【2020 Application Example】 "AI Embroidery Pattern Recognition System" effectively improves pattern recognition efficiency by 50 times!

Influenced by fast fashion, the OEM model of large variety in small quantities has become the development trend of the textile industry

"Fast fashion" features fast, cheap and fashionable. Taiwan has been affected by the rise of fast fashion in recent years. The OEM model of "wide variety in small quantities" has become the development trend of the textile industry. The primary goal of the textile industry is to understand how to receive purchase orders under this fashion trend.

Customer inquiries for new patterns can only be searched manually, which is time-consuming and inefficient.

Chairman Chen of a leading domestic textile company took over as the chairman of the "Taiwan Underwear Innovation Alliance" in 2018. He has engaged in the design and development of embroidery patterns for more than 40 years and has developed more than 30,000 embroidery patterns. Whenever international corporate customers request a price quotation for a new embroidery pattern, it takes about 2.5 hours of "manual search" to find 1 to 2 similar patterns for quotation. Therefore, the main bottleneck is how to quickly identify "embroidery patterns."

Cleaning and organizing raw data takes a lot of time

To build an AI model that can quickly identify and find similar embroidery patterns, a large amount of embroidery pattern data needs to be used for learning during the model development stage. Each embroidery pattern requires pre-processing, including watermark removal, border removal, and pattern standardization. It will take one full-time employee six months to complete image pre-processing. The textile company provided a total of 30,125 embroidery patterns for AI machine learning and identification. The data were annotated and divided into seven categories of patterns.

Improved AI accuracy through pattern recognition and learning

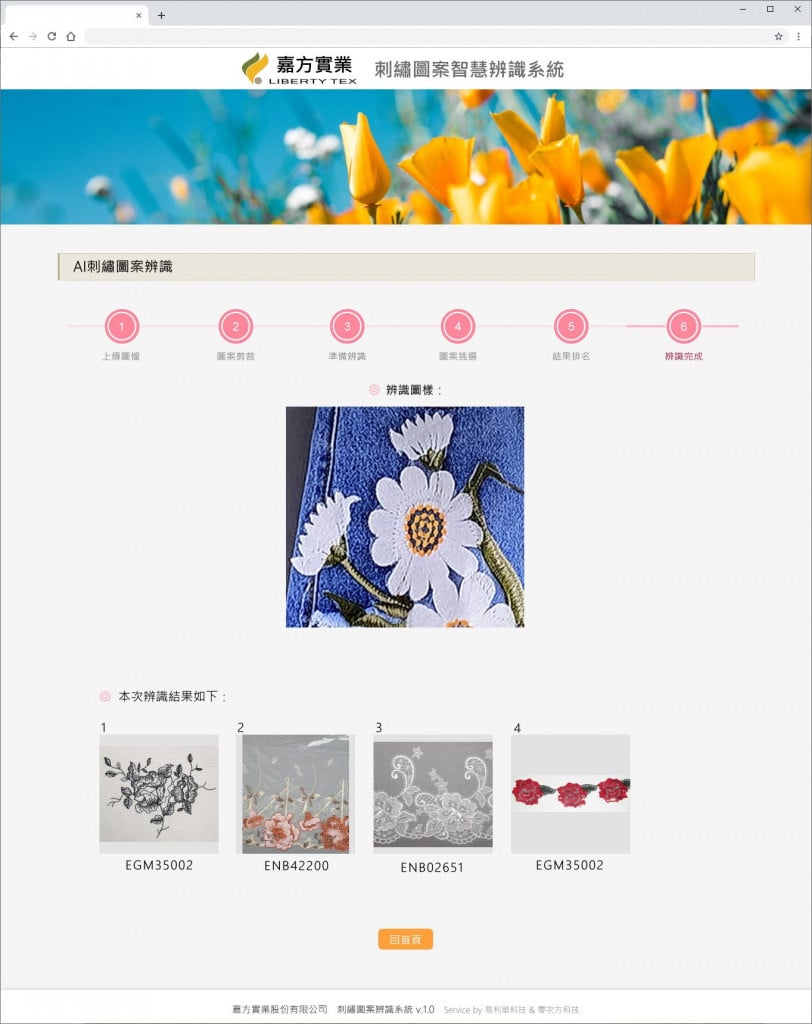

When a customer requests a price quotation for a new embroidery pattern, sales personnel can first upload the image to the system and check which important elements need to be identified, such as: style, shape, category, pattern, and size, and then select several satisfactory options from the many options recommended by AI. The results are sorted and stored according to "satisfaction," and recognition results and the user's score are stored in a cloud database. By recording the standards and key points of AI pattern recognition training, we can verify whether any images were left out and the reason why certain images were not selected.

In addition to finding similar patterns, another challenge of "embroidery pattern recognition" is "psychological level" cognition of human beings, including "different users' preferences" and "users' consideration of customers' preferences," both of which will affect selection results. The user's selection results, "satisfaction" scores, and "the operator's psychological level" preferences make the AI model more accurate.

The development of an "AI pattern recognition system" to assist manual work allows similar patterns and solutions to be found within 1 minute, significantly improving work efficiency by 50% and improving order-taking efficiency to cater to the fast fashion industry.

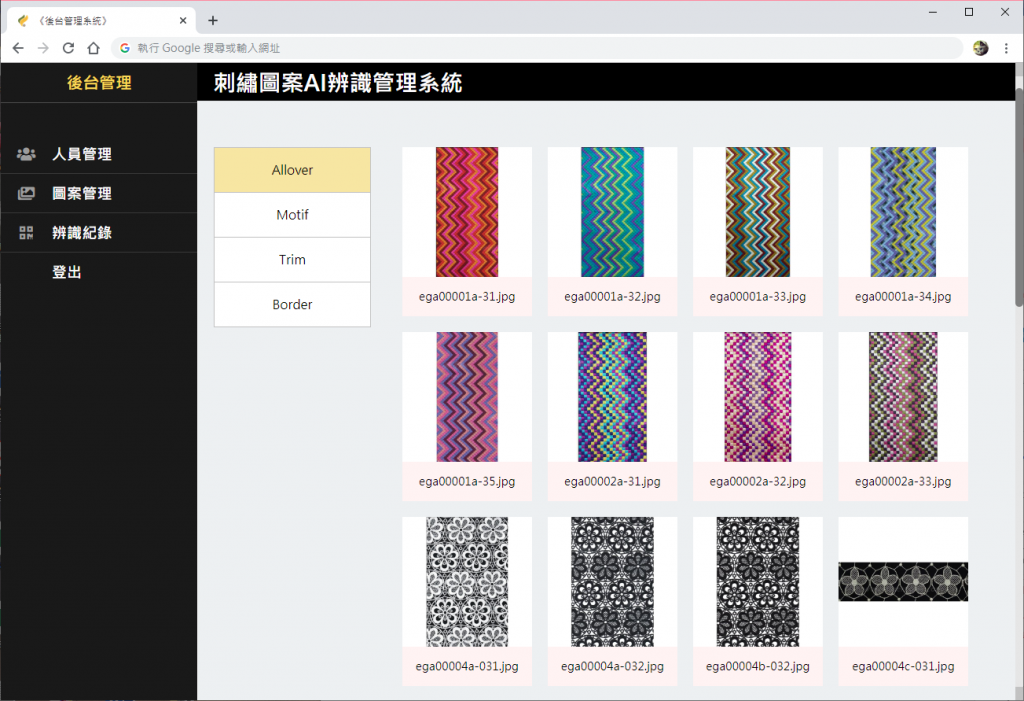

▲Schematic diagram of embroidery pattern AI recognition management system

▲Schematic diagram of embroidery pattern AI recognition results

Establish the "Taiwan Textile Industry AI Pattern Recognition Service Center and Platform"

This "AI Embroidery Pattern Recognition System" project will work with more textile companies and resources in the future to establish a business model for the "Taiwan Textile Industry AI Pattern Recognition Service." Introducing this AI recognition system to the upstream and downstream of the industry chain will jointly improve the technological level, operational efficiency and international competitiveness of Taiwan's textile industry!