have also developed 5G-related equipment, which will further increase future shipments of passive components. Therefore, besides expanding new product lines, how to help existing products enhance their competitiveness will be the key to the industry's future international competition.

AOI inspection is one of the common stations in the passive component process, limited sample images are used in the current stage to compare the appearance. However, when switching between product batches, there are often problems with light source parameter adjustment, and the condition of these adjustments will affect the over-screening (mis-screening) of good products in each batch. In each batch of defective products in the industry, on average over-screening (mis-screening) occurs 20% of the time.

Relying on the guidance capabilities of the Southern Taiwan Industry Promotion Center, which has been deeply involved in Southern Taiwan for more than a decade, the company was matched with the AI image recognition technology unit of the Industrial Technology Research Institute (ITRI) to address the pain points of the passive component industry, reducing over-screening in the AOI process and also reduce errors caused by manual adjustment.

Using image recognition technology to reduce the occurrence of AOI over-screening

The technical unit of the ITRI that participated this time used image recognition technology to develop AOI technology for passive component processes in the establishment of AI modules.

In the development process, the company in this case first provided product appearance images and corresponding adjustment parameters, and then used the adjustment logic of current production line personnel to construct a product data set and further establish an AI model. When planning the production line test, the first priority is image recognition rate. Image detection and tag search are combined with comparison by an AI module to output AOI adjustment parameters for reference by online personnel.

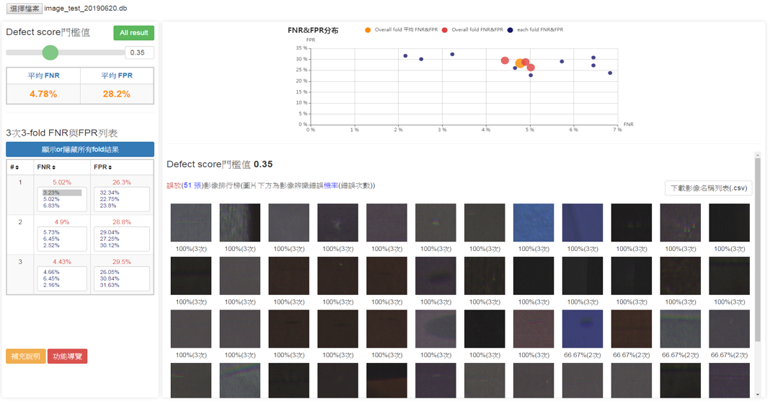

▲Image analysis diagram

In the future, we also hope to use the help of machine learning to complete the AI learning curve for machine parameter adjustment, further reduce the over-screening rate of product appearance defect detection, simultaneously solve the gap in on-site professional and technical talent, and increase product yield.

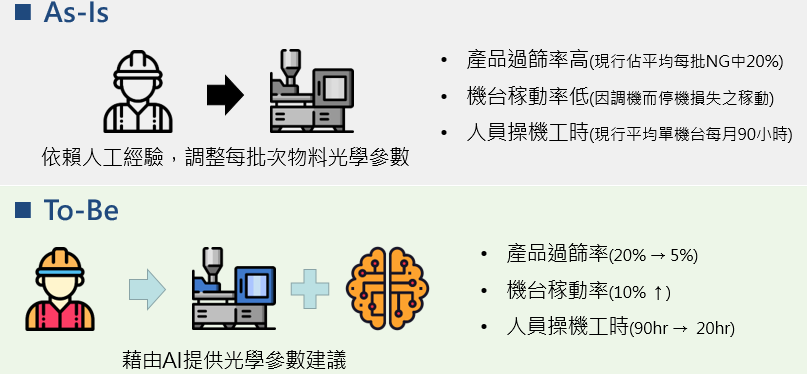

▲ Scenarios before and after implementing machine learning

Implementing AI applications in processes to lay the foundation for developing unmanned factories

In the future, we hope the guidance of AI HUB will accelerate the application of advanced process technology and establish AI indicators for each station of the passive component process, which will help domestic production of high quality passive component products and increase product yields and prices. It will use innovative thinking to increase the added value of the industry and continue to lead the passive component industry forward.