【2024 Application Example】 AI-Based PCBA Surface Defect Detection Improvements

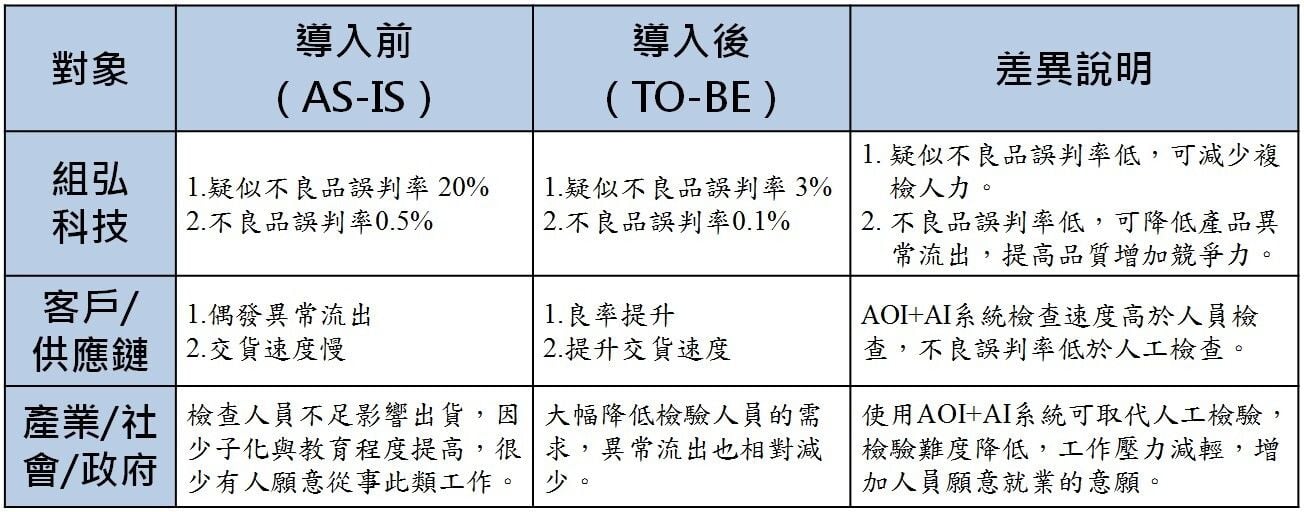

With the introduction of theAOI+AIWith the introduction of the system, we can improve product yield, reduce costs, and from a business perspective, increase customer trust and sales revenue. Moreover, AIit has advantages that are difficult to imitate, unlike other equipment that can be bought with money, making it hard for our competitors to catch up with us.

Our company's current development

We are committed toIOTsmart manufacturing; our systems already include smart materials systems, environmental humidity control systems, anti-miscarriage systems, smart procurement computation systems, smart inventory systems, solder paste management systems, and production management systems. We have asked other manufacturers about the possibility ofAIinspectingPCBAsurface defects, each hoping that we would purchase their equipment, but none were effective upon verification. After discussing with IT service providers, we defined it asAOI+AIa feasible operational model.

Tzuhong Technology has invested inAOI+AIan inspection plan to checkSMTtext on components, solder joints, polarity, missing parts....and usingAIto replace manual learningAOIand define the 'potentially defective' parts, enhancing productivity and reducing misjudgment rates.

Industry pain points

Taiwan faces a severe labor shortage, especially those willing to perform visual inspections are few and typically older, increasing the frequency of missed inspections. Thus, the most critical bottleneck in the pursuit of high-quality electronics has become post-production inspections. Previous consumer products with undetected anomalies were acceptable within a certain ratio. However, in the automotive industry today, undetected defects could lead to fatalities; hence, the automotive industry has extremely high quality demands. To survive in the automotive supply chain, we must address the issue of undetectable anomalies.

Moreover, as wages in Taiwan continue to rise, we can only endeavor toAIreplace traditional manpower with technology, otherwise, even if the anomaly leakage problem is resolved, the relatively high labor costs will still prevent competitiveness in this industry.

Application technology and explanation

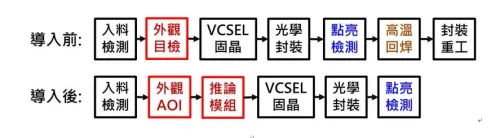

Initially,(Figure 1),PCBUpon emerging,Reflowsystem, it will undergoAOIwill undergo inspection, dividing into 'suspected defective' and good products. At this point, the 'suspected defective' portion accounts for20%manual review for these20%parts, further classifying the 'suspected defective' portion into good and defective products. With

We aim to leverageAItechnology, to shift from manual re-inspection of these20%technology, we aim to replace manual review of 'suspected defective' products withAIand after review, the results still yield 'good' and 'suspected defective' products, but now 'suspected defective' comprises only3%thus reducing the workload of Tzuhong's employees from20%down to only3%In theory, it isAOIIn theory, after inspection, it is further reviewed byAIbut it appears to go throughAOIonly, so we call this technologyA0I+AIDetection(Figure 2)。

The operator will place the testPCBboard intoAOIthe inspection equipment, outputtingAOI

information on defective products, then manually re-inspect one by one to determine if they are defective.

The operator will place the testPCBboard intoAOIthe inspection equipment, outputtingAOIinformation on defective products after,

then proceed byAIfirst performingAOIre-assessment of defective products, outputtingAIinformation on defective products afterward,

then manually re-inspect one by one to determine if they are defective.

Process differences

By introducing theAOI+AIsystem, not only can we enhance the efficiency and yield of visual inspection personnel, we also have this timeAIexperience in system introduction, we will also incorporateAIthe use of big data into Tzuhong's existing smart manufacturing systems, further enhancing the performance of our smart manufacturing systems and reducing the pressure on employees.

Promotion strategy

(1) Similar field diffusion: allSMTmanufacturers face bottlenecks in inspections leading to shipment delays; introducing this system can solve the severe labor shortage issue and enhance shipment speed and quality, allowing self-promotion to customers or through equipment dealers to cater to relevant needs.

(2) Cross-industry expansion plans: negotiate withAOImanufacturers to directly integrateAIthe system intoAOItheir systems, enhancing their market competitiveness.

Profit strategy

(1) In collaboration withAOImanufacturers, collect licensing fees.

(2) Direct sales toSMTthe manufacturing industryAIsystems.

(3) ProvideSMTmanufacturing industryAOI+AIsystem subscription model

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-12-09」