【2020 Application Example】 Wending x Woodcut Thinking creates an AI calligraphy assistant, and the cultural heritage of the traditional calligraphy industry is now dawning

The only remaining calligraphy shop in Taiwan, cultural heritage exposed to crisis

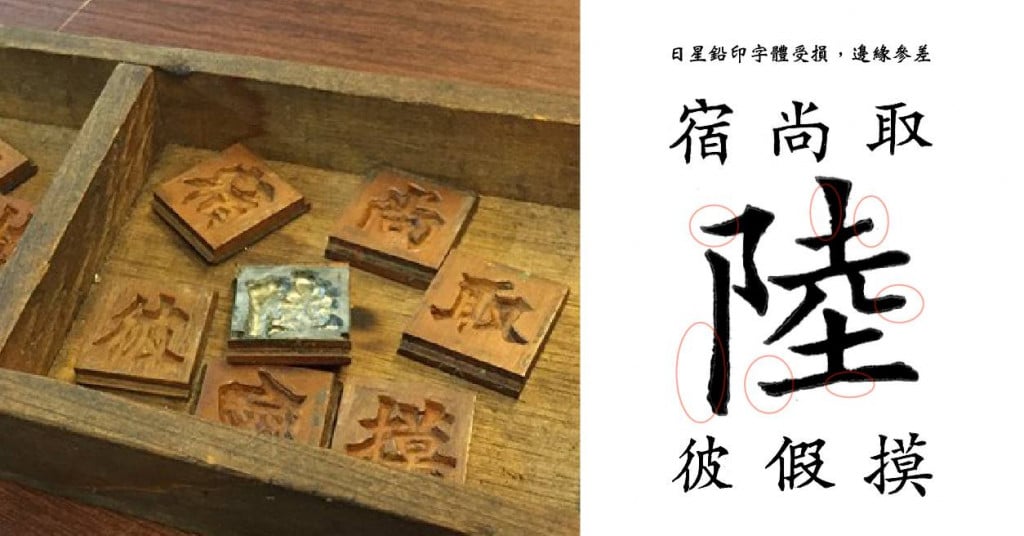

A certain traditional type casting shop in China is the only one "still operating" in Taiwan. It has a sense of mission and hopes to pass on Taiwan's long-standing beautiful letterpress technology. But even if you want to continue to cast characters, the existing molds have been repeatedly cast for more than 40 years, and the "copper molds" used to cast lead characters have been damaged. The tall lettered walls in the store are facing the predicament of being eroded by time.

Each "copper mold" can be used to produce 10,000 typefaces, so it is called the "mother of typefaces." If the handwriting on the copper mold is blurry, the cast lead characters will also be blurry. After printing, there will be incomplete radicals and uneven strokes.

▲In Taiwan from the 1950s to the 1970s, the "block regular script" copper molds used to cast characters played an important role in spreading civilization.

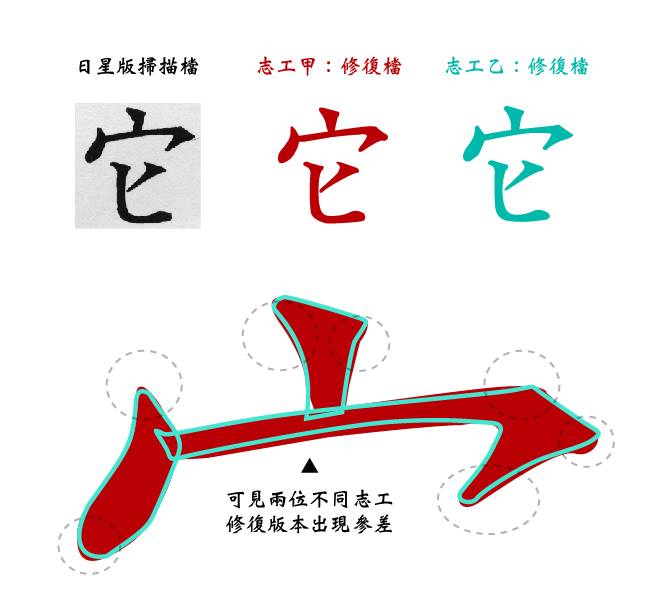

Because of the serious collapse of the copper molds, the owner of the calligraphy shop launched the "Character Bronze Mold Restoration Project" in 2008. Together with a group of enthusiastic volunteers, they first repaired the "Blockcase" copper mold fonts. In the past three years, various discussions and workshops have been in full swing, with non-stop discussions every week, and it seems that the day of replicating the copper mold is just around the corner. However, this optimistic prospect encountered an unexpected crisis and was eventually forced to pause because the characters restored by each person had very different personalities. Although they were beautiful, they did not look like the same set of fonts...

▲It is not easy to develop the "common characteristics" of copper mold font restorers

The long-running "Font Bronze Mold Restoration Project"

After the failure in 2008, it was a huge blow to the type foundry. Because they could not use these fonts, they felt that they were unworthy of the enthusiastic efforts of the volunteers and the most important copper molds continued to be damaged, especially the most important ones in the store. The valuable "block script" copper mold was damaged a little more every time a character was cast, which made Rixing anxious!

▲The damage to the copper mold starts from the "missing corner", gradually breaks into pieces, and finally collapses

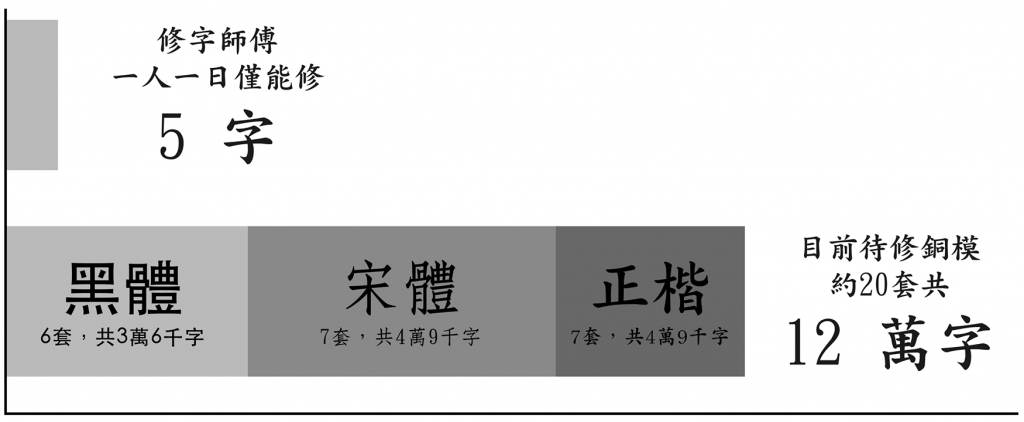

In order to at least preserve the "appearance" of the font before the copper mold was completely destroyed, the calligraphy shop restarted the restoration project in 2016! With the assistance of several important volunteers and the Justfont font team, the most severely damaged "block script" type 1 and some "Song Script" type 1 and 2 were scanned and saved. When resources are available, they can be "Scan the image file" to convert the "font file", and then use the computer to refine it. After that, the 60-year-old boss slowly repaired more than 120,000 Japanese fonts at a rate of 5 characters a day.

In view of the fact that the pace of manual repair is far less than the rate of wear and tear of the copper molds, the type foundry has used more rigorous testing and selection to gather 3 to 4 talents who are willing to assist in long-term restoration. In addition to re-carrying out font education and training, we also added "calligraphy" course training. Most importantly, in order to develop a unified standard for calligraphy repair, these restorers must repair calligraphy simultaneously for months or years, and review the repair results every day in order to reduce errors and achieve consistency. It is expected that three restorers will work together to perform long-term restoration of 5 characters a day; with pre-training, it is expected to reconstruct a complete 4,500-character "block script" initial size font for traditional Chinese characters in 2 to 5 years...

▲How many days does it take for a calligraphy master to finish all the calligraphy?

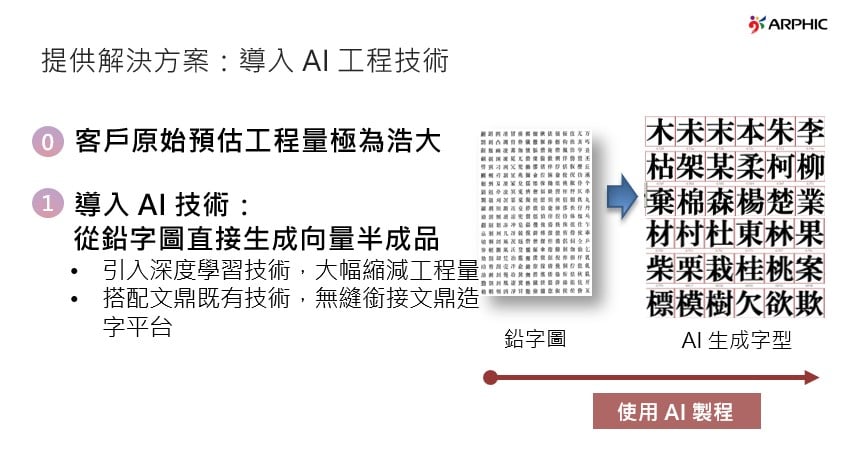

Wending Technology assists, creating AI word-making assistant

Wending uses the world's leading Chinese character creation technology and tools to assist calligraphy industries, and also promotes the AI value-added transformation plan of information service providers through the Industry Bureau's AI smart application service development environment promotion plan, and AI The award-winning new manufacturer Mukesi cooperated with R&D to integrate AI technology to improve character creation productivity, thereby shortening development time and reducing costs.

In the early days, Wending required font designers to create each character from scratch, stroke by stroke. It has evolved to the point where it can use existing character roots to compose characters and pre-assemble complete characters. However, this preliminary pre-assembled character may have overlapping strokes and poor space and thickness. It will also require the designer to spend a lot of time adjusting before producing a usable font product. Through the AI value-added module, the system can learn some of the font styles that have been modified by the designer, and automatically adjust the structure, stroke thickness, etc. of the remaining characters. Finally, the designer can spend less time confirming the quality and With minor modifications, a usable font product can be completed, significantly reducing the time cost of creating characters.

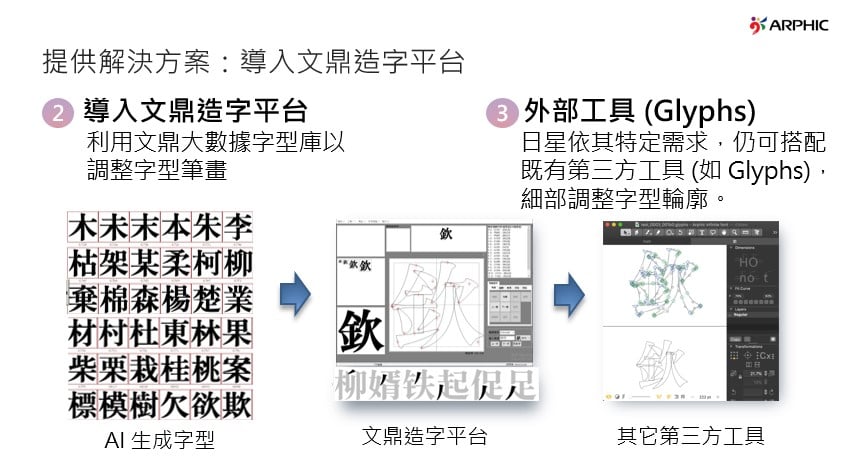

▲Importing Wending’s value-added AI character creation system process-1 of 2 (importing AI engineering technology)

With global font and cross-platform font technical services as its core, Wending Technology provides various font solutions to major manufacturers, system vendors, and government units around the world. Taking the development of new fonts in the past as an example, we have completed a set of It takes a whole year to create a 10,000-word font. The Industrial Bureau of the Ministry of Economic Affairs guided Wending Technology to cooperate with the AI startup Mukesi to learn the font style through AI. It only needs to complete 5,000 words to automatically generate the other 5,000. The fonts are not yet created, and then the quality is confirmed and adjusted, allowing the designer to complete the entire set of fonts in less time, greatly increasing work efficiency by 50%! In the future, we will continue to optimize the character creation module, allowing AI to complete more than 90% of font design, accelerating the production of new fonts.

▲Importing Wending’s value-added AI character creation system process-2 of 2 (importing Wending’s character creation platform)

Wending Technology’s font innovation has been adopted by all walks of life. For example, the 30th Golden Melody Awards used fonts for stage visual design, and Tsai Ing-wen’s presidential campaign team also used platform fonts for presidential election propaganda. In 2019, it was added through AI Value-added transformation of the operating model resulted in revenue of NT$15 million in the first year and is expected to increase revenue to over NT$180 million within 5 years.

Smart font design service platform

Using AI-assisted character creation to lower the threshold of font design, it can be transformed into a "smart font design service platform" in the future, providing designers with self-created fonts, and also serving corporate font design, helping designers achieve what is otherwise impossible. The complete set of font development completed by an individual can also achieve the division of labor between design and development in the professional field of character creation, and become the first step to the success of font OEM, which will have a significant impact on the design and application of fonts.

The iFontCloud font library with AI added value has changed the original operating model, from being limited to font design by Wending Technology’s internal designers to breaking through the limitations of the original customer base and cooperating with external designers. Establish and activate the ecosystem within the word-making industry circle.

▲Font products produced by AI value-added character creation process: Wending cloud platform font management tool

General Manager Wu Fusheng of Wending Technology said: The Industrial Bureau has guided and participated in the AI value-added plan to demonstrate the empirical results. It has continued to invest 6 million every year since 2019, and has invested a total of 30 million in AI technology research and development by 2023. Wending plans The next stage will be transformed into a "smart font design service platform" and the iFontCloud font library will be opened to all people who love words. Everyone can create personal style fonts through the platform and can be applied in various fields. It is expected that will create greater business opportunities.

▲The font products produced by the iFontCloud-AI value-added character creation process are sold on the Wending cloud platform

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」