【2020 Application Example】 AI Silver Care Smart Platform

As Taiwan's elderly population gradually grows, more and more people require long-term care, but the supply side is never enough to support such a huge demand. In the past, a total of 110,000 caregivers were trained, but currently only about 20,000 are actually engaged in care work. According to estimates from the Ministry of Health and Welfare, long-term care 2.0 will require more than 30,000 care workers, indicating that there is still a large manpower gap to be filled. In addition, the turnover rate of nursing staff is also extremely high, which makes the situation even worse. This dilemma has caused the elderly who should have received proper differentiated care to be unable to be properly taken care of. In addition, it has also caused institutional operators to spend huge time costs on education and training, thus reducing the quality of care.

AI Silver Care Smart Platform

(1) Basic hospital management: basic settings, equipment settings, hospital authority role settings, staff management, face recognition, resident role management, fall risk assessment, and bedsore risk assessment.

(2) Bed management: bed management and bed status.

(3) Resident management: resident information (basic information, bed records, face recognition forms), resident case closure information.

(4) Message record: face recognition record, fall message record, electronic fence message record and blood glucose machine remote measurement result record.

On the upper right side are matters that need to be reminded of residents, such as quarterly assessments, new residents within 72 hours, care plans, rehabilitation plans, treatment plans and nutritional assessment plan personnel. The lower right is the resident search list and the newly added new resident block. The right is the assessment service plan reminder. Click to check which residents need to arrange time for the plan.

Machine and equipment settings: If new machines and equipment in the hospital need to be added, such as face recognition lenses, after clicking on the new device in the upper right corner, the corresponding device ID, field name, IP location, and device type can be set. After entering the status, account and password, the connection settings between the machine and the corresponding field can be completed.

▲Machine and Equipment Settings

Permission settings: Add a permission button in the upper right corner. After clicking it, you can add a permission role and check the CHECKBOX corresponding to each major function. This function corresponds to hospital staff management, and you can create new hospital staff corresponding to permission roles. , in this way, the member's login account password will have member-exclusive functions appear in the left menu, achieving the purpose of authority control personnel.

▲Permission settings

Bed Management: After clicking the Add Bed button, you can enter the corresponding field name (such as which building, regional classification name), dormitory name (A01) and bed number (01~06) fields, all beds in the hospital After the construction is completed, the beds will be available for residents to choose from.

▲Bed Management

Bed status: You can check whether the current bed is corresponding to the resident. If it is corresponding, you can also use the hospital bed to query the corresponding resident information. After clicking on the bed history record query, you can query the historical information of all beds occupied.

▲Bed status

Resident information list: When a new resident moves in, he or she can click the Add Resident button on the homepage to enter this page. After clicking the Add button, it will be divided into four major categories: basic information, emergency contact person, personal living conditions, and imported finances. to fill it in. After completion, press the save button to return to the resident list. Find the newly added resident and click on the case medical record function. In addition to the basic information above, there are four items of information that need to be completed for individual residents, such as resident photos and attachments. Information, meeting minutes and evaluation records.

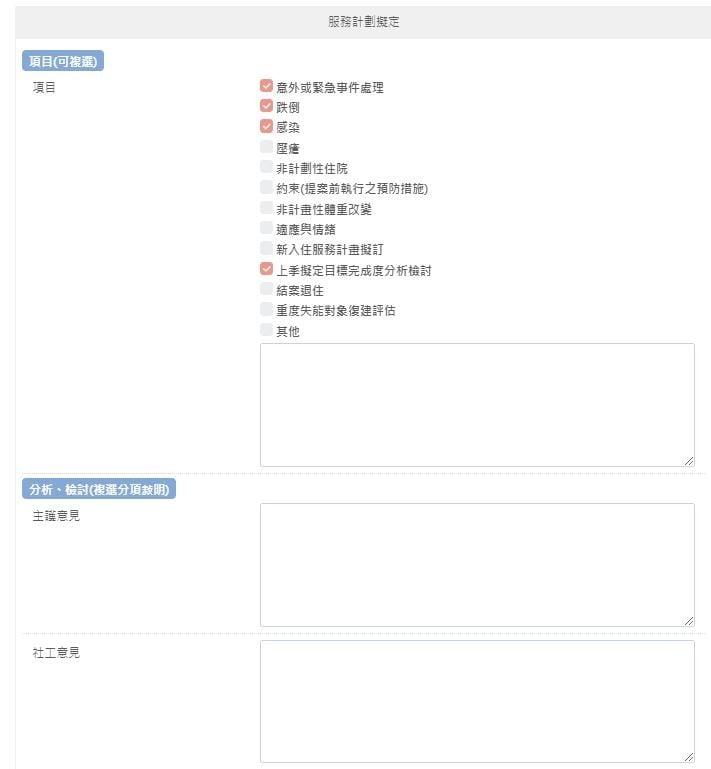

You can upload three photos of residents, which can be used for face recognition and homepage profile pictures. The documents to be attached include a copy of the ID card, a household register or a copy of the household registration, a family tree, an ecological map, a low- and middle-income certificate, a disability handbook, a subsidy letter, photos of financial items, and other items. Minutes of the meeting are taken to assess the completion of the service plan items to be carried out. The evaluation form is to understand the residents in more detail. The information and analysis items need to be filled in. The system will draw conclusions based on the item analysis and provide the nurse with reference for the care plan.

▲Basic information on residents

Information attached to the Resident Inspection:

▲Residential Inspection Attached Information

Fall assessment for new residents: One of the items in the assessment form is fall risk factor assessment. Fill in the questions in the field below, and the system will give a score to determine whether there is a risk assessment judgment. This is the current organization's early assessment of fall risk. Prevention mechanism

< /figure>

< /figure>

▲Service plan generated 1

▲Service plan generation 2

Smart reminder function: There is a reminder function in the lower right block of the homepage. For each resident every month or quarter, after calculation by the system, it will automatically remind nursing or social workers to fill in the form and complete the work required by the resident. .

< /figure>

< /figure>

▲Smart Reminder Entrance

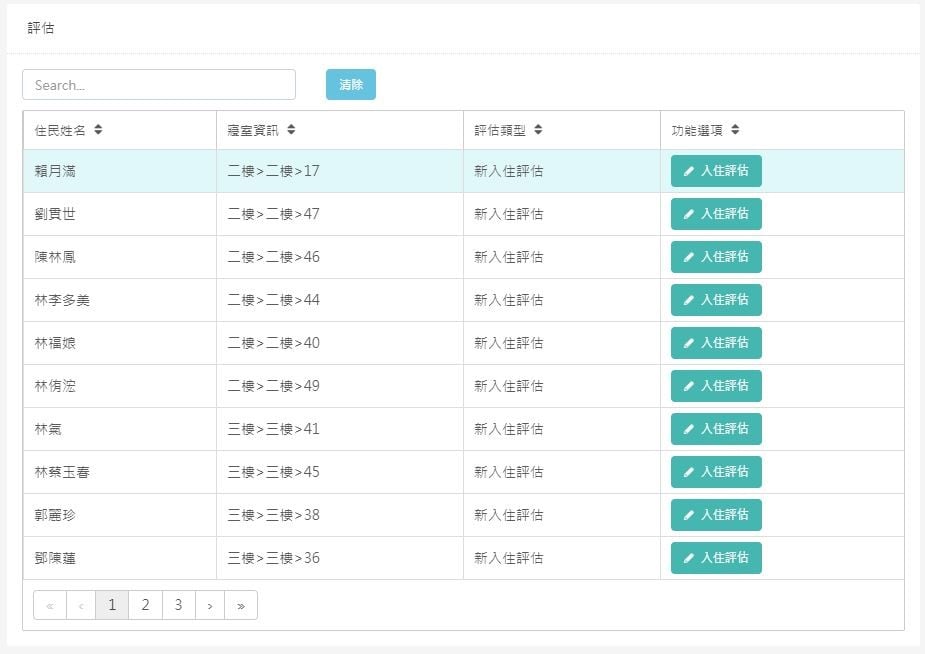

Click on the check-in assessment link to enter the list of residents who need to fill in the information. Agency staff then fill in the information according to their nursing or social worker status. After completion, the reminder for the residents will disappear and the reminder message will appear again next month.

< /figure>

< /figure>

▲Remind evaluation service records

The system will also automatically remind you to evaluate the service records every week. After the caregivers complete the care plan, they must make a relevant record sheet every week to check whether each service is consistent.

Smart evaluation function: After selecting the residents to be queried, click the evaluation function to enter the evaluation query list.

▲Evaluation Query List

▲Evaluation Record

Click on the evaluation plan query to retrieve all previously recorded data from the system for evaluation use.

The query records filled in each form will be displayed on the following page in sequence according to the sub-functions.

Since the AI function of fall and pressure ulcer risk assessment is based on 11 physiological data, the service can be spread to the elderly outside long-term care residential institutions, such as the elderly in day care services and the elderly in home services. By. It is expected that next year it will be extended to the elderly in day care institutions and the elderly in need of home services.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」