Zcon Telehealth uses AI facial recognition to detect physiological data so that people can know everything about their own health

On a weekend morning, Grandma Li, who lives in Taipei, was happily having a video call with her little granddaughter in Tainan through the screen of an AI health management robot Then at 900 am, the foreign domestic helper's mobile app displayed a health management reminder sent by the robot, notifying that Grandma Li needed her daily physiological data measurement Grandma Li faces the camera on the robotrsquos screen, and the screen displays Grandma Li's blood pressure, blood oxygen, heart rate, heart rate variability, and stress index The robot detected that grandma's blood pressure was a little high, and a picture of blood pressure medicines immediately popped up on the screen to help the foreign domestic helper quickly find the medicines, making Grandma Li feel more at ease when taking medicine This AI telehealth care application is not futuristic, but rather the AI-enhanced comprehensive telehealth care solution of Zcon Telehealth, which has been established for 10 years, providing thoughtful companionship for the elderly through AI It can be used for non-contact physiological data measurement in the post-pandemic era, significantly cutting the labor cost of care in half

Bobby Pan, the founder and president of Zcon Telehealth, which has accumulated abundant technical capabilities in the telecommunications and banking industries over 20 years, observed that the demand for telehealth care is an inevitable business opportunity, and decided to establish Zcon Telehealth in 2013 He worked hard with the core AI technology team to develop a comprehensive telehealth care solution Four years ago, he set the goal to develop an AI-based telehealth care platform, and returned to school to study in a doctoral program, focusing on the research of contactless detection of physiological data using AI facial recognition technology He successfully obtained an invention patent 2 years later Zcon Telehealth is the third company in the world after an Israeli company and Taiwan's National Chiao Tung University to provide technological and service innovations for AI facial recognition to detect physiological data, and successfully incorporated it into the company's telehealth care management platform

As Taiwan becomes an aging society, demand on elderly care will increase and become more diverse In addition, the increase in demand on physiological data measurement due to COVID-19, coupled with the shortage of manpower in care institutions, has highlighted the importance of telehealth care solutions The market demand for telehealth care can be divided into three main service targets home, social residence, and institutions Telehealth care can provide real-time physiological data detection, and the data can be uploaded to the cloud for storage, effectively solving the problem of insufficient caretaking manpower

Seeing that the demand for telehealth care is irreversible at home and in care institutions, Bobbdy Pan observed that telehealth care should have five major elements, namely precision care, precision medicine, precision diet, precision health supplement, and AI companion robot He looks forward to the five major elements effectively connecting Zcon Telehealth's healthcare products, and providing more considerate telehealth care services for senior citizens or institutions To this end, Zcon Telehealth uses AI technology to strengthen comprehensive telehealth care solutions The company's products are integrated into four major areas, including telehealth care management platform, tele-psychological consultation platform, AI health management robot, and physiological data detection technology using AI facial recognition

AI facial recognition technology contactless physiological measurement obtains data within 30 seconds, saving 12 of the labor cost of care

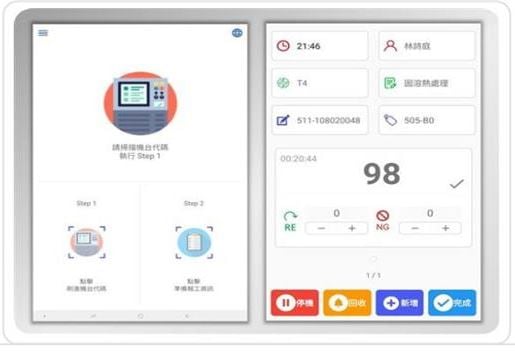

The telehealth care management platform is an important core care platform of Zcon Telehealth It effectively integrates the exclusive measuring equipment provided by the company to daycare center, such as blood pressure monitors, forehead thermometers, and i-GlucoPal - needle-free blood glucose detection By downloading the smart care app of Zcon Telehealth, it can help long-term care institutions collect physiological data records of the elderly, and store the data in the cloud via Bluetooth transmission, allowing institutions to quickly obtain health data reports of the elderly Elderly people can also download the app, and use their own account and password to accurately measure and record their personal physiological data At the same time, family members can also use the account and password of their elders in institutions to keep an eye on the elder's health status and past measurement records The company is currently cooperating with 8 daycare centers affiliated to the Taiwan Rehabilitation Technological Association through the telehealth care management platform, which can significantly save 12 of the care labor cost, and has successfully provided 2,000 elderly people with general home care

Regarding the tele-psychological counseling platform, Bobby Pan said that the company began to promote it in 2018, but online psychological counseling was not popular at that time Counseling centers only needed to use LINE or video platforms to provide services It was not until the COVID-19 pandemic in the past two years that caused people to go out less, which caused psychological counseling centers to lose a large number of customers Therefore, tele-psychological counseling platforms have become an important service channel for counseling centers to develop their customer base The tele-psychological counseling platform is provided to counseling centers in the form of an app Its functions include Google Meet video, online appointment, cash flow from payments, case management, account management, and emergency notification Counseling centers obtain a private account through Zcon Telehealth, and will be able to independently monitor the database management status of the counseling center, such as psychologist schedule management Zcon Telehealth thoughtfully provides the UberPsycho app service to clients After downloading the app, customers can locate and instantly match with the nearest counseling center and matching location to complete the search for a counseling center Customers can subsequently make an online video call or go to the counseling center to meet their counseling needs, breaking the limitations of space and meeting customers' needs for real-time consultation or spiritual companionship when they are emotional, truly achieving "Anywhere, Anytime, On-Demand Service" The product is an online psychological counseling platform that has been reviewed and approved by the Health Bureau and is compliant with regulations Counseling centers only need to apply online to start online counseling services, and do not need to worry about system setup At present, the tele-psychological counseling platform has successfully cooperated with 18 counseling offices in Taiwan

Recognizing that AI companionship and housekeeping are important trends in telehealth care, Zcon Telehealth launched Taiwan's original AI health management robot, integrating hardware manufacturers with health management software services provided by Zcon Telehealth The service functions of the AI health management robot include the physiological measurement of Zcon Telehealth's Smart Care app combined with its own measuring equipment blood pressure meter, forehead thermometer, blood glucose meter, cloud storage of physiological measurement data and abnormal data notification, remote video monitoring, caregiver work reminders, medication reminders, and physiological data functions based on AI facial recognition The AI health management robot is mainly targeted at families with foreign caregivers Employers can set work item and time reminders on the Zcon Telehealth Smart Care app, such as accompanying elders for a walk, elders taking medicine, or taking photos while the elders are in bed The robot's screen or voice playback reminds foreign caregivers of work items when caring for the elderly When the foreign caregivers finish their work, they must tap the complete button on the robot's screen to indicate that the task was completed The AI health management robot can help employers effectively remotely track whether foreign caregivers have completed daily elder care tasks as scheduled In addition, employers can have video conversations with their elders through the app and the screen of the AI health management robot The screen can also display pictures of medicine to reduce the risk of elderly people taking the wrong medicine

Bobby Pan said that "zero contact" has become an important hygiene behavior in the post-pandemic era Combined with telehealth care, Zcon Telehealth has launched AI facial recognition technology to detect physiological data, which is different from typical wearable devices in the market, such as smart watches or bracelets that use photoplethysmography PPG for contact-based physiological detection Zcon Telehealth uses remote photoplethysmography RPPG for facial detection This method extracts signals from the tiny periodic color changes in light reflected from the skin caused by heartbeat RPPG can be roughly described as a modified version of reflective PPG, in which ambient light replaces LED and a camera lens replaces the photoelectric detector Physiological data detection technology based on AI facial recognition uses contactless measurement to detect changes in facial blood flow through images This technology can simultaneously integrate measurement of blood pressure, blood oxygen, heart rate, heart rate variability HRV, and stress index Users only need to face a regular webcam or mobile phone lens for 5 seconds, and reference data of the five physiological indicators can be detected and displayed within 30 seconds The data can be viewed in Android, iOS, or web version This product can achieve convenient self-health management and measurement functions for those who frequently travel abroad, workers such as security guards, service providers such as taxi drivers, or migrant workers, replacing the inconvenience of carrying various physiological measurement equipment in the past

Zcon Telehealth is the third company in the world to provide physiological data detection technology based on AI facial recognition The company has successfully applied for an invention patent due to the innovation of this technology and services AI facial recognition health management has successfully cooperated with the health management center of a hospital in Kaohsiung, and provides the center's members who download the app with self-health measurement services In addition to health examination centers, the AI facial recognition health management service also cooperates with domestic TV manufacturers to develop customized Android TV apps and integrate them into Internet-connected TVs to provide health measurement detection services

Physiological data detection technology based on AI facial recognition can quickly measure and provide physiological data - Demonstration by Bobby Pan, founder and president of Zcon Telehealth

Psychological consultation AI brainwave detection equipment to understand customers' mental health status in advance

In terms of tele-psychological counseling platform services, Zcon Telehealth not only assisted counseling centers with developing new remote customer service channels during the pandemic, but also uses the UberPsycho app to quickly help customers match with psychological counseling centers that suit them It has also successfully provided value-added services that combine psychological counseling at counseling centers with AI brainwave equipment for brain health assessment through clinical verification It also obtained brain assessment and test reports, and then guided customers to appropriate psychologists for counseling

"More than 23 million people in Taiwan receive psychological counseling services every year, and about 110 of them, or more than 230,000 people, need further psychiatric treatment" In addition, the psychologists have different clinical experience and judgment Bobby Pan pointed out that if psychological counseling can be combined with AI brainwave equipment for brain health assessment, and it can provide customers with the early prevention mechanisms of "mental health examination" and "psychological counseling" He believes that the company can quickly grasp the customer's mental state and prevent them from doing something they will regret With the support of the AI HUB project of the Industrial Development Bureau, Ministry of Economic Affairs, Zcon Telehealth cooperated with 5 counseling centers in field verification, providing the counseling centers with AI brain health assessment equipment The customer test report includes simple mental assessment, heart rhythm assessment, autonomic nervous system assessment, behavioral response assessment, brain health assessment, neurological response assessment, and brain emotion assessment

In terms of breakthroughs in AI technology, Zcon Telehealth connects devices through a brain-computer interface for brain health assessment indicators, transmits physiological data, and uses a long-short-term memory model and convolutional neural network to analyze neural indicators It automatically generates a cognitive function assessment report through cloud services as the quantitative result of mental health examination This value-added service of the verified mental health examination solution has been actively expanded to all counseling centers in Taiwan through cooperating counseling centers In the future, the company will continue to cooperate with medical institutions and health examination centers to expand its business

Psychological consultation AI brainwave detection equipment to determine mental health status in advance

In terms of business model, physiological data detection technology based on AI facial recognition uses a non-binding payment mechanism Individuals or companies will receive AI blood oxygen detection cards provided by Zcon Telehealth, and scan the QRCode on the card using their mobile phones for unlimited self-health measurements within one month They only need to pay NT300 per month, which is quite affordable In addition, the fee for the telehealth care management platform is also very affordable at only NT100 for each account For the tele-psychological counseling platform, Zcon Telehealth signs annual contracts and bills customers on monthly basis The AI health management robot is provided for customers to buy out

Looking towards the international market while based in Taiwan, developing diverse telehealth services

From the perspective of Zcon Telehealth, how to successfully develop products, market them, and expand business opportunities has been a challenge since the company was founded Among them, the company's development of physiological data detection technology based on AI facial recognition was the most challenging Bobby Pan said that since there is no precedent in the industry, the only way was to go back to school to study Fortunately, he was admitted in a doctoral program two years ago and read countless foreign journals, which he then integrated into product design and development It took 2 years of hard work to achieve this result Zcon Telehealth is not only passionate about the development of AI-enhanced telehealth care services, but also believes that AI-based contactless physiological health measurement and data can provide people and care institutions with a more affordable, convenient, fast, and considerate health measurement option in the post-pandemic era

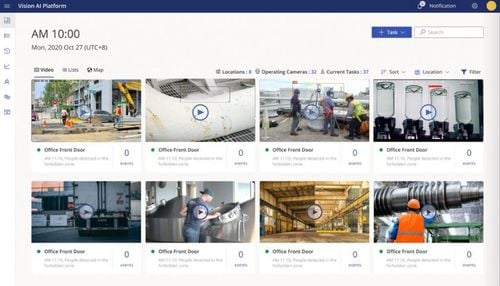

In terms of business strategy, Bobby Pan hopes that recent promotion of the physiological data detection technology based on AI facial recognition will continue to increase market share and create cooperation opportunities with channels To this end, the SDK Software Development Kit developed by Zcon Telehealth allows any application owner to embed it into their solution, and can use the SDK to directly detect physiological data on Android or iOS devices It is also applicable to mobile phones, tablets, smart TVs, or smart health mirrors In the future, Zcon Telehealth will primarily target large-scale health companies for cooperation, and looks forward to finding more potential partners with the assistance of the Institute for Information Technology III

In the past two years, Zcon Telehealth has actively expanded into the field of AI healthcare and maintained its leadership in AI facial recognition technology Facing the fiercely competitive AI healthcare industry, Bobby Pan said that Zcon Telehealth must plan ahead and will first provide physiological data detection technology based on AI facial recognition to charity and religious groups free of charge, in order to increase product visibility in the short-term In the mid-term, Zcon Telehealth will partner with large health companies, such as health examination centers, and utilize the big data collected through the cooperation to plan customized health products and services For long-term development, Zcon Telehealth plans to set up a branch in Texas, USA by the end of this year and establish local distribution channels It will actively expand business to emerging potential markets, such as Vietnam, the Middle East, and South America

You can know what people look like but not what's going on inside Zcon Telehealth breaks through the traditional approach and uses AI facial recognition technology to detect multiple physiological data in 30 seconds, gaining insight into an individualrsquos current health condition, so that it can not only know what people look like, but also what's going on inside Bobby Pan said that it took years of hard work to complete the development of physiological data detection technology based on AI facial recognition Zcon Telehealth is looking towards international markets while it is based in Taiwan, and will develop diverse telehealth services

Bobby Pan, founder and president of Zcon Telehealth