【2020 Application Example】 AI data analysis platform for enterprise patent monitoring, complete patent analysis and development trends with one click!

How to efficiently analyze the massive growth of patent information and tap potential value?

Patents are a valuable source of technology, market and competitive information. However, the total number of published patent documents has reached 120 million, with 6.3 million new ones added last year alone. How can we make these massive patent documents available for our own use?

Patent analysis provides an indispensable and practical way to fully tap the value of patent information. Through patent analysis, you can understand the strengths, weaknesses, and opportunities of your own and your competitors' respective patent portfolios, as well as global patent application trends, technology panorama, and possible blank areas.

However, patent analysis requires a thorough understanding of the underlying data, including: the usage and purpose of the data, as well as the problems that can be solved, etc. How to effectively use and analyze massive information is the most troublesome problem...

Unstructured data types can only be read and organized manually, which is very annoying!

"Patent specification" is a legally binding document that combines legal and scientific terms. It is unstructured data. In the past, various search and analysis methods were manually read and organized, which was time-consuming and time-consuming. It often happens that we are unable to keep up with the litigation schedule. When assisting enterprises in patent layout, they often face the difficulty of quantifying the degree of litigation risks faced by competitors and customers, as well as the quality and value of patents. This results in the inability of a domestic enterprise intellectual property management company to further expand its business scope and to promote the outside world. Knowledge of patented value-added applications.

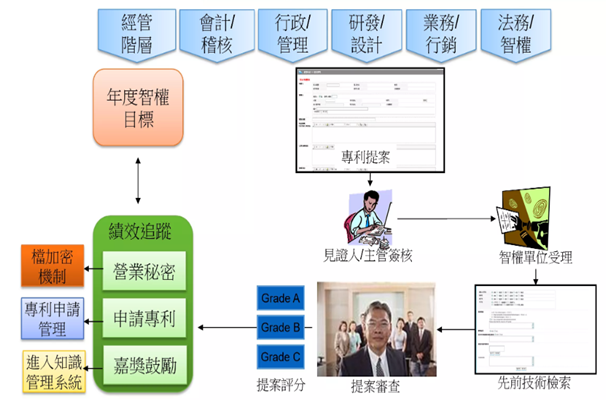

In recent years, enterprise intellectual property management companies have also begun to assist R&D personnel in enterprises to master important technologies and patent competition intelligence that will affect the future development of the industry in advance, allowing relevant personnel to more calmly carry out patent layout and improve patent quality. and value. However, most of the business scope is in the agency of patent software, such as: Intellectual Property Operation Management Information System (IPServ), which mainly assists companies or individuals in managing intellectual property rights, but currently does not provide "patent monitoring" data analysis for companies or individuals. services.

▲Intellectual Property Operation Management Information System (IPServ)

These patent software include patent retrieval, management and maintenance, etc. Whether patent big data can successfully assist companies in understanding market conditions, patent value, litigation threats and monitoring competitors' illegal infringements all depends on the acquisition of patent data. . However, cleaning patent data is very time-consuming, so it has always been a headache. It was not until Taiwan Data Science Co., Ltd. developed the "AI Data Analysis Platform for Enterprise Patent Monitoring" that the light finally appeared...

Traditional patent analysis is time-consuming and time-consuming. Instead, use the "AI Data Analysis Platform for Enterprise Patent Monitoring" to get it done with one click!

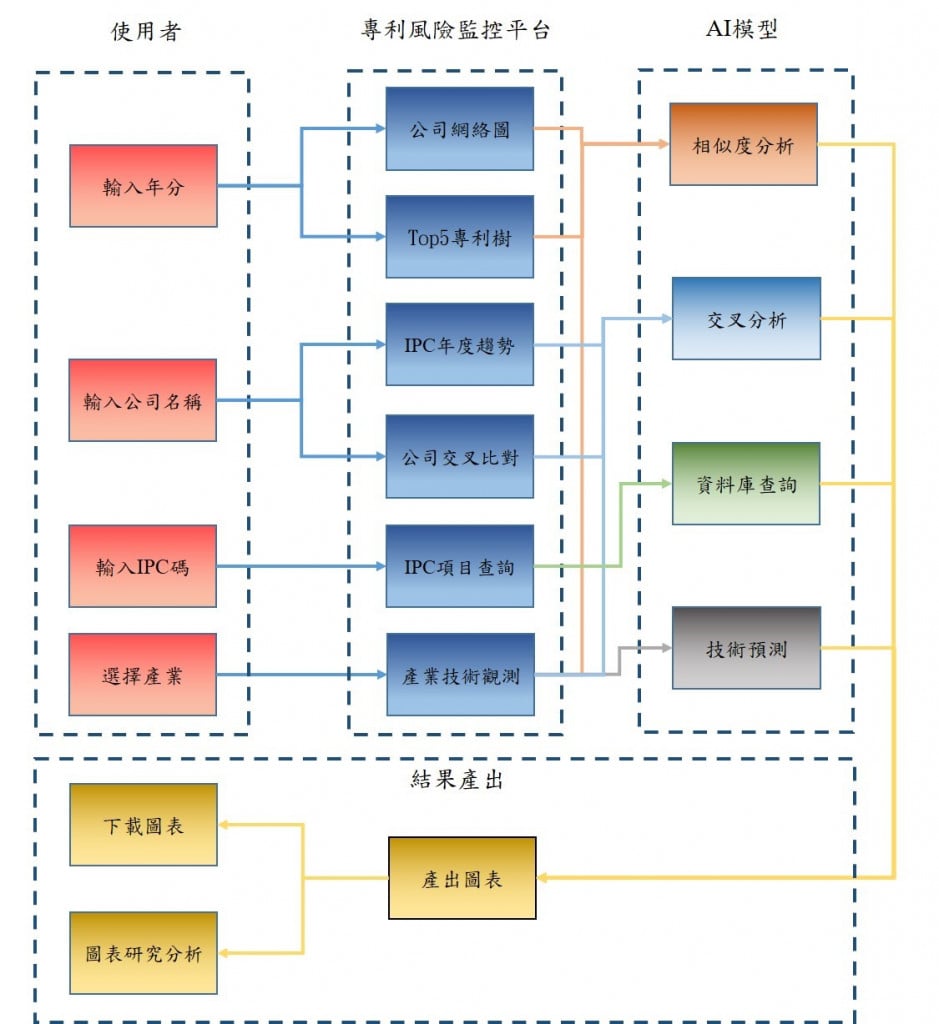

The idea of "AI Data Analysis Platform for Enterprise Patent Monitoring" is to use discriminating influencing factors such as "patent code" and "company industry type" in patent application cases, through big data analysis, and Add relevant news information, and then use machine learning to assist experts through AI to analyze the current market situation, avoid the threat of lawsuits, and monitor competitors' illegal infringements.

These finally extracted factors will also affect the performance of individual stocks. For this, according to different corporate attributes and development directions, "customized big data analysis" can be used to enhance the strategic position of the company. It is hoped that the search through the platform can quickly allow companies to understand the patent layout of competitors when adding new product lines to avoid infringement; or when manufacturers are looking for partners, they can also filter from companies with advanced R&D and This platform serves as a great tool for co-opetition relationships.

▲System operation flow chart

Traditionally, patent analysis is time-consuming and requires manual searching of patents and reading patent information to produce a patent analysis report. Now, through the "Enterprise Patent Monitoring Data Analysis Platform", users can enter After systematic analysis of the company names of your own company and that of your competitors in a certain year, you can quickly know the technical layout, change trend monitoring and other results of that year and among companies, saving work time and manpower.

For example, if you want to know the current development status of related technologies in physics, chemistry, and electricity on the market, you can analyze the IPC patent numbers and check which companies have clusters of patents, so as to determine whether the clustered patents are relevant. Technology or interdependent technology, understand the similarities in patent layout and industry trends between companies, shorten decision-making time, preemptively lay out or make patent avoidance designs.

Using artificial intelligence to improve traditional manual patent search operations to improve work efficiency, the "Patent Monitoring Platform" helps patent analysts more easily understand the current status of patent development in specific technical fields to predict future technology research and development directions. "Patent layout" is when an enterprise builds a strict protection network for its patent portfolio by integrating market, industry, legal and other factors to form a favorable research and development direction and reduce the risk of infringement.

A rigorous patent layout can help companies avoid landmines in strategic planning and avoid unnecessary litigation; or they can expand the scope of protection of their own technology by applying for patents and purchasing patents first. To achieve this goal, The key is to identify trends ahead of peers by analyzing a large amount of patent information. Taking the product line people flow information flow antenna developed by our company as an example, the patent monitoring platform can achieve the above goals based on the patent portfolio of the product.

▲People flow information flow antenna product picture

In the future, text mining (Text Mining) will be conducted on the titles and abstracts of patent document contents. Manual assistance was provided in the early stage, and machine learning was adopted in the later stage to establish a "patent thesaurus automatic word segmentation system". Use this word segmentation system to segment titles and abstracts, and calculate word frequency (TF) and inverted document frequency (IDF). Through statistical methods (such as correlation numbers), the characteristics of patent documents are extracted to find related words with strong correlation between patents. Improve the similarity of exploration patents and better understand the risks of patent litigation.

Collaborate with patent industry players to create a more convenient "Enterprise Patent Monitoring AI Data Analysis Platform"!

By querying the "Platform Network Diagram" of the "Enterprise Patent Monitoring AI Data Analysis Platform", a company or firm can quickly see which patents its related industry companies are laying out. As for "patents", each company can consider whether to apply for all its own research and development, or directly purchase a separate patent license from an industry leader. For "company products", when it comes to commercialization, different strategies can be adopted in response to the changes of the times. They may have been enemies in the past few years, but with the differences in product development, they are allies today.

▲The patent monitoring platform displays the network diagram of Largan Optoelectronics and its related industries in 2009

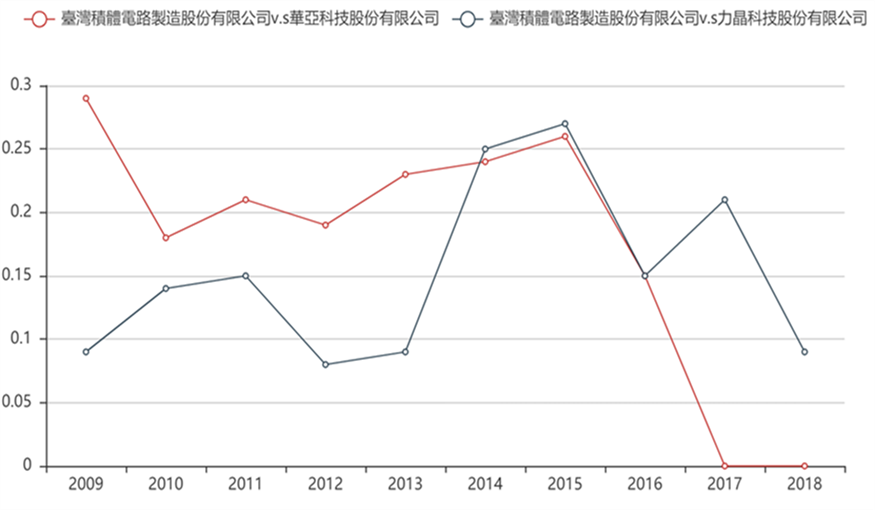

In the "Company Cross Comparison" function query, you can select multiple years at a time. For comparison companies that are highly similar to major companies, you can learn from the annual changes whether the two parties have developed too similar patents, which will make the two companies Being in the middle of a storm of high-risk infringement. When there is more data in the database, the "patent risk rate" can be further calculated, allowing users who are accustomed to reading numbers or charts to quickly understand each other and themselves from another perspective. Even if more parameters are added in the future, the "amount of infringement" can be estimated. However, to obtain the parameter content, it is necessary to cooperate with the patent industry to create a more convenient patent risk monitoring platform.

▲Trends of similarity indicators between TSMC, Huaya Technology and Powerchip Technology

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」