【2021 Solutions】 Industry-university cooperation shows results. National Taiwan University of Science and Technology’s Artificial Intelligence Operations Management Research Center uses AI to assist enterprises in digital transformation.

In intelligent systems, AI plays a key role. In addition to cultivating professional AI talents, the Artificial Intelligence Operations Management Research Center of the National Taiwan University of Science and Technology also actively conducts various project studies with enterprises to accelerate the implementation of industrial intelligence in Taiwan. One of the cases uses artificial intelligence and machine learning methods to use quality information for maintenance prediction and planning, which greatly improves equipment reliability and product quality. Using quality defect detection AOI technology can reduce the rate of missed defects.

Yu Wenhuang, director of the Artificial Intelligence Operations Management Research Center of the National Taiwan University of Science and Technology, observed that industry demand for AI is increasingly strong, and electronic manufacturing, finance, medical and other fields have greater development potential. On the one hand, the above-mentioned industries have a high degree of informatization, and automation products Online technology and the digital environment are mature and have the conditions for the development of AI technology; on the other hand, because the data required by the industrial environment has been retained, managed and used, it is easier to promote the application and solutions of AI technology when the concepts and data are available plan.

Quality defect detection AOI technology effectively reduces the wrong kill rate

For example, in the field of smart manufacturing, the team of the National Taiwan University of Science and Technology's Artificial Intelligence Operations Management Research Center assisted Taiwan's major electronics manufacturers in constructing a production line equipment diagnostic system and building a sensing network architecture in the production line equipment at the manufacturing site to detect Measure and record the operating status of the machine. Through big data analysis, a warning can be issued when an abnormality occurs on the machine to remind the manager to schedule maintenance. We use the AOI quality defect detection process, combined with machine vision and deep learning technology, to detect defects in electronic parts and perform real-time control and monitoring to assist companies in developing automated optical inspection stations, surface defect algorithms, and management application functional services.

In the flexible printed circuit board (FPC) industry, quality defect detection technology is used for image identification, mainly for re-inspection after the initial inspection, and the original inspection results are designed to be re-inspected. When doing defect detection, ordinary factories often believe that "they would rather kill a hundred by mistake than let one go" and adopt the most stringent testing standards. With the current testing technology and process, it may cause excessive detection and waste the cost of good products. .

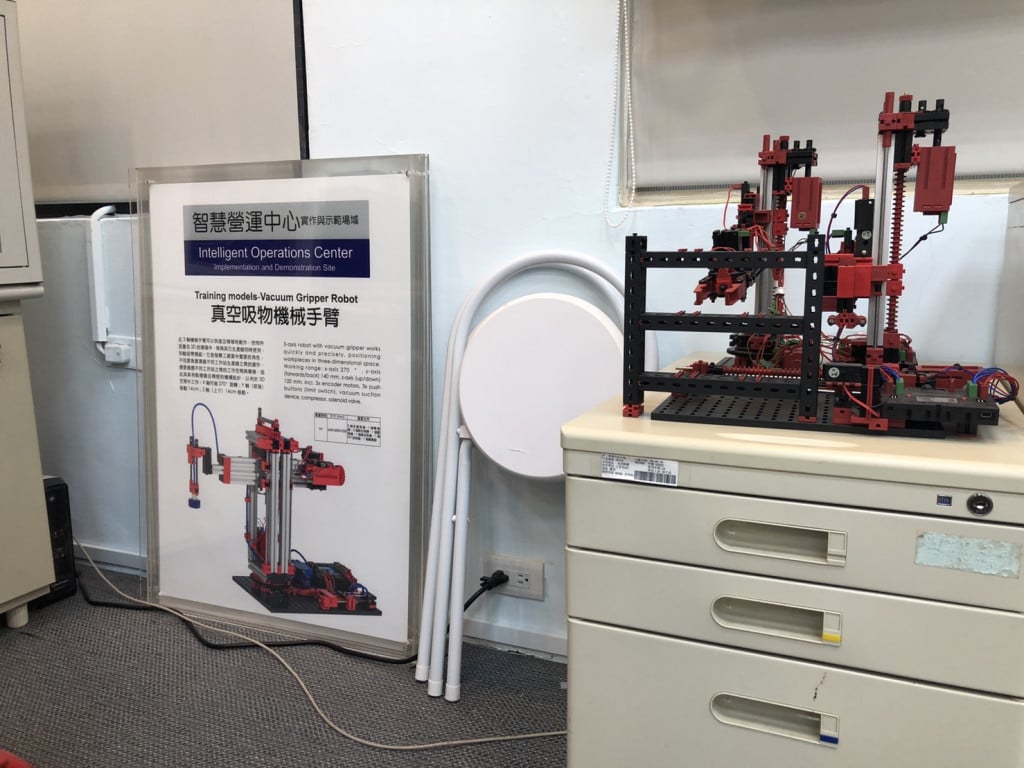

▲The Artificial Intelligence Operations Management Research Center of National Taiwan University of Science and Technology focuses on smart manufacturing solutions.

Lecturer Professor Cao Yuzhong, director of the National Taiwan University of Science and Technology Artificial Intelligence Operations Management Research Center, said that the current flaw detection, AI model and algorithm construction and training of the National Taiwan University of Science and Technology Artificial Intelligence Operations Management Research Center have achieved preliminary results. The center hopes to use images to The results of the identification can help companies quickly identify defects and quality status of products during the production process. After that, the next stage can start from the source, how to optimize parameters, improve behavior in the production process, and assist the factory to optimize the process. Better. During the product production process, the parameters of the machine equipment can be used to analyze machine data abnormalities and summarize different patterns for future maintenance and quality management to provide reference for enterprises in the application field.

The epidemic is the biggest catalyst for digital transformation for enterprises. Director Cao pointed out that the introduction of AI to promote digital transformation of enterprises is not necessarily just based on reducing costs or improving production efficiency, but must be based on the fundamental development goals and the essence of the problem. Process analysis, thinking about how to use AI or ICT technology to serve and meet process and customer needs. This process often requires breaking out of the existing framework to help companies reshape new operations and management models to effectively improve corporate performance.

The biggest challenge for enterprises introducing AI: improving customer trust

In the process of expanding AI industry-university cooperation, Yu Wenhuang believes that the biggest challenge is to enhance the trust of enterprises in you. For customers, a certain degree of trust is required before the Know-How of the production line can be communicated to you. Share and tell you where the focus of business is. In the absence of business trust, it is difficult for AI industry players to analyze the availability of processes and data. Enterprises usually consider two key points when choosing AI cooperation partners:

1. When cooperating with you, will the data and results be sold to others?

2. Will the cost of customization be too high? Although companies are less wary of academia, Director Yu still believes that gaining customer trust and jointly establishing sustainable AI innovation application capabilities and development goals are the key to The key factors for all ICT companies to face industrial customers and their ability to provide AI solutions.

Regarding the cultivation of AI talents, Yu Wenhuang also has his own unique insights. He observed that the education system from junior high schools, high schools to universities has driven the trend of AI. However, AI technology itself has many theoretical foundations and industrial knowledge that must be integrated. When talking about AI talent cultivation, we should first define how to construct a talent development system or route in the AI field, what types of people are needed to introduce AI into the economic system, systematize talent positioning and characteristics, and let talents who are interested in investing in the AI industry understand how to use their own The goal measures the types of AI skills and jobs that can be developed.

Secondly, it is to help companies that want to promote AI in a systematic way to understand, whether it is developing applications or building technical teams, how to measure the talent needs and technical blueprint corresponding to business goals. It not only plays the role of problem-solving, because AI It is just one of the ways to solve the problem. Only by assisting enterprises to establish innovative consciousness with AI R&D thinking can we truly implement industrial development, strengthen demand and promote both supply and demand at the same time, and accelerate the implementation of AI applications and talent cultivation.

NTUST Artificial Intelligence Operations Management Center provides a number of smart manufacturing solutions

Regarding smart manufacturing solutions, the solutions provided by the Artificial Intelligence Operations Management Center of National Taiwan University of Science and Technology are as follows:

. Intelligent predictive maintenance

Adopting artificial intelligence and machine learning methods, using quality information for maintenance prediction and planning, greatly improving equipment reliability and product quality, establishing failure modes and reliability analysis based on different equipment operating characteristics, and using process control analysis to trace products Quality history helps on-site personnel eliminate operational abnormalities in a timely manner.

. Smart dispatch and scheduling planning

According to the characteristics of the industry, develop intelligent labor dispatch and scheduling algorithms to effectively shorten setup time and total working hours. For example, for a variety of workpieces, the production schedule must meet conditions such as combined material preparation, group production, and specific process sequences. From the group production of workpieces, the assignment of adapted production lines, to the multi-parallel single-machine scheduling that adjusts the production sequence of each production line under grouping, the optimization algorithm is introduced to design a complete smart schedule. system.

. Deep learning and automatic optical inspection

Improve quality defect detection AOI technology, using machine vision and deep learning, which can detect flat and curved surfaces of metal electronic parts, and perform real-time control and monitoring, including automated optical inspection stations, metal AOI defect algorithms, and modular design and other application technologies.

The design elements of this algorithm: 1. Automated optical inspection station 2. Metal AOI defect algorithm 3. Modular design

. Smart Situation Room

Combined with high-end graphics card flexible assembly units, including processing machines, industrial robot arms, collaborative robot arms, engineering inspection stations and conveyor belts, a smart war room with digital twin technology is established. The technical features include real-time monitoring, data integration, data Transparency and data visibility.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」