【2022 Solutions】 Utilizing Extreme Present Tech's 4D Drone Cloud Platform Reduces Inspection Costs to One-Fifth

The use of drones for intelligent inspection is becoming increasingly common, with major petrochemical and solar power plants continuing to adopt drone applications. Located in Hsinchu, Extreme Present Technology (earthbook) has established a 4D cloud platform using its proprietary technology, offering drone, software, and data analysis platform services for intelligent inspections at solar power and petrochemical plants, reducing the total cost to just one-fifth of traditional methods involving hardware and software purchases, and cutting down the time from one month to approximately 24 hours, making it highly cost-effective.

For petrochemical industry operators who are constantly in a high-temperature, high-pressure dangerous environment, the safety control and inspection of plant facilities are critical. 'As long as we can enhance the capabilities of facility inspection and risk identification in petrochemical sites, resource input is absolutely not an issue,' said a petrochemical industry representative with emphasis. By implementing the drone 4D AI inspection cloud platform, the efficiency and safety of facility inspections among petrochemical operators can be elevated, further reducing the risk of equipment downtime.

Founded in March 2018, Extreme Present Tech has become a consistent winner in domestic entrepreneurship competitions, including being crowned champion in the 2019 OPEN DATA Business Innovation Practice, selected into Microsoft's startup accelerator in 2020, chosen for NVIDIA's AI startup team in 2021, and its products have been launched on the Microsoft Azure platform, earning investments from the National Development Fund and major domestic groups, thereby securing strong market validation for its technical prowess and services.

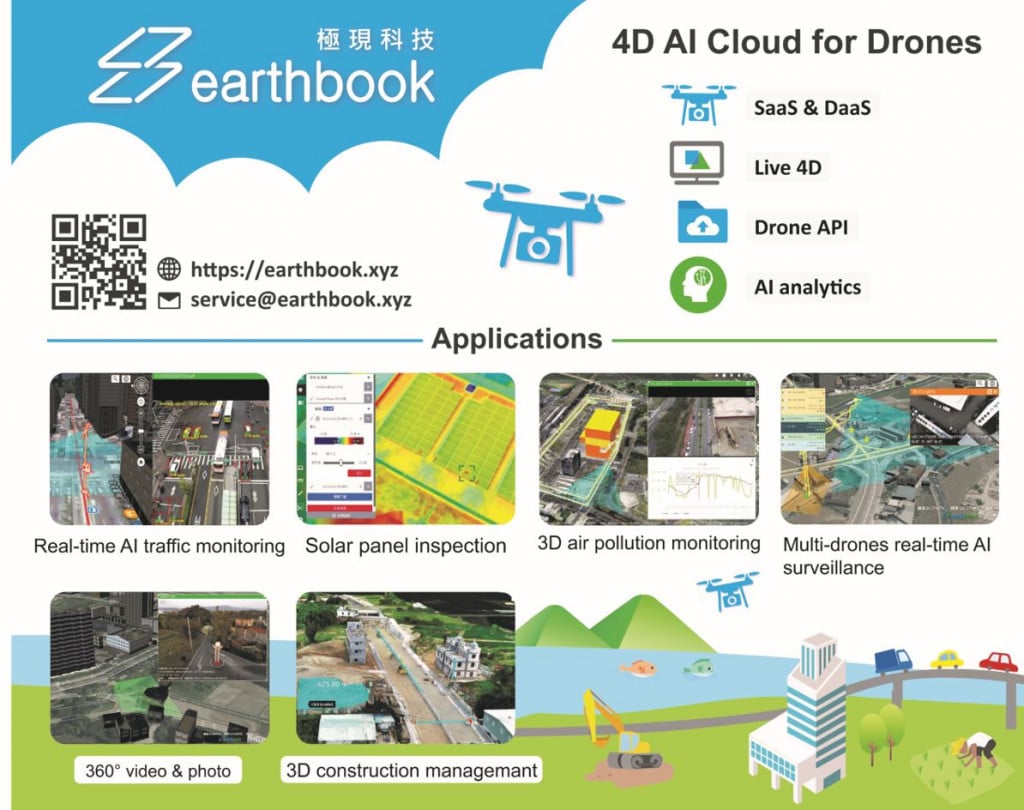

The founder and CEO of Extreme Present Tech, Hsu Wei-Cheng, mentioned that at the beginning of its establishment, the company took on the national space center's satellite 3D photography scheduling system and specialized in the integration of geographic information into 3D images. As drone hardware technologies matured, the company shifted its operations towards the drone market and combined it with AI image recognition systems to establish a 4D cloud DaaS platform, offering services including online aerial photography ordering (DaaS), 5GAIoT cloud platform (SaaS), and enterprise+API server software, to meet the demands of drones in smart cities, facility inspection, engineering management, disaster response, pollution monitoring, and other applications, maximizing the value of drone services.

Smart aerial inspection regularly tracks the health status of plant equipment at a glance.

The quantity and area of petrochemical plants in Taiwan are immense, lacking sufficient manpower for comprehensive equipment inspections. Given that petrochemical plants produce high-temperature flammable and corrosive chemicals that must be transmitted and stored through pipelines and tanks, long-term risks like pipeline ruptures and tank blockages could lead to severe occupational safety disasters, equipment downtime, and production stagnation.

Given the shortfalls in personnel for equipment inspections among petrochemical operators, Extreme Tech has already implemented a 4D AI drone inspection cloud platform combined with AI image recognition technology in petrochemical plant areas, providing ground-breaking evidence through the use of drones and proprietary app software services that connect on-site aerial data collection to the cloud platform, achieving fully automated and real-time aerial monitoring of petrochemical plant equipment (pipelines, tanks), and ensuring precise locations and angles for each aerial operation, effectively compensating for the discrepancy in human inspection.

Hsu Wei-Cheng pointed out that the inspection drones used in petrochemical plants are equipped with dual lenses, one visible light and the other thermal infrared, which allow for determining pipeline obstructions through temperature conditions, enabling clients to immediately view the inspection status of the plant area from remote locations via the earthbook website, enhancing clients' inspection efficiency and accuracy.

▲The 4D aerial data platform meets diverse applications such as smart cities, transportation, engineering management, and pollution monitoring.

DaaS Online Order-Use Model Innovates Aerial Photography Business Model Saving 1/5 Costs

Apart from providing a 4D aerial data platform, Extreme Present Tech also offers DaaS (Drone as a Service). After customers place orders on the website, Extreme Present coordinates with professionally licensed aerial photographers to provide on-site services. Customers can monitor real-time operations through the platform and quickly obtain aerial data to evaluate any abnormalities, enabling timely alerts.

Take the solar power plant monitoring service as an example. Given that solar power plant areas are large and widely distributed, located in the remote Pingtung area with the headquarters in Taipei, for inspections of the Pingtung plant, the customer just needs to use the DaaS service model, directly order online and upload a map of the Pingtung plant, obtain a quote from the company, and then entrust local Pingtung pilots to perform aerial inspections of the solar power plant. During the process, the drone's route is automatically calculated by AI to plan the flight path, and the aerial data is transmitted to the client's cloud account, allowing the Taipei headquarters clients to immediately see the inspection status of the solar power plant from the earthbook website such as the condition of the solar panels, dust detection, or abnormal heat generation from solar electromagnetism, effectively helping the customer significantly reduce operational costs and efficiently complete the solar power plant inspection service.

▲Introduction of DaaS online aerial photography service in petrochemical plants.

According to estimates, solar power plant clients often incur high personnel costs by purchasing drones or outsourcing aerial photography. With the long-term provision of aerial photography devices and the DaaS business model by Extreme Present Tech, customers can save 4/5 of aerial photography costs, and obtain aerial inspection reports within 24 hours post-operation, helping clients efficiently identify issues with solar panels.

Aiming to become the largest aerial data service company and enter the Southeast Asian market

Since its establishment in 2018, Extreme Present Tech has rapidly grown in the aerial photography market with innovative thinking, actively expanding its aerial data application services. Currently focused on cultivating the Taiwan market, the company aims to enter Southeast Asian nations, with Indonesia chosen as the first stop due to its high demand for infrastructure. Hsu Wei-Cheng hopes that earthbook becomes the world's largest aerial data service platform. Besides completing the initial round of funding from the National Development Fund and major groups, to penetrate the international market, the company continuously improves its drone data services and AI technology innovations, while also requiring the assistance of entities like the Industrial Technology Research Institute to find strategic investors that complement the company, fulfilling its goal of becoming an international aerial data corporation in phases.

.jpg)

▲Founder and CEO of Extreme Present Tech, Hsu Wei-Cheng

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」