【2022 Application Example】 Taking advantage of green energy business opportunities, Hua Molybdenum Industry creates all-vanadium redox flow battery energy storage system equipment, the best choice for long-term energy storage

Green energy is the future trend and will surely lead to huge business opportunities in the future. Wind power has been one of the green energy sources that have attracted global attention in recent years. It will become an important force in my country's renewable energy and help Taiwan's power generation reach the goal of 20% by 2025 to improve Taiwan's energy independence. As the number and power of domestic wind turbines (wind turbines) increases year by year, it is particularly important to ensure that the power storage equipment achieves safe, long-term performance, is not easily attenuated during charging and discharging, and is sustainable, low-carbon and environmentally friendly. At the same time, the wind turbine equipment itself Health inspection, maintenance and repair have also become the focus of wind farm operators. In order to meet the needs of wind farm customers, the green energy business unit of Hua Mo Industry has launched long-lasting energy storage all-vanadium redox flow battery electrolyte and wind turbine AI predictive operation and maintenance, providing 100% safety, long-term efficiency and reducing customer initial manufacturing costs. cost-effective power energy storage equipment, and through AI predictive operation and maintenance services to help customers reduce power generation costs by 10% and save up to 30% in maintenance and warranty costs.

Hua Molybdenum Industry was established in 1998. The industry started by refining vanadium, molybdenum and rare metal elements and other products, and used them in high-end steel, professional chemicals and specialty chemicals industries, and vanadium is more like a steel-making Vitamins can increase the effectiveness of steelmaking. Among them, vanadium and molybdenum related products are one of the company's main projects. The company sees that the all-vanadium redox flow battery, which is 100% vanadium-based, will be a very promising mainstream green energy technology in terms of long-term energy storage in the future, and before 2010 The government has actively invited legal entities such as the Industrial Research Institute to conduct research on related component materials in solid-state batteries and all-vanadium batteries. In addition, the Ministry of Economic Affairs expects renewable energy to account for 20% of power generation in 2025 and reach 1.5GW. Based on the above Considering this, Hua Molybdenum Industry decided to devote all its efforts to research and invest in the technological development of self-developed all-vanadium redox flow battery electrolyte in 2017, in order to accelerate the compliance rate of renewable energy in 2025.

Hua Molybdenum pointed out that "renewable energy power is relatively unstable, and Taiwan itself lacks lithium resources. In lithium battery manufacturing, almost 80%-90% of battery cells must rely on foreign procurement, and there is a lack of 100% domestic self-sufficient energy storage. Resources and technology. "Similarly, how does Taiwan overcome the problem of having no natural vanadium resources? To this end, Hua Molybdenum Industry uses original technology to use waste catalysts from petrochemical industries such as CNPC refineries or Taishuo petrochemical processes. Up to 10% of the vanadium ion content can be used to extract high-value vanadium resources, thereby producing Taiwan's 100% self-made all-vanadium redox flow battery electrolyte without being affected by resources, effectively achieving resource recycling. Since 2017, Hua Molybdenum Industrial has successfully created all-vanadium flow electrolyte technology, and has successfully passed product verification by the Industrial Research Institute, the Nuclear Research Institute and many international manufacturers.

Taiwan’s power storage energy target is to reach 1.5GW in 2025. Its power distribution includes 500MW in Taipower’s automatic frequency regulation system, 500MW in E-dReg and 500MW in existing or newly built solar power plants. For example, electricity consumption is mainly between 4 pm and 10 pm, which is the peak period for people's daily electricity consumption. For this reason, the Energy Administration specifically requires Taipower to strengthen the upgrade of energy storage equipment, which has also driven the market's interest in all-vanadium redox flow batteries. Energy storage system equipment is in high demand. In addition, Taiwan's current total power reserve construction and contribution has not yet reached 100MW, and the gap from the 2025 target of 1.5GW of power storage is still more than 15 times.

Using all-vanadium redox flow batteries to successfully create 100% safe, low-carbon, environmentally friendly and long-lasting energy storage system equipment

Compared with the short-term power storage of lithium batteries, the biggest advantage of all-vanadium redox flow batteries is that it is globally recognized as a long-term power reserve. It can store energy for a long time up to 12 hours, which means that if it is charged for 12 hours, It can release power for 12 hours. Compared with the electricity measurement method of general energy storage systems, which is daily electricity consumption = power (in kilowatts) x time (in hours), for all-vanadium redox flow batteries, power and hours are different. Special design, the power is also called a stack, which is composed of four materials: metal, polymer mold, carbon felt and graphite plate, and the power consumption time is calculated based on the amount of electrolyte (in cubes). Therefore, when the power (electric push) x the amount of electrolyte = the daily electricity consumption of our all-vanadium redox flow battery for energy storage.

The product features of the all-vanadium redox flow battery energy storage system equipment include four major features: safety, long-term performance, not easy to decay during charging and discharging, and sustainable, low-carbon and environmentally friendly. The quality of the all-vanadium flow battery is 100% safe. Since the electric energy is stored in the vanadium-containing electrolyte, it can avoid any flammable accidents caused by a fully charged energy storage system. In terms of battery life, compared to the short battery life of lithium batteries, all-vanadium redox flow batteries can have a battery life of more than 20-25 years through changes in price. Regarding the charge and discharge performance of energy storage, unlike lithium batteries which have a certain number of charge and discharge times (5000-600 times), there is no limit to the number of charge and discharge times of all-vanadium redox flow batteries. Regarding zero carbon emissions, which is highly valued globally, unlike lithium batteries which have recycling issues, the electrolyte of the all-vanadium redox flow battery can be used permanently. The material components of the stack are environmentally friendly and fully recyclable to create a truly sustainable and low-cost Carbon-friendly energy storage system.

Onshore wind turbine AI prediction smart operation and maintenance allows customers to reduce power generation costs by 10% and save maintenance and warranty costs by up to 30%

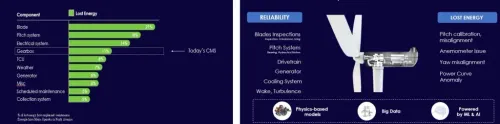

Hua Molybdenum Industry not only improves the long-term power storage efficiency of renewable energy customers through all-vanadium redox flow battery energy storage system equipment and helps customers reduce initial purchase costs, but also uses AI smart operation and maintenance empirical calculations for offshore and onshore wind turbines. Field demonstrations were drawn on Taipower's onshore wind farm, and we actively accumulated our own technical experience and energy in AI predictive operation and maintenance. With the support of the AI HUB project of the Industrial Bureau of the Ministry of Economic Affairs, the cooperation site will focus on the Phase I wind farm of Taipower Corporation and provide smart operation data of wind turbines for more than 6 months for analysis. The AI predictive operation and maintenance system for onshore wind turbines uses machine learning. The main technology provider comes from ONYX Insight, a subsidiary of British Petroleum (BP). The company uses AI Hub analysis software technology to analyze the wind turbines faced by Taipower. Pain point analysis, including power generation loss of road-based wind turbines and damage prediction of key components of land-based wind turbines (such as gearboxes, pitch bearings...) under abnormal vibration (three-dimensional vibration frequency) or abnormal temperature, etc. output. Through this implementation, it can effectively help Taipower reduce power generation costs by 10%, increase asset value by 1~2%, and save up to 30% in maintenance and warranty costs. In the past three years, ONYX Insight has successfully predicted and operated more than 20,000 offshore or onshore wind turbines around the world, accumulating extremely high AI model accuracy. It is believed that the international partnership established with ONYX Insight will effectively guide and accelerate the green energy division of Hua Molybdenum Industry in its goal and layout to become an independent technology service provider for wind turbine AI predictive operation and maintenance.

▲Works with partner ONYX insight to provide customers with an AI predictive operation and maintenance system, including wind turbine power generation loss and damage prediction of key wind turbine components

Building a solid foundation for domestic wind turbine operation and maintenance, using Taiwan as a base to expand to Southeast Asian wind farms

The market output value of offshore wind turbine AI predictive operation and maintenance in Taiwan will exceed NT$30 billion in the future, and the energy storage market has an output value of more than 100 billion US dollars globally. In the future company vision, Hua Molybdenum Industrial hopes to become An independent technical service provider for vanadium flow battery electrolyte and wind turbine AI predictive operation and maintenance. The long-term goal is to establish a local supply chain of vanadium flow battery electrolytes around the world by accumulating abundant technology and performance capital to supply industry needs nearby.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」