【2020 Application Example】 AI Cold Chain Transportation Breakage Warning System - Reducing the Proportion of Temperature Loss in Chilled Products and Enhancing Product Value!

Direct delivery of fresh vegetables and fruits from Shangqing, temperature control is key

Preserving the freshness of vegetables and fruits is one of the crucial aspects of the agricultural production and sales model. Enhancing the efficiency of fresh preservation and integrating cold chain transportation management are critical issues that agriculture businesses need to address. In Taiwan, agricultural lands are small and scattered; hence, entering the cold chain transportation immediately after harvesting and strict temperature control are essential for maintaining freshness.

Instances of temperature loss and cold chain transportation breakdowns are increasingly evident

The vegetables supplied by the vendor have been highly favored in the market recently, achieving record sales in chain supermarkets and making efforts to enter higher-end consumer markets. Recent acquisitions of fresh vegetable supply channels from McDonald's, Costco, and Taiwan Plastic's Steakhouse highlight the need for previously unnoticed issues in the company's own cold chain transportation system to be addressed and enhanced for storage and transportation efficacy.

Incorporating more IoT and AI architecture and functionalities

This 'AI Cold Chain Transportation Breakage Warning System' uses IoT and AI technology to help vegetable suppliers analyze their cold chain systems, particularly focusing on personnel management and resource wastage or damage to fresh products due to improper decisions by personnel.

By using the Beacon system, AI analyzes the movement paths of chilled goods within and outside the company, personnel needs management, and data analytics. It considers neural network learning elements like 'movement paths of chilled goods after storage', 'personnel involvement', and 'product quality at sale'. By learning through AI, the system solves and enhances 'internal personnel merchandise quality', 'external chilled vehicle service quality', and establishes 'product quality monitoring and warning' functionalities, achieving comprehensive beneficial effects!

IoT sensor data collection

Based on different needs of each refrigerated space of the vegetable supplier, temperature or humidity abnormality alarms are set. When an anomaly occurs, the authorized person's app notifies with a push notification and informs the SOP. For more critical issues, an SMS push service is available to notify surveillance personnel not equipped with the app to handle urgent procedures at once, minimizing loss.

▲Temperature and humidity sensors placed in refrigerated spaces

▲Refrigerated storage monitoring system APP screen

為確保生鮮蔬果運送過程中溫度未被破壞,也確保進出冷藏室時間差以保證產品品質,並確保商品於正確時間送達正確地點,「Beacon溫度、濕度監測系統」能依據現場條件自動調整Beacon訊號發送間隔時間(自5秒鐘至5分鐘),且電力能維持至少1年,而溫度、濕度蒐集設備則可應用到非AI功能之冷鏈追蹤記錄系統,並藉手機APP便能獨立偵測、蒐集並進行運輸過程冷鏈溫濕度追蹤,著實大大提升運送過程控管的便利性!

▲Beacon溫度偵測設備安裝1

▲Beacon溫度偵測設備安裝2

運送行為資料蒐集

此次合作的蔬果供應商其冷鏈監測項目,包含:位於集貨廠內之真空高速降溫冷卻機(可將貨品快速降溫至0℃~3℃)及12個冷藏庫、理貨場的堆高機工作環境溫度大約20℃~25℃,停留時間不超過20分鐘,運送車輛上車前車輛裝載空間溫度約0℃等,這些條件理論上都可符合整體冷鏈需求,但實際運作上卻出現相當多狀況。

此次合作除落實冷鏈運輸及管理細節,同時確保產品運送品質,萬一在運送過程品質發生問題,也能在第一時間透過系統得知貨品狀況,若「貨品已經損壞」則立即退回不要出貨給客戶,若是「成為高風險貨品」(可能保鮮期變短,則立即做成便當或特價促銷處理),若是「安全抵達」則可以追蹤整體運輸溫度變化及批次貨品品質確認,同時對於送錯目的地貨品之狀況也能夠立即追蹤處理,避免交易糾紛,有效降低冷藏產品的失溫耗損比例!

▲Beacon訊號偵測設備安裝

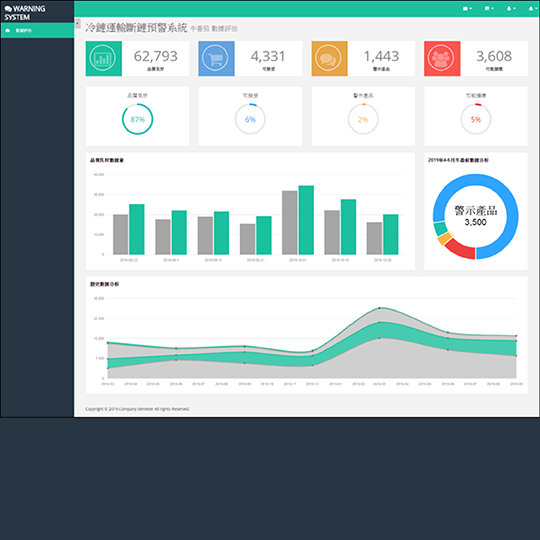

AI建模進行冷鏈風險分析評估

導入AI建模分析後之成果可有效監視每一批冷鏈商品運送過程之品質,同時提供合作企業最真實的冷鏈品質回饋,管理階層對於每日大量之儲存、運輸貨品一目瞭然,同時,系統在人員還沒得知產品因為溫度變化而導致品質改變前,便可立即主動示警,有效減少商品損壞可能。

▲系統管理後台介面

導入AI及物聯網能量後,大幅提升90%以上附加價值

一、冷藏商品失溫損壞比例降低62%

以蔬果供應商108年3至6月之牛番茄產品損壞率21%做為產品損壞之依據,本計畫系統建立後,冷藏商品因溫度變化品質受損之數量,較安裝AI冷鏈監測系統後之108年7至10月牛番茄商品損傷比例可降低至87%。

二、提升產品價值30%

以蔬果供應商108年3-6月之牛番茄產品銷售額12,464,175元做為提升產品價值之依據,以物聯網加值AI功能後之冷鏈管理系統價值,較只使用溫度記錄裝置管理系統之價值,108年7至10月牛番茄產品銷售額提升率可達30%。

蔬果供應商導入AI冷鏈運輸斷鏈預警系統,展開智慧運輸新篇章

蔬果供應商導入AI冷鏈運輸斷鏈預警系統,可降低冷藏商品失溫損壞比例並提升產品價值,更可利用自動預警過期機制,智慧化記錄空間溫度變化並精準監測物品存放位置。未來在冷鏈營運上,將佈建全新冷鏈服務通路,並多方應用冷鏈品質追蹤管理技術,建立智慧運輸的新篇章!

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」