【2020 Application Example】 With the "fish product distribution robot", market price prediction, accurate distribution, automated supply chain reporting, and AI customer service are all available!

The freshness and quality of ocean fishery products affect sales

Edible deep-sea fish such as salmon, squid, pomfret, and white pomfret are favorite fish species of the Chinese people. According to the 2018 Fishery Statistics Annual Report, the output value of offshore fisheries is as high as 35.7 billion yuan, accounting for 10% of Taiwan’s fishery industry. The total output value is nearly 40%! The main importing places for Taiwan’s distant-water fisheries are Norway, Scotland, Sri Lanka, Canada, Australia, India, New Zealand, Maldives and other places. Part of the triangular trade is imported from the Middle East, India, Norway, and Sri Lanka, and then frozen and chilled sharks are re-exported to mainland China.

The fish products of a domestic fishery product import trader mainly consist of chilled fish products, which are characterized by freshness and good quality. Therefore, the fish products are all shipped to Taiwan by air. After customs clearance at the airport, they are directly handed over to the freight forwarder. The operator distributes to agents or distributors in major wholesale fish markets across Taiwan. Therefore, the ability to accurately predict the transaction prices of each fishing market and the sales volume of agents every day has become the key to making a profit that day!

There is currently no effective way to predict the price of fishery products the next day

There are two ways for importers of fishery products to sell fish to wholesalers. One is "consignment sales": it is mainly based on commission. After the agent deducts necessary fees and commissions from the payment received from the sale, The balance is fully delivered to the traders; the second is "goods selling": the fish products are sold directly to downstream dealers. Among the two, the consignment method is the largest. After the consignment sells the fish, the consignment will return the selling price to the company on the same day. The business owner will collect payment from the consignment regularly after deducting commissions from the reported selling price.

Therefore, whether different fish products can be sent to relatively high-priced fish markets for sale every day has become the key to whether the day is profitable; however, this key factor depends on whether the transaction prices of each fish market can be accurately predicted and Reseller sales. However, as climate change causes ocean temperatures to warm and catches become difficult to estimate, price fluctuations in local fishing markets are less manageable than in the past.

Currently, there is no effective way to predict the price of fishery products the next day. Shipping decisions are all made by staff based on rules of thumb. It is difficult to grasp the profit factors. We can only depend on the fate of God and market prices. There is a risk of loss every day. .

Intelligent price prediction-a tool for fishing trade

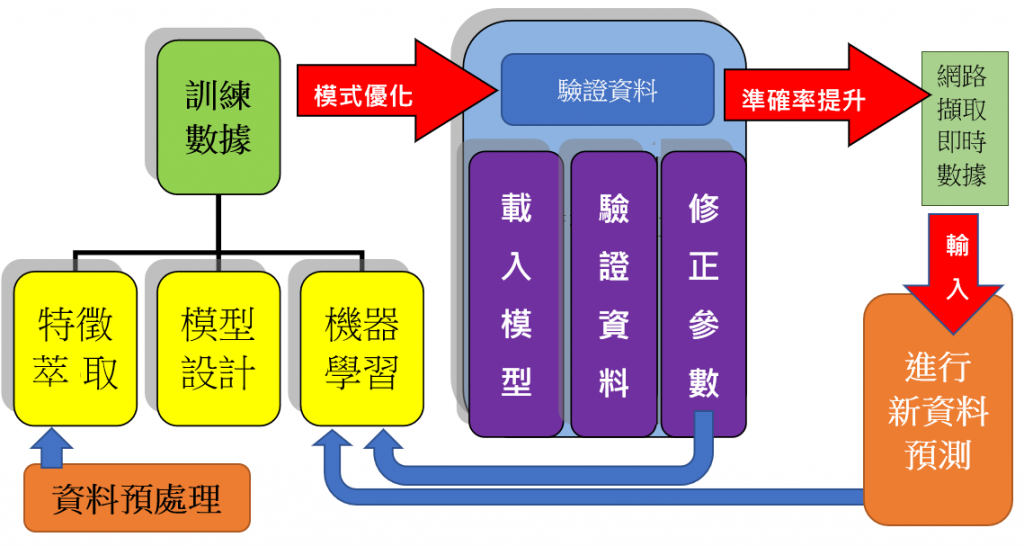

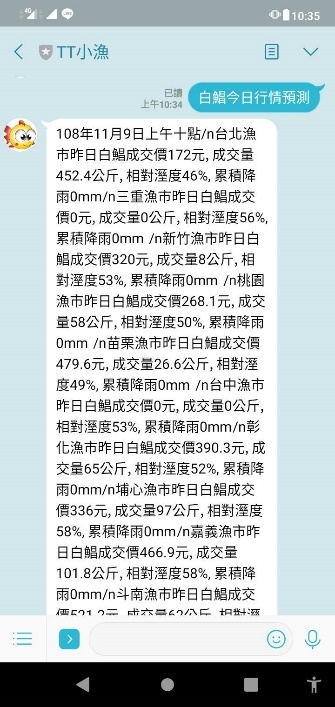

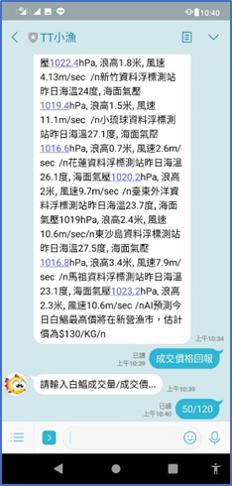

Weiying Information Technology Co., Ltd. uses a web crawler program to automatically extract the price and volume information of each fishing market in Taiwan on trading days and the climate data recorded by the local climate observatory, and then uses the neural network to match the machine Learn the model established to predict the trading price of fishery products the next day. Modeling with climate data.

▲AI intelligent price prediction model operation process

The transaction prices of fishery products come from the "Fishery Products Global Information Network". Its website records the price and volume information of various fishing markets in Taiwan on trading days. Climatic data is obtained from the "Observation Data Query System", including precipitation, wind direction, wind speed, air pressure and other index values. The above two websites are open data established by the public sector, and the data volume is sufficient, detailed and stable.

This "AI smart price prediction model" targets Keelung Fishing Market, which accounts for the largest sales volume. It combines climate data and fishery market data as the "input variables" of the model, and the "predicted variables" output by the model are each The trading prices of fish species on the day; the data on the day that still have missing values in the data are eliminated, and divided into a training set and a test set at a ratio of 8:2 for model training. Based on the forecast data, algorithms are used to determine the best distribution combination, and Line BOT voice robots are used to communicate with consignors about the fish items, specifications and quantities they require. Robotic process automation (RPA) is used to streamline manpower and improve efficiency.

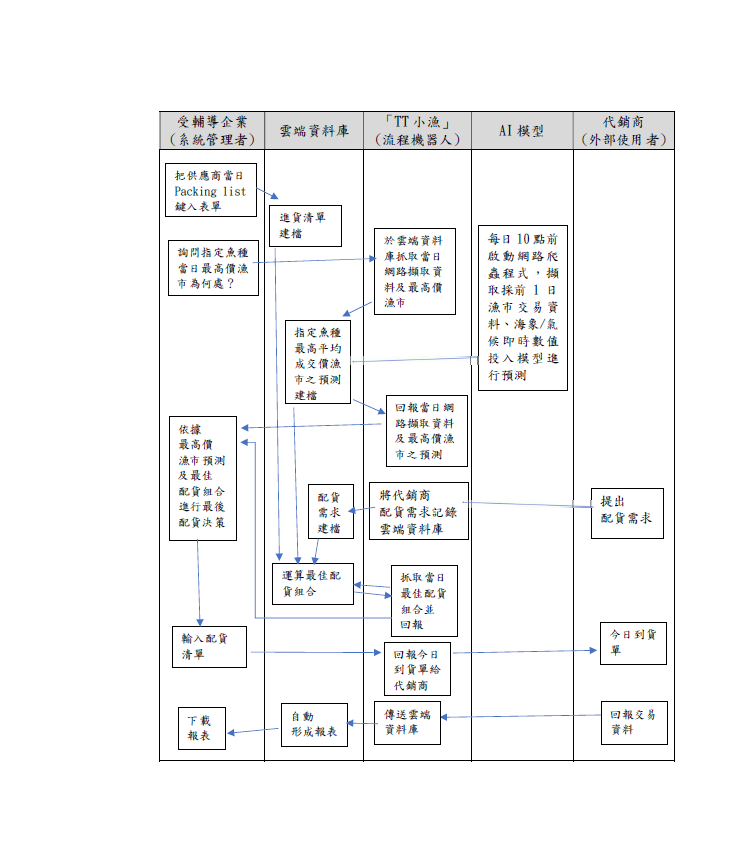

▲AI intelligent price prediction system operation process

"AI intelligent price prediction model" effectively increases sales gross profit margin, and future business opportunities are just around the corner!

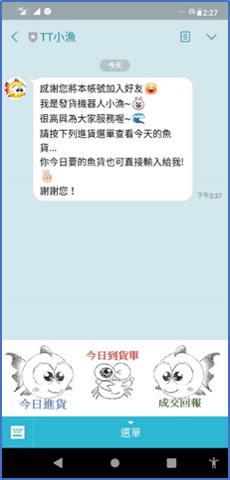

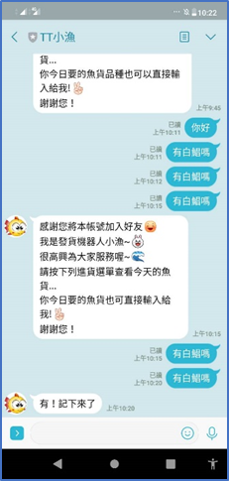

Traders import AI robots into the enterprise process system, and then use algorithms to determine the best distribution combination based on forecast data. They contact distributors through the Line bot voice robot to complete distribution decisions and information transmission, streamlining manpower. and increase gross sales profit margin.

▲Contact resellers through Line chatbot 1

▲Contact resellers through Line chatbot 4

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」