【2020 Solutions】 AI Press Releases in 20 Minutes - SparkAmplify Bridges Brands and Media for Accurate Exposure

What should small and medium-sized businesses or startups that want to export their products do when they lack PR resources, media exposure, and journalist contacts? SparkAmplify, a company that builds global market platforms using big data, has created a precise media marketing platform SaaS that aggregates data from over 80,000 global media journalists. With AI technology, it analyzes data and generates press releases within 20 minutes, matching them with accurately targeted international journalists to greatly increase exposure and achieve marketing goals internationally.

SparkAmplify's main service is a brand-media matching marketing SaaS platform. Since its launch in 2018, it has continually analyzed international media trends and has already analyzed over 3 million international media reports, helping more than 1,200 companies from 25 countries achieve precise media exposure. It has partnerships with major events such as CES and Computex, as well as famous incubation accelerators like TechStars, BootUp, Taiwan's TSS, Garage+.

"Media are searching for news, companies are searching for media." By applying AI data, a balance has been found. Jian-Qun Li, founder of SparkAmplify, explains, "From observing the demands of both suppliers and consumers in the media marketing market, there's a rigid demand for a platform that matches 'brands with journalists' based on both parties’ needs." Thus, SparkAmplify utilizes machine learning Logistic Regression algorithms to filter specific categories of news text and uses the LDA topic discovery algorithm to identify the hottest news trends, rolling out the 'AI Exploration of Media Trends' service.

Generate AI Press Releases in 20 Minutes to Find Suitable Media

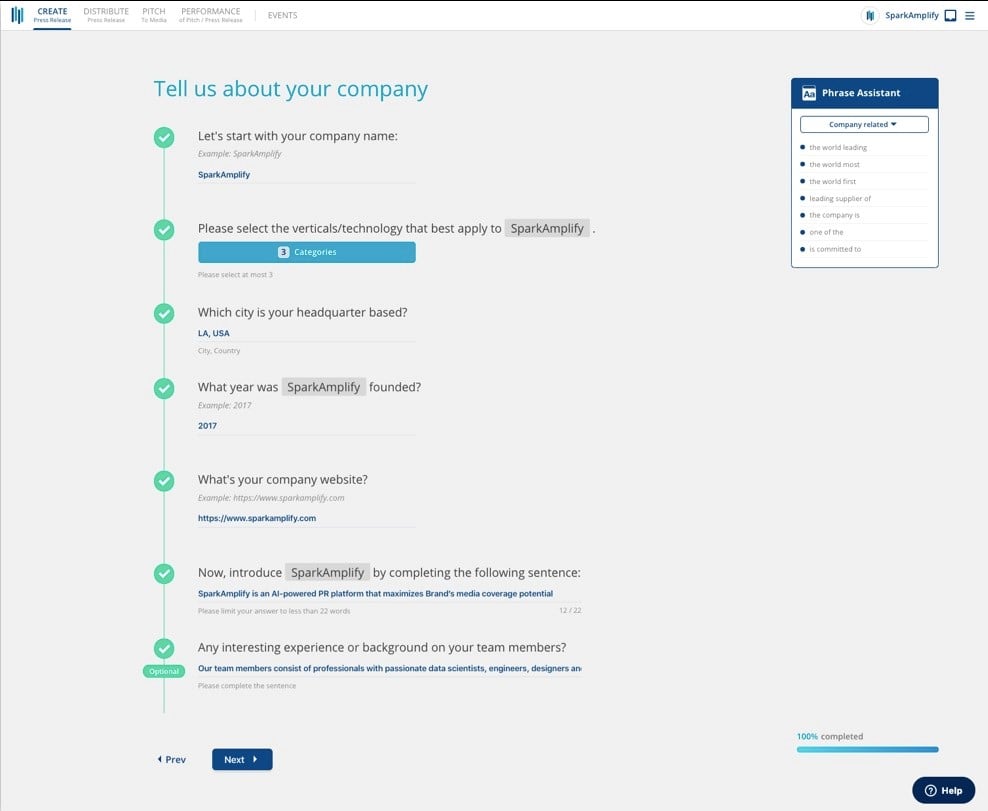

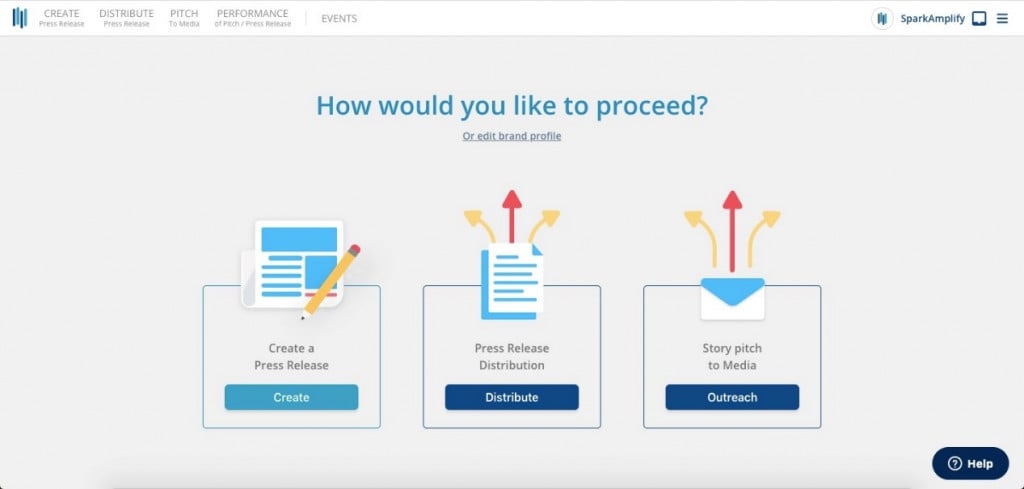

This system service only requires three major steps to disseminate the products or services of brands, small and medium-sized enterprises, and startups on the international market through international media coverage.

● Step One, Material Preparation: SparkAmplify sets up a dedicated brand page where brand managers prepare and upload complete materials including company profile, product names, service features, images, related product diagrams, etc.

● 步驟二、品牌故事撰寫:透過專家系統及運用機器學習Logistic Regression邏輯回歸演算法,將特定類別的新聞文本篩選出來,並透過主題探勘演算法LDA,找出最熱門新聞趨勢,系統會自動按結構、格式、片詞、文法、關鍵字等等,在短短20分鐘內自動生成AI新聞稿,再加以人工優化。

● 步驟三、精準推薦:將公司及產品介紹、新聞稿等,媒合國際媒體共8萬名記者,將對的主題推薦到對的記者身上,主動提供記者報導素材,以增加媒體露出及曝光機率。

▲AI探勘媒體趨勢服務協助品牌公司精準國際曝光

Jian-Qun Li points out that traditional methods of gaining media exposure include holding press conferences or distributing press releases widely. However, at international exhibitions, brand owners and small and medium-sized business leaders might not have sufficient PR resources. Additionally, understanding industry trends and journalists' reporting preferences poses a significant challenge. Aside from the challenges of data collection, extracting meaningful insights and trends can often be ineffective, time-consuming, and labor-intensive. The 'AI Media Trend Exploration' technology can effectively and accurately collect data, use text mining and machine learning to unearth underlying information, and, by executing periodically, keep track of market changes to products.

鎖定科技新聞領域 協助品牌業者精準曝光

善於資料分析的李健群,運用媒體大數據的分析技術,打造以機器學習進行分析的行銷系統平台,專攻歐美市場數據行銷決策與社群行銷,幫助行銷能力不足的的新創團隊,或有想要獲得國際媒體青睞的品牌業主,能以大數據分析找尋適合投放的媒體。

在AI技術的應用上,安普樂發使用NER(命名實體識別技術,Named Entity Recognition)技術來增加不同的屬性。例如人、組織、產品等,最後再透過知識圖譜(Knowledge Graph)建立屬性之間的關係,才能迅速達成預估目標。

由於新聞領域五花八門,包括財經、科技、政治、社會、運動、娛樂、美食、時尚設計等,資料數量眾多,但受限於儲存等資源,無法一一掌握,安普樂發將重點擺在科技新聞領域,與CES、Computex等大型國際科技展緊密結合,提供參展商在公關媒體上操作的資源,爭取國外媒體曝光機會,負責找對的媒體將品牌效益傳達、延伸出去。

▲三步驟完成媒體精準投放流程

SparkAmplify 商業模式主要為訂閱制,每月收取399美元,透過簡單步驟即可輕鬆完成品牌與媒體的對接服務。至於除了英語之外,未來是否會推出中文服務?李健群表示,要跨到落地的語系需要重新建立一套模型,中文又比英文要複雜許多,處理過程要刪除非常多的雜訊。然而,因應中文化的需求日益殷切,未來在資源配置足夠的情況下,有機會也會推出中文服務。

▲SparkAmplify 團隊

▲SparkAmplify 創辦人李健群

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」