【2021 Application Example】 Massive Digital Engineering AOI Intelligent Robotic Arm Inspection System Significantly Improves Defect Detection Accuracy

Taiwan is known as a manufacturing powerhouse, yet quality defect detection has always been a chronic sore point in production lines. While AOI equipment is available to assist, most use fixed machinery which are limited by angles, resulting in less precise diagnostics and high false positive rates. Massive Digital Engineering introduced an AOI intelligent robotic arm detection system that effectively reduces false positives and increases the accuracy of defect detection.

Generally, the yield rate of products affects the costs for enterprises and the return rate for customers. The quality defect detection process in the manufacturing industry often necessitates a substantial amount of quality inspection labor. Although there is AOI equipment to assist, these tools are mostly fixed detection machines. Fixed cameras are easily limited by angles, resulting in less precise diagnostics and high false positive rates. Thus, personnel need to re-screen and inspect afterwards, often manually visual inspection misses defects on average about 5%, and can be as high as 20%.

Three major pain points in manufacturing quality detection: Robotic Arm + AOI with dynamic multi-angle inspection helps to solve these issues

According to the practical understanding by Massive Digital Engineering, there are three main pain points in detecting product quality within the manufacturing industry:

Pain point one, manual inspection of product quality is prone to errors. Currently, the manufacturing industry largely relies on human labor to inspect product appearance, but human judgment often entails errors, such as surface scratches, color differences, solder appearance, etc. The error rate in defect judgment is high, and can only be inspected at the finished product stage, often leading to whole batch rejections and high costs in labor and production.

Pain point two, inability to quantify and record data from quality inspections. Traditional manual inspections do not maintain inspection data, which makes it difficult to assign responsibility when quality disputes occur. Moreover, high-end contract manufacturing orders from overseas brands often require traceability and corresponding defect records, which traditional human inspection methods struggle to meet.

Pain point three, limitations of traditional AOI visual inspection systems. Current manufacturing uses AOI visual inspection systems, which due to the limitations of visual software technology, employ fixed cameras, fixed lighting, and single-angle operations. This method may handle flat or linear-shaped products (like rectangular or square items) at a single inspection point. However, it is more challenging to implement for products with complex shapes (e.g., irregular automotive parts), requiring multi-point and multi-degree inspections.

▲Massive Digital Engineering developed an AOI intelligent robotic arm detection system, effectively improving the accuracy of defect detection.

To address the pain points in quality inspection in manufacturing, Massive Digital Engineering initiated the concept of developing a multi-angle, movable inspection device, starting with the combination of two representative technologies in factory automation - robotic arms and machine vision. By integrating robotic arms with AOI for dynamic multi-angle AI real-time quality inspection, the limitations of fixed inspection systems are addressed, and visual inspection techniques are enhanced by leveraging artificial intelligence, further elevating the sampling of images from flat to multi-dimensional and multi-angular.

Selected the automotive industry as the real-world testing ground to quickly respond to customer needs

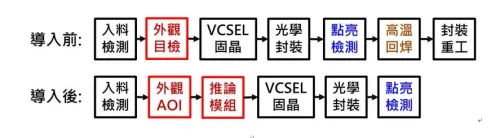

The AOI intelligent robotic arm detection system, utilizing AI technology including unsupervised learning, supervised learning, and semi-supervised learning, allows operators to use unsupervised deep learning techniques to learn about good products even when initial samples are incomplete or there are no defective samples, applying it in the visual inspection of automatic welding of car trusses. This can solve issues of limited angles with fixed machinery before implementation, less precise diagnostics, and high false positive rates.

▲Automotive components are high in unit price and demand a stricter defect detection accuracy.

In industries that have adopted AI services, the automotive manufacturing sector was chosen as the real-world testing ground. Massive Digital Engineering states that the automotive industry mainly consists of related component manufacturers and components typically have a higher unit price, hence requiring more in terms of quality inspection and yield rates, and demanding stricter accuracy. Therefore, the automotive sector was chosen as the area for introduction. By using a robotic arm combined with AI for dynamic multi-angle AOI visual real-time quality inspection, not only can the defect quality error rate of automotive components be improved, but the fixed-point AOI optical inspection can be enhanced to meet the measurement needs of most industries; and finally, establishing a third-party system platform to build an integrated monitoring system platform, enabling immediate response and action when issues arise.

This system allows for recording and storing important data of products leaving the factory, serving as a basis for future digital production lines and virtual production. At the same time, in the event of defects, it can immediately connect to Massive's MES monitoring system, quickly responding to the relevant manufacturing decision-making department, subsequently utilizing ERP systems for project management and reviews, effectively improving production efficiency and reducing production costs.

Helps to reduce communication costs and aims to become an industry standard

In terms of industry integration, it provides a foundational standard for data continuity among upstream and downstream businesses, reducing communication costs within the supply chain. Through certification of the contract manufacturers and brand owners, there is a chance to become the industry standard configuration. Through the data database established by this project, operators can further optimize their supply chain management solutions using big data analysis (Data Analysis), based on data, establish forecast planning, and utilizing technology to link upstream and downstream data of the supply chain, accurately controlling product quality. In the future, when interfacing with European, American, and Japanese markets, which demand highly fine-tuned orders, operators can respond and integrate the industry supply chain (Supply Chain) more swiftly.

Ultimately, through the benchmark demonstration industry's field verification, such as with the automotive component manufacturing industry used as the benchmark demonstration field, by implementing the robotic arm combined with AI for dynamic multi-angle AOI visual real-time quality inspection system project, the supply chain connection between automotive contract manufacturers and OEMs can be optimized, becoming the industry standard. Further seeking more AI teams to join the cross-industry development on the field collaboration platform, driving the overall ecosystem combining AI innovation with field application.

▲Self-driving vehicle developed by Massive Digital Engineering

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」