【2020 Solutions】 Always Measure Temperature, Prevent Wandering, AI Helps with Wuhan Virus Isolation

As the novel coronavirus epidemic continues to spread, the number of quarantined and isolated individuals steadily increases, becoming an 'unbearable weight' for managers. SITU Technology, along with Myte Electronics, Ai Micro Science, and String Cloud Technology, have collectively developed a 'Home Isolation Personal Location Tracking System' for COVID-19, addressing the issues of isolated individuals wandering and holes in epidemic tracking.

On the afternoon of February 12, 2020, as the novel coronavirus epidemic continued unabated, home-isolated individuals were seen wandering around, causing widespread alarm, with anxious faces hidden beneath white masks. A 'Public Cloud Location and Monitoring Seminar' held in Taipei unexpectedly helped forge a significant epidemic prevention coalition.

Formed by a coalition of established and startup companies including SITU Technology, Myte Electronics, Ai Micro Science, and String Cloud Technology, they introduced the COVID-19 'Home Isolation Personal Location Tracking System'. In the abodes of those quarantined, whether in centralized isolation spots or home setups with temperature monitoring platforms, an automated reporting process alerts immediately if abnormalities are detected, significantly reducing the burden on epidemic staff and preventing quarantined individuals from easily leaving their premises, thus plugging the gaps in epidemic tracking.

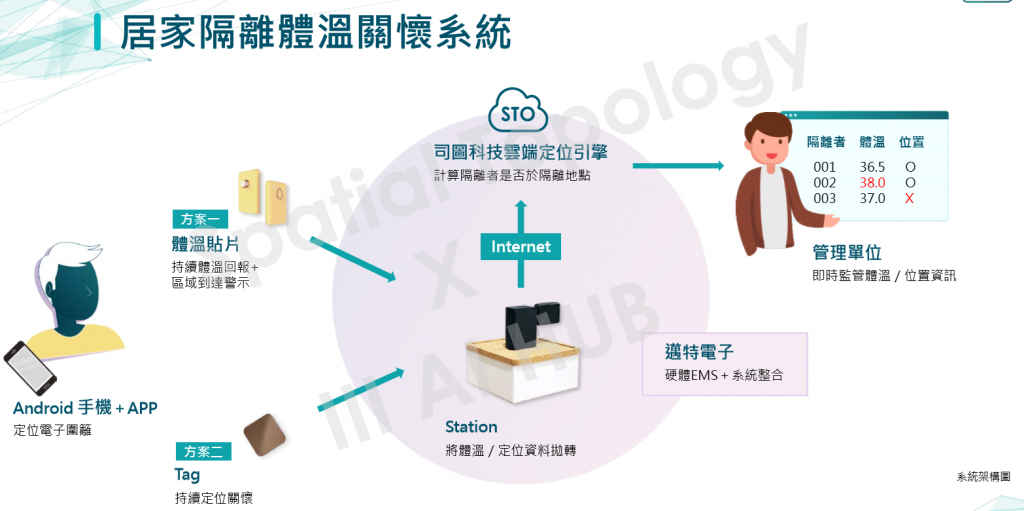

▲Home Isolation Temperature Care System Architecture Diagram

Home Isolation Wandering, Epidemic Phones Not Enough

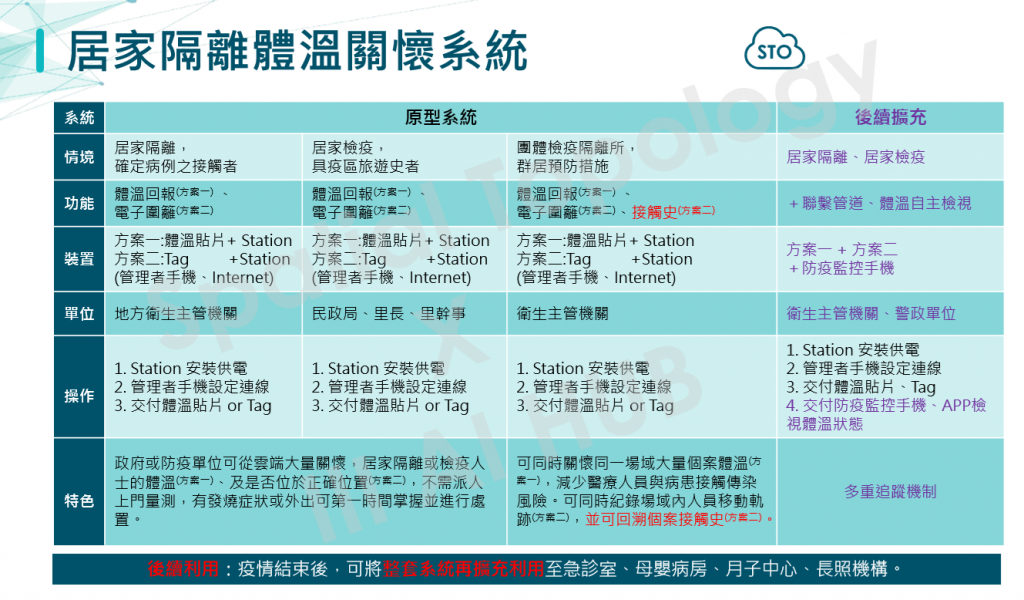

As the number of confirmed cases of the coronavirus rises, in order to effectively prevent community transmission, the Central Epidemic Command Center has specified that all entrants must undergo individual home isolation, home quarantine, and self-health management; those in home isolation and quarantine must rest at home for 14 days and must not go out, during which community leaders and police officers should ensure at least two temperature checks daily.

However, as the epidemic intensifies and the number of people requiring a 14-day home quarantine skyrockets, there is a dire shortage of equipment and personnel. This includes 2,000 location monitoring phones provided by the government being insufficient; additionally, the limited number of epidemic personnel face increasing work pressure, urgently necessitating the use of technological tools to aid the situation.

Shih-Juan Lin, founder and CEO of SITU Technology, explains that the COVID-19 'Home Isolation Personal Location Tracking System' is divided into hardware and software components. The hardware includes a temperature patch from Ai Micro Science and an unlimited location tracking device (USB receiver) provided by String Cloud Technology. The patch, which must be placed in the armpit of the quarantined individual, is capable of measuring temperature 24 hours a day; the receiver uploads temperature and location data to the SITU Technology's cloud positioning engine. This data is analyzed to track temperature trends and accurately predicts the likelihood of diagnosis.

▲ Home Isolation Temperature Care System Comparison Chart

Temperature Measurement + Indoor Positioning System Reduces the Likelihood of Community Infections

SITU Technology was officially established in 2015, with co-founders from various fields including indoor positioning, robotic platforms, imaging graphics, machine learning, and cloud computing. Shih-Juan Lin states that the unified epidemic phone GPS systems, whether used for centralized quarantine, centralized isolation, home quarantine, or home isolation, have two drawbacks: the resolution is too high; and they cannot track vertical movements, meaning that they cannot detect movements from one floor to another, or from one room to another, which greatly increases the potential for community transmission.

Compared to traditional methods, SITU Technology's positioning sensing system uses various devices, including optical lenses, LIDAR, and ultrasound, to sense wireless signals at each point like an indoor Google car, accumulating extensive and comprehensive data to build an accurate floor plan. Simply said, by crossing-comparing wireless signals received by multiple indoor receivers and using AI deep learning, the positioning can break through spatial restrictions and achieve greater accuracy.

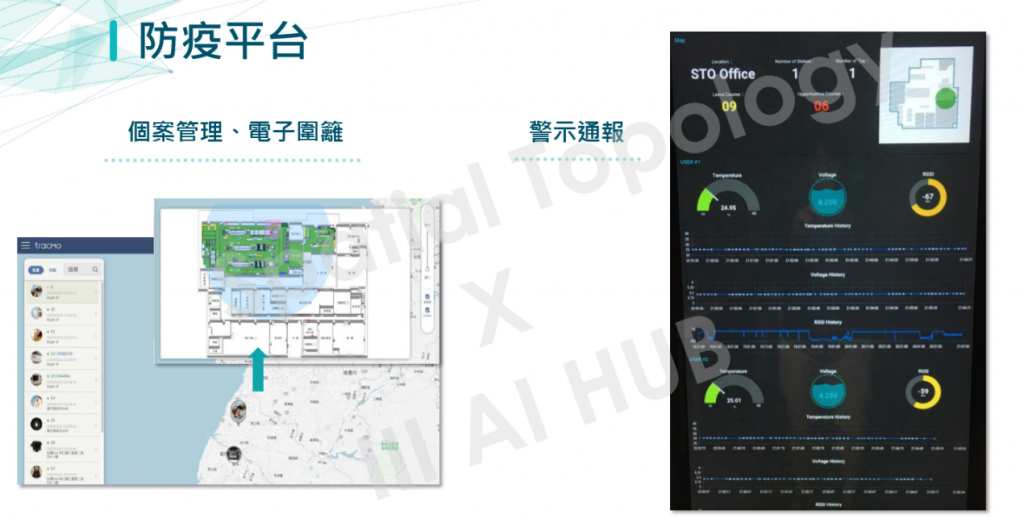

In addition to precise positioning, by analyzing the mobility tracks of isolated individuals and groups and tracking their contact history, it is further possible to grasp the virus transmission routes, offer early warnings, and avoid community infections.

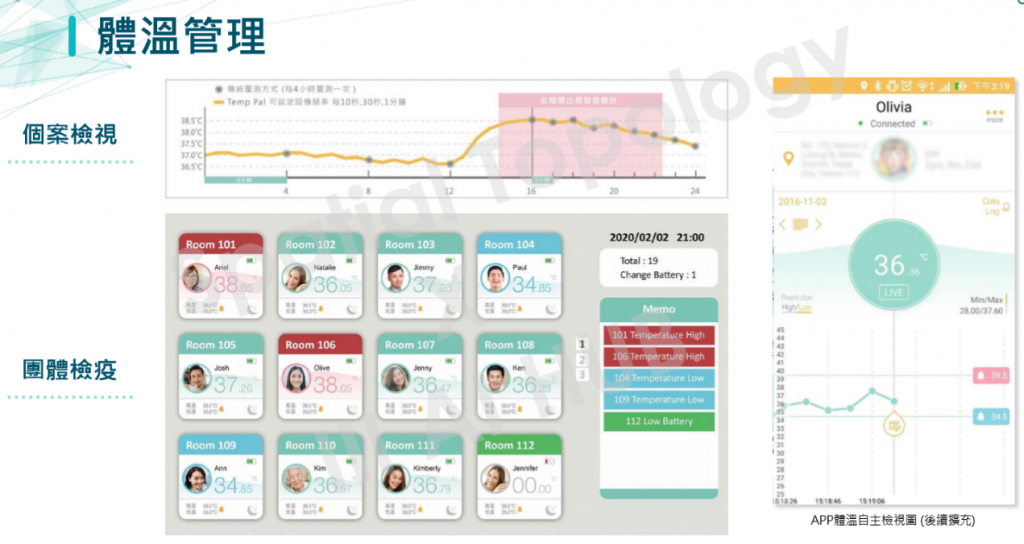

On the management side, computers and large electronic displays can observe the temperature, battery usage, and signal strength of the group patches (isolated individuals). Once it is detected that an isolator has left their designated location, an automatic alarm signal is immediately triggered, allowing management personnel to take immediate action. On the other hand, isolators can also record their own temperature changes on their phones, and in the event of an abnormal situation, they can immediately notify the quarantine unit for further checks.

▲Epidemic Platform Diagram

This system was conceived and formed on February 12, and within just over a month, has been empirically tested in centralized isolation facilities in Taipei City and New Taipei City of around 50-bed scale, with effective implementation. In the future, there is the potential to expand to factories, offices, and other larger scale, high-risk areas for temperature management. After the epidemic, this system can also be expanded for use in emergency rooms, maternity wards, postpartum centers, and long-term care institutions.

▲Isolator's Temperature Management Interface

Amid the ongoing global epidemic, the COVID-19 'Home Isolation Personal Location Tracking System' may have the opportunity to be exported overseas, becoming a global market aide for home isolation and medical quarantine.

▲SITU Technology Team

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」