【2019 Application Example】 How can public restrooms rely on IoT and cloud technology to become cleaner, solve 70% of customer complaints, and increase efficiency by 120 times?

IoT smart restroom: A revolution of clean, power-saving, and convenient new smart restrooms

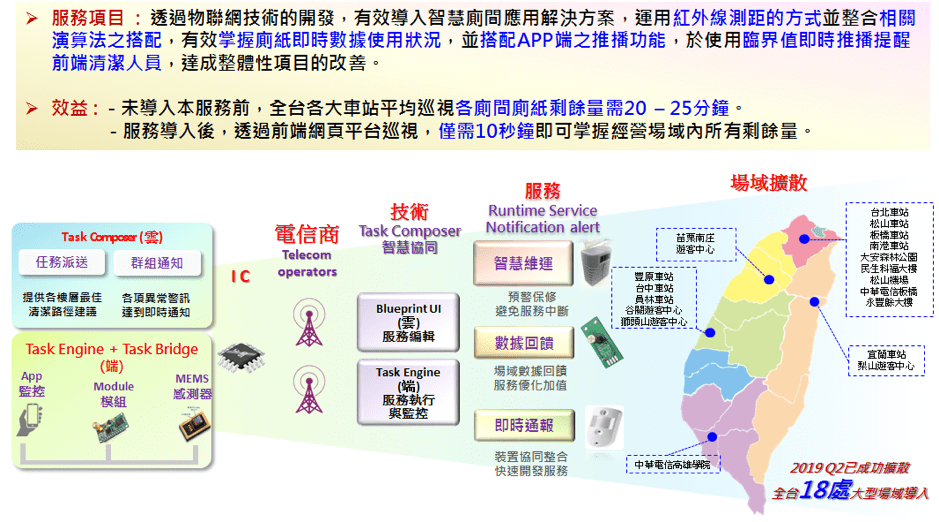

Six sensors are used to detect toilet paper, hand soap level, water leakage, odor, people flow, and toilet usage conditions, and combined with NBIoT transmission, cloud system, and LINE robot. It greatly reduces customer complaints and improves the efficiency of replenishing consumables in restrooms. Coupled with real-time notifications, it can prevent illegal smoking in restrooms and improve safety. Users will no longer face the dilemma of wet, dirty, smelly restrooms, or toilet paper running out, greatly upgrading their experience.

What is your impression when you walk into a public restroom in a popular tourist area? No hand soap? No toilet paper? Or even a dirty, smelly, and leaking restroom? The IoT big data smart restroom solution of the Institute for Information Technology (III) solves all inconveniences of restrooms all at once.

According to statistics of the Environmental Protection Administration (EPA), Executive Yuan, there were more than 43,000 public restrooms registered and managed in Taiwan as of the end of September 2019, but the entire EPA only had over 34,000 people. Cleaning and managing such a large number of sites is obviously not an easy task. Coupled with the inevitable arrival of an aging society, the number and quality of personnel cleaning restrooms will inevitably encounter unprecedented bottlenecks. The introduction of effective service processes and assistance of technologies has become a major issue that must be faced sooner or later.

The IoT smart restroom service solution demonstrated by the III at over 20 restrooms around Taiwan may provide a good direction for us to solve this problem.

Overwhelming number of customer complaints, four major problems, and three solutions of the III

In 2016, when the MRT Songshan Station, which is connected to the train station, was officially opened, the public restrooms that were already at full capacity resulted in serious customer complaints due to the overwhelming use. Songshan Train Station, which originally had an average daily passenger volume of only 40,000, was already near a bottleneck in service capacity. After the connected MRT Songshan Station was opened, the number of passengers increased to 70,000. The restrooms that were already near full capacity were completely unable to cope with the additional passenger volume after the MRT station was opened.

Cao Xueqin once wrote a classic line that touched people's hearts in the novel "A Dream of Red Mansions": "When a wall is about to collapse, everybody gives it a shove" may be able to describe this phenomenon: The toilet paper and hand soap in each restroom was never replenished in time, the sinks were dirty, and the toilets could never be cleaned in time. There was an overwhelming number of customer complaints about the restrooms as a result. In addition, the public restrooms of Songshan Train Station are closer to the main passageways of passengers than the public toilets of MRT Songshan Station. At this point Songshan Train Station had to face and solve this problem.

Since Songshan Train Station has worked with the III for a long period of time, it commissioned the III to help solve this troublesome problem.

Edison has a famous saying: "If I find 10,000 ways something won't work, I haven't failed. I am not discouraged, because every wrong attempt discarded is another step forward." The first thing that the III needs to do is conduct pain point analysis and think about the underlying problem. After reviewing customer complaints and discussing and analyzing them with front-line cleaning service companies, the III found four problems and three solutions:

The four problems are: Toilet paper and hand soap are not promptly replenished, sinks are damp, and the space has a foul smell.

The three solutions correspond to these four problems respectively: 1. Delicacy management of consumables such as toilet paper and hand soap. 2. Digitize the key performance indicators (KPI) in the service process, such as the dampness of the sink, or the odor concentration in the space. 3. Use new Internet of Things (IoT) technology to implement the first two solutions, and assist big data and cloud technology in achieving efficient site cleaning management.

"Technology features and R&D process"

The combination of six key sensors with IoT cloud motherboard and big data, thoroughly resolving 70% of customer complaints and increasing efficiency by 120 times.

I. Delicacy management of consumables

To achieve delicacy management of toilet paper and hand soap, the first step is to develop sensors to detect these two consumables.

Starting in 2017, the III began to design the first infrared toilet paper detection module. The module mainly uses the physical characteristics of toilet paper usage habits for detection: Under normal use, toilet paper is placed on an iron drum holder, and its thickness slowly becomes thinner as it is used.

This module requires the combination of a position sensitive detector (PSD ), infrared emitting diode (IRED), and signal processing circuit (SPC) to effectively determine the length of toilet paper with accuracy reaching one decimal place.

When the detection module was first developed, there were no designs that could be referenced, so sensor selection, circuit board designing and planning, sensor programming, and even the light-cured 3D printed casing design were all completed in the III.

However, despite overcoming all the difficulties in designing and producing the toilet paper sensor, there was no way to foresee that fixing the sensor in place would be the most difficult problem.

The III team shared with us: “At first, we used hot melt adhesive to fix it in place, but cleaning personnel needed to open and close it every time they replenished toilet paper. The sensor fell due to too much vibration and not being firmly fixed in place.

The worst situation was in the women's restroom: When a female passenger was using the toilet, the sensor was not properly fixed in place and fell. Don’t you think this sensor looks like a pinhole camera? If something like this suddenly falls on the ground in the women's toilet, how bad do you think it will be? (laughs)

Fortunately, our superiors supported us, and we continued to develop the technology until we were able to successfully fix the sensor firmly in place. Otherwise, this project would have been aborted a long time ago."

After the toilet paper detection module was launched, an inspection of toilet paper usage that once took cleaning personnel 15-20 minutes to complete now only takes 10 seconds by opening the app. This greatly improved efficiency by 120 times.

Now that the consumption of toilet paper has been solved, the next problem is detection when hand soap is at a low level.

Unlike toilet paper, the amount refilled each time for hand soap isn't always the same. Because the design philosophy was to use the lowest cost and most stable components to complete this function to facilitate future scaling, a common Hall sensor was chosen. It was mounted on the exterior of the soap dispenser to achieve the detection of low soap levels.

The principle is actually very simple. Once the liquid level is lower than a certain percentage, the Hall effect sensor can sense the change in voltage from electromagnetic induction of the liquid level. The sensor sends a signal to the back-end cloud server, and then the server then sends a message to cleaning personnel the same as the toilet paper sensor.

II. Digitization of key performance indicators (KPIs) in service processes

If the sink is wet, water will often seep onto the floor. In addition, the bottom of passengers’shoes will inevitably carry dust, so the floor will become dirty when they step on the wet floor. Visually, this will give people a sense that the “restroom is dirty." However, it is impossible to have cleaning personnel on duty in the restroom at all times, so a special sensor is needed to detect this situation.

The III uses the resistance characteristics of thin film resistors. When there is liquid on the surface of the thin film resistor, it will lower the overall resistance value and further change related values of the analog signal output. In this way, moisture can be detected by simply laying thin film resistors on surfaces that often become wet. For example, next to the windowsill or on the sink.

However, since sensors are relatively expensive and scratches will damage the performance of the sensors, this moisture detection sensor is only used in specific public restrooms.

Apart from looking dirty, if a foul smell comes from a public restroom, people will think it is dirty even if it looks bright and clean.

However, odor detection is not that easy to solve.

At first, we searched all kinds of sensors in Taiwan and overseas to find this "electronic nose." We eventually found a suitable MEMS chip in the product line of a major Japanese manufacturer that specializes in the production of gas sensors.

The III started from breadboard testing, circuit design drawings, to outsourced chip production, taking nearly six months to complete the design of the sensor.

Furthermore, in the process of developing smart restrooms, we also received requests to develop other modules, such as people flow detection and usage detection.

During the development process, we found that users may accidentally close the door of some accessible toilets after use and forget to turn off the lights, so it seems as if the toilet has been occupied all day long. However, people who really need to the toilets are blocked outside the door of accessible toilets that are actually vacant. This problem was relatively simple. The engineer found a ready-made people flow sensor module and installed it under the sink, and the problem was easily solved.

In addition, environmental protection and carbon reduction requirements are hard to meet for some remote public restrooms, such as Tri-Mountain (Lishan) National Scenic Area. Due to the remote location, responsible personnel must turn on the lights every day at work and turn off the lights when they get off work. Sometimes not many tourists use the public restroom all day long, but all the lights and equipment are still on all day long, which is a waste of electricity.

Generally, commercially available sensors are very dull and will turn off the power as soon as the set time of 30 seconds to 10 minutes is up. Such a sensor may be adequate at home when only one person uses the toilet. However, in a restroom that can easily reach 60 ping or above, several detectors will be needed to work together to ensure whether there are still users in the restroom. This is another problem without a commercially available solution. The III had no choice but to integrate multiple sensors and develop algorithms on the MCU to solve this problem.

III. The introduction of new IoT, cloud, big data, and 5G NBIoT technologies

On the path of innovation, there are always difficulties waiting for engineers to overcome. In the process of solving problems as they come, we also refined the solution step by step, making it cheaper, more reliable, and more convenient.

After the sensors described above were completed, the system gradually generated new problems for the III to solve. For example, the barrier of user habits, power consumption issues, cost issues, etc.

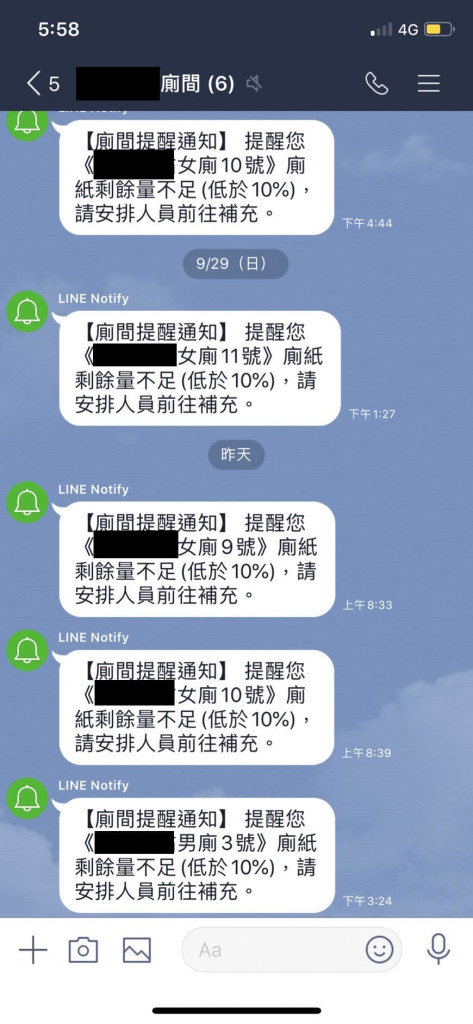

The app was changed to a LINE group robot to become more aligned with user habits

When the public restroom of about 60 ping at Songshan Train Station was completed for the first time in 2017, MCU and WIFI communication were used to monitor and transmit data to the server around the clock. After the system determines an abnormality, it uses the mobile app developed by the III to notify cleaning personnel.

This design seems to be impregnable at first glance. However, the average age of on-site cleaning personnel is over 50 years old, no one used the dedicated app, and front-line personnel often deleted the program within a few days of use. There is a whole set of sensors monitoring, but no cleaning personnel actually use it. User habits are often the biggest obstacle to the introduction of new technologies.

After conducting user interviews we found that the cleaning personnel of every public restroom have a LINE group.

The III team mentioned: "Knowing that they ( cleaning personnel ) have a LINE group makes things easier!

At first, we cautiously asked the cleaning personnel if they would invite a robot "new colleague" to help inspect toilet paper and determine abnormalities in the restrooms.

At the beginning, the cleaning ladies were a little skeptical. When they discovered that this robot "new colleague" was very useful, they fell in love with it."

Due to cost, environmental protection, and convenience issues, WIFI was upgraded to NBIoT communication protocol.

WIFI is fast and has wide bandwidth. A restroom has a men's room and women's room, which requires two separate systems for monitoring, and each system needs an independent 4G network to connect to the cloud system. Therefore, the construction and communication costs are relatively high, and the power consumption is also relatively high.

At this point, readers may have questions: Public restrooms are all set up in public spaces. Is there no public WIFI network available?

The III team gave us a very in-depth answer: "Actually, almost every public space has a WIFI network that can be used. However, sharing WIFI with other people is prone to interference, and IoT devices are simple and lack security control mechanisms. If you use public WIFI, there is a certain degree of security. risk.

Therefore, in our solution, we still designed a closed WIFI communication system to solve the communication problem.

In addition, since a WIFI base station can only support 20-30 nodes, a women's room with 18 toilets requires a separate systems. Coupled with the fact that it is separated by a concrete wall, the signal will be very weak and even affect the stability of the signal. Therefore, a public restroom installing two systems is mainly due to stability considerations rather than cost considerations."

In densely populated areas, using WIFI to transmit data to the server is not too troublesome. However, when smart restroom systems are beginning to be applied to restrooms in remote areas, such as Lishan, Guguan, Shitoushan and other public restrooms of national park visitor centers, maintaining network connection is indeed a difficult problem.

Fortunately, new generation mobile communication networks of 5G includes narrow-band Internet of Things (NBIoT) specially designed for the Internet of Things. The III is the first in Taiwan to develop Taiwan's first NBIoT MCU control system designed for smart restrooms using the NBIoT chipset of a domestic chip manufacturer.

In addition to the significant cost reduction, this system is also very energy efficient, requiring only 1/6 of the power of the original WIFI system. The most important thing is that compared to traditional WIFI, which requires a relatively stable 4G signal connection, this system has wider coverage and allows communication deep in the mountains and out in the wild. This allows wider coverage of smart restrooms in the future without being limited by network signals.

IV. "Effect Analysis and Future Outlook"

IoT smart toilet: A revolution of clean, power-saving, and convenient new smart toilets!

As the complete set of sensors, cloud system, NBIoT, and LINE robot are gradually launched, the benefits are clear.

In the case of public restrooms at Songshan Train Station, from being overwhelmed at first to greatly reducing the number of customer complaints by 70%, the time required to inspect toilet paper use was shortened from the original 15-20 minutes to only 10 seconds. Once an abnormal situation occurs, it has gone from being undetected to the prompt notifications today.

Interestingly and unexpectedly, this entire system also brings the added benefits of safety and thorough enforcement of tobacco hazards prevention laws. When a toilet is occupied for more than 40 minutes, a warning will be sent to the cleaning personnel group. Hence, when a user occupies a toilet for too long, cleaning personnel will knock on the door. This greatly improves safety.

In addition, odor detectors are also very sensitive to the smell of smoke. Since smoking is prohibited in national parks, tourists sometimes sneak into public restrooms in remote areas to smoke. In public restrooms of national parks, once the odor detector detects the smell of smoke, it will play a voice message about the Tobacco Hazard Prevention Act to let tourists clearly know that smoking in public restrooms will result in a fine of NT$2,000 to NT$10,000. Since the installation of odor detectors, the number of users smoking secretly in public restrooms has significantly decreased.

The "smart public restrooms" at Songshan Train Station won the "Golden Way Award" from the Ministry of Transportation and Communications for overcoming various difficulties, which made it famous. From a constant stream of customer complaints to model public restrooms that the public sector has enthusiastically visited, the additional workload on the case officer from handling group visits is actually a luxury to be worrying about.

Future Outlook

The system has proven its stability and cost effectiveness during the three years of R&D and field experiments, and has now been successfully transferred to domestic system integration companies. The III also hopes that this system can be expanded in the future, and the technology can even be transferred to Europe and the United States.

In addition, on the basis of stable and reliable data flow and communication connections, the introduction of big data for analysis may make the deployment of manpower more delicate, and the problem of uneven work distribution can be expected to be fundamentally corrected.

Facing the arrival of an aging society, NBIoT communication systems, combined with various IoT sensors, may be able to bring us a healthier and safer living environment. Some repetitive tasks that traditionally relied heavily on manpower can also use technology to greatly improve efficiency.