【2021 Application Example】 Preventing Problems Before They Arise: Leadtek Research Develops AI Technology for Early Detection of Heart Failure Symptoms

With the increase in the elderly population, the incidence of various chronic diseases is rising daily. Among these, heart failure is not only a silent killer; it has a very long disease course with a high recurrence rate, leading to increased burden on healthcare personnel. However, by using medically certified electrocardiography acoustics devices, coupled with AI predictive assessment of heart failure risk and remote care systems, diagnosis can be aided significantly, helping doctors make accurate diagnoses for subsequent patient medical care or referrals.

Heart failure has a lengthy course and medical expenditure is five times that of diabetes

If you find yourself short of breath even with minimal movement, or if you wake up from sleep needing to sit up to feel comfortable, or if you have symptoms such as swollen lower limbs, anxiety, restlessness, fatigue, or a loss of appetite, be cautious! These could be signs of heart failure.

According to statistics, there are about 60 million people with heart failure worldwide, with 5 million new cases every year. In China, nearly 290 million people suffer from cardiovascular diseases, accounting for the second leading cause of death among urban residents; around 12 million of these are heart failure patients, accounting for over 59% of cardiac-related deaths. The disease course of heart failure is exceptionally long, and both its recurrence and rehospitalization rates are exceedingly high, resulting in medical costs that are twice that of hypertension and five times those of diabetes.

According to U.S. research statistics, the 30-day mortality rates for patients with myocardial infarction and heart failure are respectively 16.6% and 11.1%, and the rehospitalization rates within 30 days are 19.9% and 24.4%. The symptoms of heart failure, because they are similar to those of other diseases such as chronic obstructive pulmonary disease and asthma, have an 18.5% misdiagnosis rate, which poses a challenging problem for healthcare institutions.

Leadtek, a major graphics card manufacturer, has been investing in the medical and healthcare sector since 2000. Following two heart attacks in 2011 and 2015 experienced by Chairman Lu Kunshan, Leadtek has focused on health big data, independently developing AI technology for heart failure recognition. This AI application reads patients' electrocardiograms and phonocardiograms to perform anomaly detection and model prediction of heart failure risk, enabling early detection of disease symptoms.

Leadtek independently developed heart failure AI recognition technology to predict medical history and risk

Leadtek's independently developed heart failure AI recognition technology has the following three judgment functions:

1. Prediction of heart failure history: Classifies electrocardiogram and phonocardiogram data into 'with hospitalization history of heart failure' and 'no history of heart failure'.

2. Risk prediction of heart failure: Provides a predictive risk value of heart failure occurrence based on the electrocardiogram and phonocardiogram data.

3. Prediction of heart failure recurrence risk: For patients with heart failure, it reads their phonocardiogram and electrocardiogram data, assessing the risk prediction of heart failure recurrence.

Leadtek states that the application of heart failure AI recognition technology can assist doctors in making more efficient and accurate diagnoses, facilitating subsequent medical treatment or referrals for patients. As an instance, in studies of heart failure patients discharged from Taipei Veterans General Hospital, using the EMAT (Electromechanical Activation Time index) and SDI (Systolic Dysfunction Index) calculated by the synchronized electrocardiography-acoustic device as treatment guidelines resulted in a higher survival rate compared to those treated based on traditional symptoms. This research has also been published in the authoritative international cardiology journal JACC, receiving recognition in the international market.

▲System manufacturers can apply heart failure AI recognition technology for other value-added applications

Leadtek states that cooperating system manufacturers can choose to build their own heart failure AI risk prediction engine, uploading their system's electrocardiogram and phonocardiogram data to Leadtek's heart failure AI risk prediction engine, which then returns risk prediction values for integration by system manufacturers / cooperating manufacturers as a value-added application input.

Not just for clinical use, the heart failure AI risk prediction engine can also be extended for use at home or in the workplace

Additionally, this system can be extended to other applications, including:

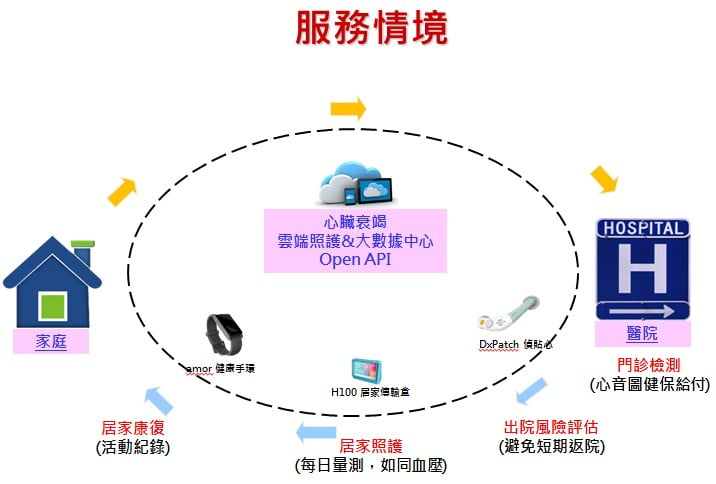

One, hospital outpatient screening: Doctors can use the electrocardiogram and phonocardiogram recorder along with the heart failure AI risk prediction model to conduct a 10-second rapid test in outpatient and emergency departments to assess a patient's cardiac history and heart failure risk. Two, discharge risk assessment: Doctors can use the electrocardiogram and phonocardiogram recorder along with the heart failure AI risk prediction model to assess the heart failure risk during a patient's hospital stay. The test data can serve as a pre-discharge risk assessment and prognostic indicator.

Three, continuous home care: Patients can use the electrocardiogram and phonocardiogram recorder, wearable electrocardiogram recorder, and transmit through a home transmission box (gateway) to measure electrocardiogram and phonocardiogram signals at home and upload them to the amor health cloud platform for heart failure AI risk prediction analysis. Patients can manage their health autonomously via an APP, reviewing historical physiological trends; disease management nurses can manage member health through the health management backend Web.

Four, home rehabilitation training: Patients can wear a health bracelet to monitor activity, fatigue, circulation, and sleep, autonomously managing their health through the mobile APP and observing the risk of heart failure, engaging in exercise and rehabilitation training to aid in swift recovery.

▲The heart failure AI recognition technology system can also be extended to employee home care applications.

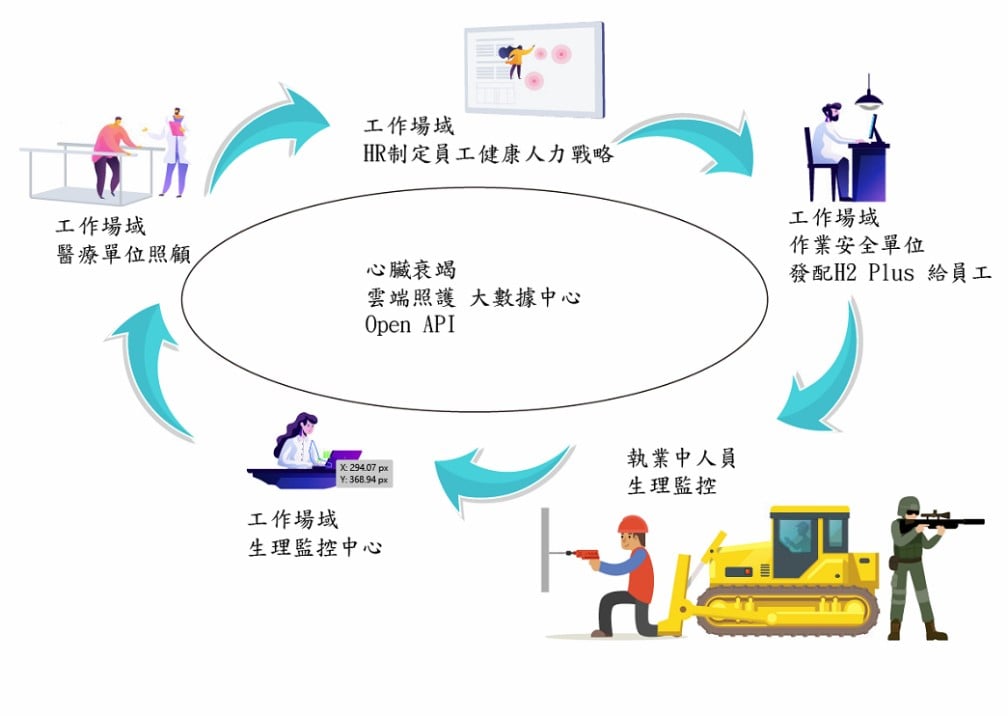

Additionally, in factories or offices, this system can also achieve employee health management goals, with applications including:

One, workplace safety units: Provide employees with wearable electrocardiogram recorders before they start work duties.

Two, physiological monitoring for business executors: While executing business duties or training, employees wear wearable electrocardiogram recorders for fatigue warnings, signaling whether physiological conditions allow continued execution of tasks. Task segments can use data transmission boxes or apps to upload physiological monitoring information to the health management platform, assessing the heart failure risk for operations staff, with test data serving as an indicator for enterprise resource human units and public safety.

Three, workplace physiological monitoring center care: The workplace physiological monitoring center can inspect and record employees' historicalphysiological trends through the health cloud platform.

Four, workplace nursing units: Nursing units receiving instructions from the physiological monitoring center can provide health management advice based on employees' physiological trends; nursing centers can manage employee health through the health management backend Web. Five, employees can wear health bracelets to monitor activity, fatigue, circulation, and sleep, autonomously managing their health and observing the risk of heart failure through the mobile APP, engaging in exercise and rehabilitation training to aid in rapid recovery.

▲Workplace application of heart failure cloud care and big data center diagram

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」