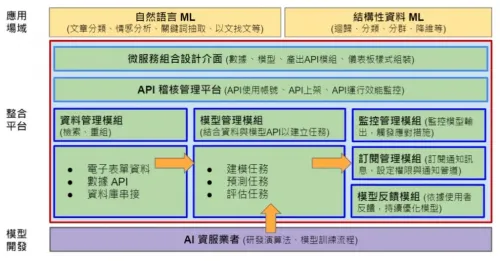

【2020 Application Example】 AI Implementation in Construction Industry Reduces Workplace Accidents: Safety Visibility Enhanced

The construction industry is Taiwan's leading industry, supporting the architecture, decoration, and repair sectors. However, the high incidence of occupational accidents in this sector is a major concern for both employers and workers. The introduction of AI for equipment recognition in the construction industry reassures companies and protects workers, creating a win-win situation.

According to the Ministry of Labor's 2017 statistics on occupational injuries, the average rate of occupational injuries per thousand workers across various industries is 2.773. However, the construction industry tops the list with a rate of 10.036, which is 3.6 times the average and categorizes it as a high-risk group for occupational injuries. Proactive early warning measures can significantly reduce the rate of workplace accidents.

In light of this, the Institute for Information Industry, under the mandate of the Ministry of Economic Affairs' Industrial Development Bureau, has initiated an AI project that prioritizes the implementation of AI technology in the construction industry. Selecting well-known construction firms in Taiwan, the project applies Canon's safety helmet proper wearing recognition solution to reduce occupational accident rates.

Smart Recognition of Safety Helmet Wearing: A Solution for Employers

Senior executives in the construction industry emphasize that compared to other industries, construction workers face higher health and safety risks primarily at construction sites. Many risks arise from the workers not properly wearing or using personal protective equipment, such as safety helmets. Relying solely on human supervision for ensuring safety gear compliance is time-consuming and often ineffective. Implementing AI technology for smart monitoring on construction sites can save corporate resources while ensuring worker safety, achieving dual benefits.

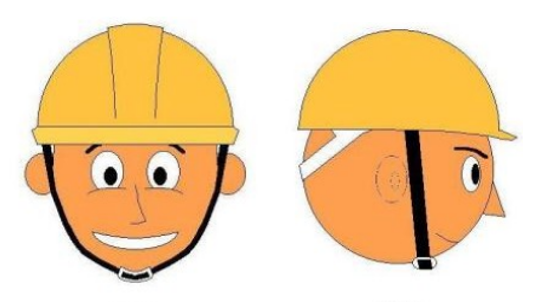

Indeed, to protect workers during operations, construction plants require workers to properly wear safety helmets. Wearing a helmet does not imply it is worn correctly. To prevent the helmet from falling off during operations, it is necessary to securely fasten the chin strap directly under the chin after putting on the helmet.

▲工地用安全帽正確佩戴方法

At construction sites, many foreign workers often do not follow proper safety protocols, such as not wearing safety helmets correctly. If supervisory personnel were to be assigned, it would entail excessive use of human resources. With the assistance of the information strategy team, major construction companies have adopted Canon's image recognition technology.

To determine the optimal placement of image recognition cameras, both teams first conduct site surveys and collect various types of safety helmets used on-site. Subsequently, standard cameras are installed at entry points of construction sites and work zones to capture footage of the site personnel. This footage helps Canon develop models for correctly and incorrectly worn helmets, aiding the image recognition software in its learning phase. Canon's engineers regularly visit the site to retrieve footage, and once the image recognition software achieves a certain accuracy level, the image recognition cameras are then installed at the construction site.

1.png)

▲佳能工地安全帽資料搜集攝影機設置

Improving Recognition Accuracy for Concrete Implementation of Workplace Safety

Currently, no local technology can accurately recognize the proper wearing of safety helmets. Therefore, Canon has developed and trained its own recognition software. The complex environment at the actual installation sites can impact the effectiveness of recognition.

In the future, machine learning will significantly enhance the overall recognition accuracy, ensuring that safety measures involving the wearing of safety helmets are concretely implemented.

While AI recognition technology is introduced in the construction industry's safety domain, it can also be integrated with mobile devices for early warning. In practice, once a camera captures recognition data and processes it, the results can be pushed immediately to specific individuals such as safety managers on their mobile phones, tablets, or even linked to access control systems. If a worker is detected without a properly worn safety helmet, relevant personnel can be alerted promptly. Access can be denied until the worker correctly wears the safety helmet, offering considerable potential for future applications.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」