【2022 Solutions】 Watertight smart industrial safety inspection Linker Vision’s image analysis AI platform sets a new record of inspection time reduced from 100 minutes to 3 seconds

With the rise of smart manufacturing, there is a demand for industrial safety inspections in high-risk industries such as chemical, energy, and electrical industries. Take pipeline inspection in the chemical industry as an example. It relies heavily on manual regular inspection and monitoring, and lacks intelligent monitoring by a professional AI team. This is not only time-consuming and labor-intensive, but may also cause accidental risks to employees in various industrial safety environments. The image analysis AI platform developed by Xinyun Linke not only improves employee personal safety and reduces risk factors, but also significantly reduces the time for human visual inspection of pipeline abnormalities from an average of 100 minutes to 3 seconds.

Paul Shieh, founder and chairman of Linker Vision Co., Ltd. (Linker Vision), said, "The overall technological development and progress in the United States comes from entrepreneurship. Linker Vision's original intention to start a business in Taiwan has been I hope that through my past experience in entrepreneurship in the United States, I can introduce the American entrepreneurial spirit and culture to Taiwan's budding entrepreneurial fertile ground and truly implement it. "American entrepreneurial culture encourages employees to value ownership and emphasizes that employees regard themselves as owners of the company. Be a part of the company, with a work attitude and spirit that would be better than mine. The company's achievements are your own achievements, breaking the original employer-employee relationship. The company will reward outstanding employees with stocks, share the glory together, and establish a partnership with employees. Partnership. On the other hand, Taiwan still has room for efforts in entrepreneurial culture and management, and it retains the traditional thinking of employers and employees. It is expected that Xinyun Linke's establishment of American entrepreneurial culture and values in Taiwan will serve as a starting point to drive more domestic new companies to follow suit, and then Only by upgrading the business constitution of new software AI entrepreneurs can they break out of the cocoon and go global.

Facing the market, most international players focus on developing AI models and algorithms. They are less willing to invest in data-centered (Data-Centric) AI services. They think that processing large amounts of 2D or 3D data is quite time-consuming. It’s also energy-consuming. Seeing the gap in AI technology and encouraged by Microsoft, Xinyunlinke decided to fully invest in Data-Centric's AI technology layout and deep roots many years ago, and specialize in technical energy in data processing, filtering and accuracy. Therefore, Become an important partnership with Microsoft for AI technology supply. In addition, due to the gap in industrial demand, domestic large factories, whose strength is chemical manufacturing, still rely heavily on manpower for inspection of pipelines in the factory, which is time-consuming and labor-intensive. However, in order to cater to the AI industry, the owner reorganized the IT department originally engaged in database management and control into an AI team. However, due to the owner's lack of professional experience in AI software technology, AI models and related domain know-how, the owner introduced AI implementation. Industrial safety monitoring in the chemical industry is even more challenging.

The world's first AI automatic labeling technology surpasses manual labeling and can visually identify objects with an accuracy of over 95%

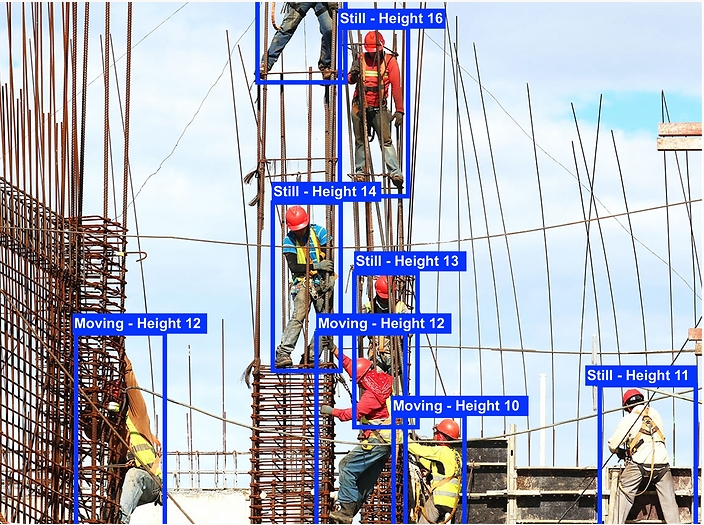

In terms of AI technology power, Xinyunlinke has launched the world's first dual-core innovative technology of automatic labeling (Auto-labeling) and automatic machine learning to create an efficient and stable image analysis AI platform to provide customers with the best Advanced and complete AI solutions. In terms of automatic annotation, this AI technology can overcome the most difficult challenge in deep learning, which is to provide customers with the highest quality training data. Taking self-driving cars as an example, how to enable one self-driving car to effectively identify another car is the importance of labeling. In the past labeling methods, we first needed to collect digital images of millions of vehicles, roads, signs, and pedestrians, and spent a lot of manpower. Manually labeling one image at a time was time-consuming, labor-intensive, high in labor cost, and inefficient. Through automatic labeling AI technology, combined with automatic machine learning to automatically label digital images, AI can exclude human error labeling and then throw the correct data into the vehicle's brain for vehicle identification. Compared with manual labeling accuracy of only 60%, the accuracy of automatically labeling and identifying objects with AI can be as high as over 95%. It can also reduce manual labeling time by more than 80% and save at least 80% of labor costs.

▲AI automatically marks AI behavior recognition for high-altitude operations

In the automatic machine learning part, Xinyunlinke established an AI visual model with continuous learning capabilities to adapt to data changes. By optimizing the overall development process, from AI data ingestion and filtering (Data Selection) to AI labeling (AI Labeling) , model training and verification, deployment and monitoring, so that AI computer vision can continue to learn more quickly and easily. Automatic machine learning can currently be applied to different business cases such as object identification and counting, personnel entry and exit security detection, product defect detection, people flow identification, product shortages on shelves, etc.

Looking at domestic companies such as TSMC, Formosa Plastics and Hon Hai towards intelligent AI management and purchasing a large number of cameras to meet the image recognition needs of industrial safety surveillance, coupled with the introduction caused by the unfamiliarity of existing customer organizations with AI applications Thresholds and preliminary preparations for image recognition include complicated workflows such as data screening and annotation. To this end, Xinyunlinke has been committed to accelerating the development of AI computer vision applications in recent years, providing client-to-end services, and can flexibly deploy according to customer needs. Complete automated AI solution services in the cloud, on-premises, or cloud + on-premises. Xie Yuanbao said that the AI automation technology process provides data selection (Data Selection) AI technology through domain-type pictures given by customers, helping customers automatically filter out precise (such as 10,000 transactions) from a large amount of data (such as 1 million transactions). Data, and by using the AI algorithm technology of Auto-Labeling to replace manual labeling, it can effectively save customers a lot of labor costs and achieve efficient data labeling processing. In addition, the AI technology of automated machine learning can help clients customize automatic AI model training or repeated training when the factory environment changes, providing more accurate AI models and allowing customers to operate autonomously. Through the above-mentioned key features and advantages of the automated AI technology provided by Xinyunlinke, we believe that it can definitely meet the needs of customers for an automated end-to-end AI independent learning platform, and at the same time, it can significantly save customers the cost of AI team establishment.

In terms of technological competitiveness, in addition to providing the chemical industry with AI image analysis applications in smart industrial safety, Xie Yuanbao said that Xinyunlinke can also extend the process application of automatic annotation and automated machine learning to different industrial landing services, such as Various fields such as self-driving cars, smart warehousing self-propelled robots and self-driving buses in future smart cities are all in line with the spirit of automated mobility of Mobility as a Service. We look forward to the role played by Xinyunlinke. The process of image annotation in different industries accelerates the efficiency of developing image recognition services in different fields. We believe that by providing client-to-end AI solutions and a complete set of automated AI image analysis pre-operation processes from Data Selection AI technology, Auto-Labeling AI technology, and automated machine learning AI technology, we can greatly satisfy our customers. The demand for AI autonomous learning platform.

Image analysis AI platform sets a new record for smart industrial safety inspections from 100 minutes to 3 seconds

Seeing the high demand for industrial safety supervision in high-risk industries such as the chemical industry in recent years, Xinyunlinke launched the "Vision AI Platform", which uses AI image recognition technology. Its main functions include real-time AI streaming It has four major functions: detection, event notification, defining customer-specific AI models and continuous learning. In the real-time AI stream detection part, the Vision AI system can use the customer's factory camera combined with the AI module to perform real-time stream detection of AI image events. It can help customers manage various operations and factory environments and keep track of them anytime and anywhere. Various work situations; in terms of event notification, the Vision AI platform can provide a web version or APP or LINE instant messaging software to provide customers with video records of the events at that time, so that the team does not miss any events, maintains daily production capacity and reduces accidents; in defining customers In terms of exclusive AI models, a variety of basic AI models are available, including 8 detection scenarios (electronic fences, personal safety equipment, construction safety equipment, construction operations, personnel counting, screen availability, smoke detection, pipeline corrosion and damage) , illegal stacking) for use in different industries, customers can build exclusive AI models without spending time writing programs; in the continuous learning part, the Vision AI system can provide customers with the performance and accuracy of AI models, and have the ability to adapt as the environment changes Continuous learning ability.

Vision AI has a simple user interface and intuitive operation. For cross-field industries, this platform has automated and flexible AI capabilities. Customers can build self-defined AI models without spending time writing programs, and Vision AI gives AI models the ability to continuously learn and improve, allowing customers to save the labor cost of building an AI team. In addition, the platform can significantly reduce the manpower allocation for routine inspections required for operational safety management, improve employee safety in the working environment, and reduce on-site accidents/risk factors at various work sites. In the platform operation mode, customers can reduce the risk of manual monitoring operations through remote operations, ensuring normal work operations and uninterrupted production operations. They can also review high-risk operating situations and collect data to assist in the planning and correction of operating processes. In addition, in order to ensure that customers comply with government regulations, Vision AI can help customers control the equipment and safety regulations required in different workplaces at any time through the platform's event notification and management detection.

▲The image analysis AI platform is used in cross-field AI image recognition technology

Generally, for industrial safety inspections in the chemical industry, most rely on the naked eye of personnel to regularly inspect pipeline abnormalities. It takes an average of 100 minutes to scan an area each time, which is time-consuming and laborious, and the pipeline location is difficult to visually observe, which may cause Employees are exposed to accidental risks in various work safety environments. In order to reduce the pain points of industrial safety inspections in the chemical industry, Xinyunlinke assists well-known domestic chemical industry players by using an automated image analysis AI platform, combined with customized virtual electronic fences, and using in-plant cameras to configure AI pipeline leakage modules. , the AI automatic inspection method can effectively reduce the abnormal detection time to less than 3 seconds. In addition, cameras deployed in the factory can automatically record inspection schedules to achieve full-time monitoring, allowing customers to instantly discover and fully control pipelines, minimizing risks. In addition, the automated image analysis AI platform can help customers apply fire warnings in factories. It is conservatively estimated that the return on investment can be less than 9 months to pay back the investment. The longer the platform is used, the higher the cost-effectiveness.

Build an automatic learning image analysis AI platform for Mobility as a Service in various fields

Xie Yuanbao observed that the biggest challenge facing the entrepreneurial culture of software companies in Taiwan is that young new entrepreneurs or employees in Taiwan do not understand the entrepreneurial model and lack the awareness to regard themselves as part of the company owners. This has caused It is a pity that your future is unclear or you have a past-experience mentality that prevents you from staying competent in a new start-up company for a long time. I believe that the essence of true entrepreneurship lies in every employee rolling up their sleeves and working hard, so that they can truly enjoy the fruits of entrepreneurial profits. Otherwise, for young entrepreneurs or employees who often change tracks, it will be like a rolling stone that gathers no moss. , I am unable to take a deep root on the road of entrepreneurship, and I lose my ability to solidly accumulate financial independence.

Regarding the business promotion challenges of Xinyun Linke, Xie Yuanbao said with emotion that because the Taiwan market does not have a deep understanding of AI software applications, it relies more on open source AI visual analysis or machine learning and other resources on the market, but in fact These AI technology resources are limited in their ability to support customers' AI model needs, resulting in uneven quality of AI visual analysis software in the market. Therefore, the impact is more indirect on Xinyunlinke's ability to truly provide customers with professional and data-centric AI image analysis services, and it also reduces the company's original business value in customer reference. In terms of technical research and development challenges, the visual analysis AI platform cannot rely solely on AI model experts. It must gather talents in various fields such as cloud, machine learning, data science, front-end and back-end and other professional team combinations to make the platform operate successfully. Xie Yuanbao said that he believes that only through the automatic learning of the visual analysis AI platform, automatic fast and accurate data processing capabilities, and providing customers with complete AI solution services in the cloud, cloud + ground (Hybrid) to pure ground, can we truly Convince customers and stand out from the competition.

Looking to the future, Xie Yuanbao hopes that Xinyunlin Technology can build an image analysis AI platform for Mobility as a Service to automatically learn in various fields (such as self-driving cars, smart warehousing robots, and unmanned buses in smart cities). At the same time, I am also grateful to the support of the Industrial Bureau of the Ministry of Economic Affairs for the smooth landing of Xinyunlin Technology in Taiwan and the opportunity to recruit talents from all walks of life to work together. In the short-term layout, the company will actively cooperate with domestic players such as Hon Hai and TSMC to implement image analysis AI technology in fields such as self-driving cars, smart industrial safety, and smart warehousing robots. In the medium to long term, Xinyunlinke will target the United States, Europe, Japan and other countries as its global market layout, establish investment and cooperation partnerships with major international companies such as Microsoft, and replicate its successful experience and promote it internationally.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」