【2020 Solutions】 Hangte Electronics AI Innovation Applications, Comprehensive Upgrade of Monitoring Technology

Hangte developed AI Cam, offering smart innovative services

The development of monitoring products has undergone breakthrough development due to the advent of artificial intelligence technology; traditional network cameras (IP Cam) have been upgraded to AI network cameras with smart image automatic analysis and response capabilities.

AI Cam not only meets the high-resolution demands of various platforms with image quality but also continuously expands its capabilities based on its smart application properties, thereby creating innovative services in smart imaging applications that keep evolving and being suitably applied in various environments and scenarios.

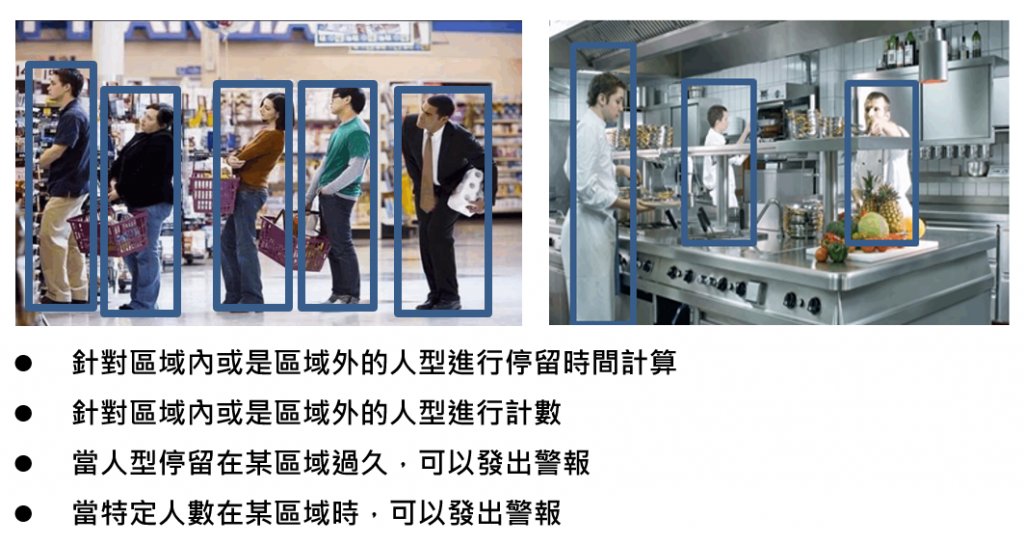

For example, in the use of human detection applications, this smart monitoring feature can separately identify each person in the surveillance video and delineate a specific range as a basis for monitoring decisions, conducting systematic analysis and management; users can calculate the dwell time, count people traffic, and also issue immediate alerts when a designated person enters the monitored range (as shown in the diagram below).

In the aging society with a shortage of manpower, smart long-term care efficiently enhances care quality

According to statistics from the Ministry of Interior, Taiwan has entered the 'aging society' structure. Since 1993, the population of elderly people aged 65 and above has steadily increased from 1,491,000 to 3,312,000 by the end of March 2018; according to estimates by the National Development Council, the elderly population is expected to exceed 20% by 2026, making Taiwan parallel with Japan, South Korea, Singapore, and some European countries as a 'super-aged society'.

In other words, in the future, Taiwan's society may become a structure where one in every five people is elderly, significantly increasing the need for long-term care facilities and retirement centers. Given the trend toward an aging population, the manpower resources for caring for the elderly will inevitably diminish over time.

The solution to the aforementioned shortage of manpower for long-term care needs is to optimize the operation of long-term care institutions using artificial intelligence technology, particularly by utilizing AI network cameras with smart image auto-analysis and instant response capabilities, combined with the Internet of Things (IoT) automatic connection features to promptly identify problems and handle them effectively, embodying a high-efficiency smart service application.

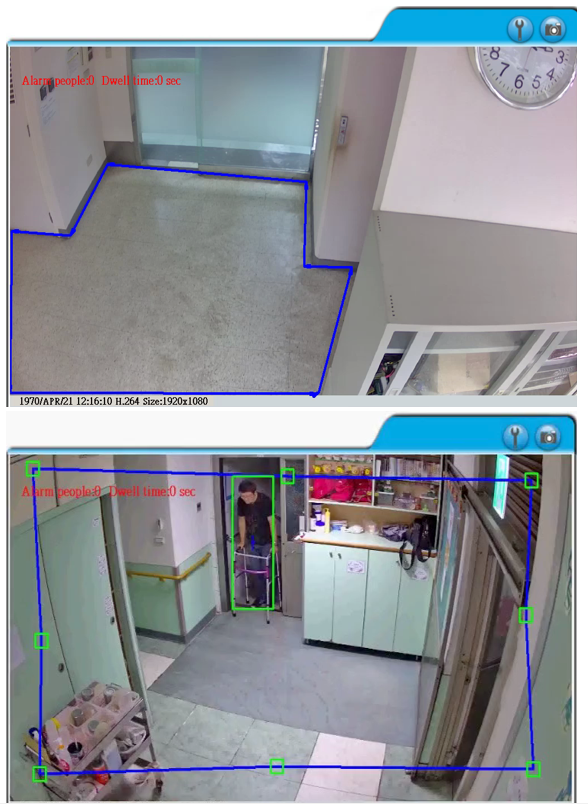

In the smart operation system of long-term care institutions, we can set up a people counting function to calculate the daily traffic, using this data as a reference for observing the dynamics of personnel entering and exiting a designated detection area, useful for calculating attendance or foreign visitor flow, and adjusting door threshold times or work schedules accordingly; additionally, the electronic fence feature can define and secure specific areas, immediately alerting the management if an unauthorized visitor breaches the area, coupled with fall detection to set up designated areas for the care recipients prone to falls, immediately notifying the caregiver if an incident occurs within the detection range (as shown in the diagram below).

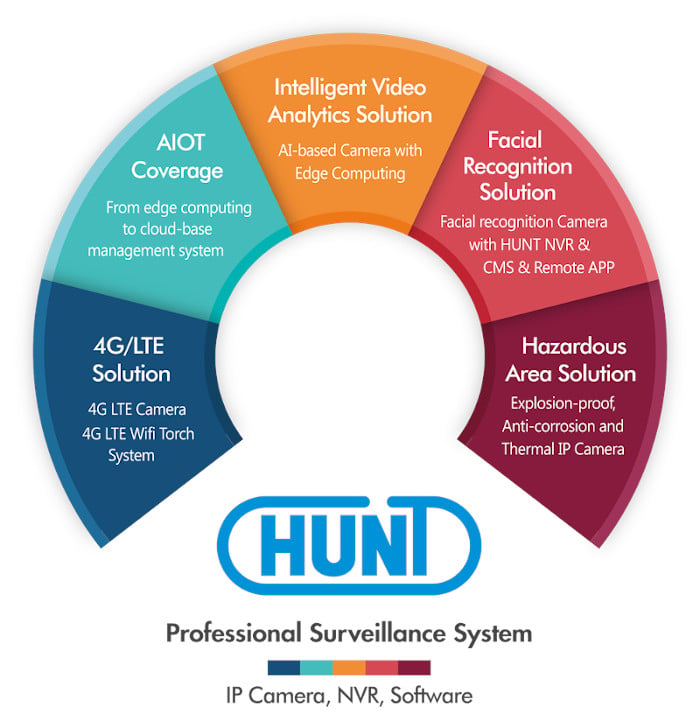

Edge computing smart imaging, cloud IoT innovative services

The application of artificial intelligence combined with the Internet of Things in monitoring scenarios is not limited to potential suspects or dangerous individuals; in retirement and long-term care environments, AI surveillance can also enhance monitoring and integrated management of resources.

Hangte Electronics, leveraging over thirty years of industry experience and R&D capability in monitoring imaging technology, successfully combines Internet of Things technology (IoT) and Artificial Intelligence (AI), not only making good use of cloud computing to reduce installation and management costs of surveillance environments but also greatly enhancing the overall monitoring effectiveness of security systems; by utilizing edge computing to provide image preprocessing capabilities and coupling it with AI smart image analysis technology for various image recognition and instant analysis of monitored subjects' behavior, automatically linking response mechanisms to correspond to triggering events, fully dedicated to crafting innovative service solutions for smart surveillance 2.0 for clients.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」