【2021 Solutions】 Specializing in the smart medical market, Kaiyuan Intelligent Manufacturing and hundreds of doctors "struggle for feelings"

The rapid advancement of artificial intelligence (AI) technology and the new coronavirus pneumonia (Covid-19) epidemic have catalyzed the vigorous development of smart medical care. Kaiyuan Intelligent Manufacturing Company, which is committed to the research and development of Open AI, focuses on the development of the smart medical market. The company spent two years I visited doctors one by one over the course of a year, "struggled emotionally" with hundreds of doctors, and compiled a "Smart Medical Question Bank", which is like an AI martial arts guide in the medical field. All medical and engineering-related questions can be found in this book answer. Establishing a common language with doctors can help break into the development of the medical field.

According to the definition of the World Health Organization (WHO), smart medicine is an extension of digital medicine. It is the application of information and communication (ICT) technology in the medical and health fields. Its scope includes: medical health information, personal medicine, telemedicine and Care, mobile medicine, wearable devices, etc.

The growth potential of the global SaMD market is amazing, and major technology companies are rushing in

Among them, the SaMD (Software as a Medical Device) market is expected to grow at a compound annual growth rate of 69.30% during the forecast period from 2019 to 2026. Due to the endless market potential, world-class industrial and information communication companies are actively rushing to enter. However, the barriers to entry in the medical industry are not low. How to talk to doctors has become the first problem.

Open AI Fab, founded in May 2019, is a consistent winner of the AI GO "Industrial Problem-Producing, Innovative Problem-Solving" and AI HUB AI+ New Talent Selection Competitions in the AI Program of the Industrial Bureau of the Ministry of Economic Affairs. Huang Mingshi, founder and CEO of Kaiyuan Intelligent Manufacturing, said that the company continues to accumulate experience through projects and competitions. In the field of smart medical care, "doctors" are important and key figures. Kaiyuan Intelligent Manufacturing not only recruits emergency room doctors to serve as medical directors , as a bridge of communication with the medical community, the company team visited hundreds of doctors in two years to understand the needs and enter the huge market of smart medical care.

"Doctors are very smart and their time is precious. Answering his questions quickly and accurately in a short period of time and building mutual trust are important keys to whether the two parties can have substantial cooperation." Huang Mingshi further emphasized that doctors also have a strong interest in AI. There is unlimited imagination. However, AI technology that uses deep learning requires doctors’ annotation. If doctors cannot assist in annotation, AI will be of no use. The first step in establishing communication with doctors is to establish appropriate expectations for AI.

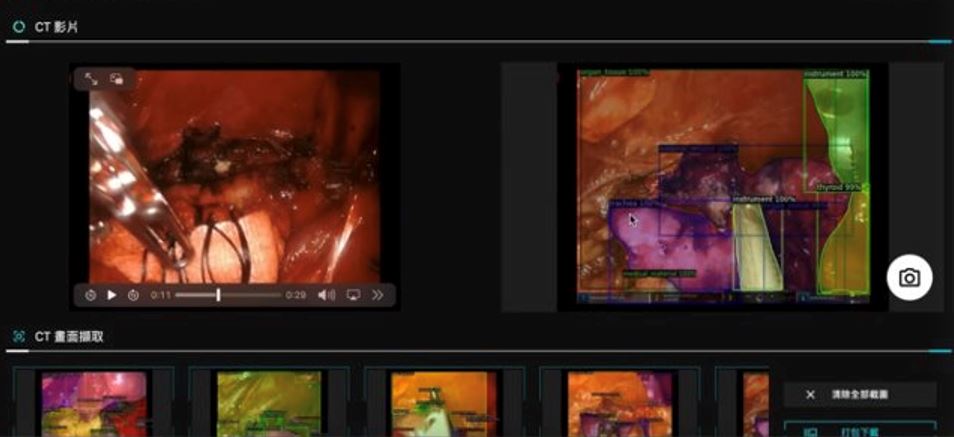

Through cooperation with Northern Medical Center and Southern Medical Center, Kaiyuan Intelligent Manufacturing has two relatively mature medical AI services: "Da Vinci Surgery Organ Identification Solution" and "Heart Failure and Structural Abnormality Solution". The Da Vinci surgical organ recognition solution uploads Da Vinci surgical video files. Doctors can choose the images they want to recognize, and the AI model will identify different organs, nerves, blood vessels, etc. from all the images together.

▲Da Vinci image recognition AI can be applied to obstetrics and gynecology or otolaryngology.

Da Vinci image recognition AI was originally used in obstetrics and gynecology. The open source intelligent manufacturing team spent more than half a year adjusting the model of Da Vinci organ image recognition in obstetrics and gynecology around the clock, and then found UNET AI from Open Source (open source code) Model, a large number of model optimizations have been carried out. At this stage, four of the eight human organs can achieve an accuracy of 85%.

For this year’s AI GO competition, Kaiyuan Intelligent Manufacturing also assisted the Department of Otolaryngology at the Central Medical Center to establish Da Vinci organ image recognition. In just one month, from the initial discussion, data collection, data annotation, and AI model creation , and finally obtained empirical results, gradually shortening the learning curve through the process of customizing AI.

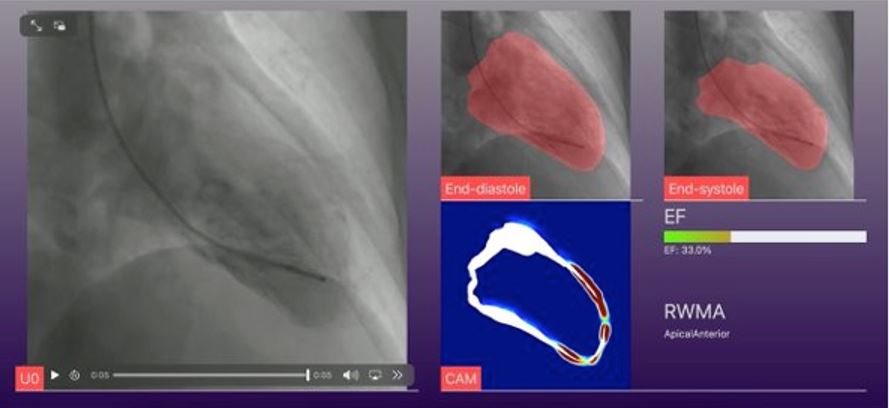

The time taken by AI to calculate cardiac ejection fraction is shortened from 20 minutes to "seconds"

In addition, solutions for heart failure and structural abnormalities will become the first step in the productization of open source intelligent manufacturing AI. Huang Mingshi said that when the cardiac surgery department of Southern Medical Center performs cardiac catheterization on patients, doctors also need to take left ventricular photography. After injecting the contrast agent into the patient, the doctor can draw the outline of the heart through the diastolic and systolic images of the heart at different times. , and calculate the cardiac ejection fraction. There are two shortcomings in the traditional method. First, drawing and labeling require a lot of time for doctors. Second, doctors use manual drawing to calculate the cardiac ejection fraction. The standards are inconsistent, resulting in the lack of objective standards. .

The solution for heart failure and structural abnormalities through deep automatic learning technology not only shortens the time for doctors to draw the outline of the heart and calculate the cardiac ejection fraction from 20 minutes to "seconds", it can also help doctors analyze the ventricles. abnormal conditions, and establish an early warning platform for heart failure and structural abnormalities.

▲Heart failure and structural abnormality solutions will become the first step in the productization of open source intelligent manufacturing AI

In the process of communicating with doctors, Huang Mingshi found that the biggest difficulty for doctors is to obtain and label cases after de-identification, which takes a lot of time. Taking the left ventricular photographic film as an example, a patient In a two-minute video, there are 30 photos that need to be annotated in one second. The number of photos that need to be annotated in two minutes is as high as 3,600 photos. It takes a lot of time for just one patient, not to mention that a doctor may have dozens of patients. bit, it takes more time.

In addition to collecting questions and answers from interviews with hundreds of doctors and establishing a question bank, Kaiyuan Intelligent Manufacturing also trains engineers and data scientists to learn data annotation by doctors. After repeated confirmation with doctors, the main data annotation work at this stage can be left to engineers. Practical solution to doctors’ problems. In smart medical care, due to different departments, racial differences, different conditions of each patient, and different hospital needs, it is difficult to produce a universal and standardized AI model in the short term, and customization is the best way. Kaiyuan Intelligent Manufacturing adopts the Open AI method to shorten part of the development time and focuses on technological breakthroughs in customized AI model construction. The developed AI modules can extend their application fields, which is also one of the company's competitive advantages.

Medical devices are independent from pharmaceutical affairs laws and obtaining medical device software certification is the top priority

In order to develop Taiwan's smart medical industry, the Food and Drug Administration (TFDA) of the Ministry of Health and Welfare passed the "Medical Device Management Act" in December 2019, which will separate the management of medical devices from the "Pharmaceutical Affairs Act" and will be implemented in May 2021. It will come into effect on January 1st. Medical device software (SaMD) requires product developers to obtain license approval from local competent authorities before it can be sold in local medical channels. Therefore, Kaiyuan Intelligent Manufacturing will prioritize obtaining SaMD licenses in the United States and Taiwan.

Huang Mingshi pointed out that Kaiyuan Intelligent Manufacturing just received angel round financing in 2020, and it is expected to complete the Pre-A round of financing by the end of March 2022, which will be used as funds for the next year and a half. At the same time, we also plan to obtain the second-level medical device software certification from the Food and Drug Administration of the Ministry of Health and Welfare within 2 years, and complete the smart medical AI product development plan. ) strives to introduce practical applications and make smart medical care practical and popular.

▲Huang Mingshi, founder and CEO of Kaiyuan Intelligent Manufacturing

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」