【2020 Application Example】 "Intelligent Agriculture and Big Data Application Platform" effectively reduces fertilizer use by 50%!

Life is tough for lettuce village farmers who are at the mercy of the elements

Global market trends are volatile. In terms of agriculture, it must compete with cities for land and water, and also face other crises, such as: mitigating climate change and protecting natural habitats. In particular, climate change makes it more difficult for farmers to plan cultivation in traditional ways. For organic lettuce exporters, they have to overcome problems such as climate and pests to ensure that the lettuce can meet the standards of overseas customers. This is an issue that the industry is facing...

Difficulties and needs of Taiwan Lettuce Village

Although Taiwan Lettuce Village currently uses an internationally certified standard process (G.GAP) for cultivation, and also uses the "Intelligent Agriculture Management System" developed by Info-Link Services for cultivation management, it still faces the dilemma of not being able to control crop yields and quality due to climate abnormalities.

Efforts to solve pests and production problems in recent years not only consumes labor, but also doubled the use of pesticides. However, using cultivation and production models of the past will cause the industry to stagnate or even face elimination.

Therefore, it hopes to add value through AI, and make the lettuce village can be more information-based, intelligent, analytical, and predictive in cultivation, so as to expand the industry’s exports and diversify the industry's development in the future.

Current Demand of the Lettuce Village

The agriculture industry in Taiwan Lettuce Village currently only implements "information management." Even though it has the concept of data application, there are no implementation methods and direction, and fields are still manually inspected and the dosage of pesticides is determined based on experience. Since crop production varies due to environmental factors each season, the accumulated temperature conditions required for lettuce growth can be estimated by comparing crop yield and harvest date based on historical meteorological data, thereby establishing an accumulated temperature calculation module to estimate the cultivation schedule, allows the system to automatically analyze and make prediction based on the current temperature and humidity of the overall environment. During the crop harvesting period, it assists field personnel in optimizing their work, reducing the need for daily inspections to determine when to schedule the next task.

Agricultural information system + AI allows lettuce to grow smoothly

"The stability of the cultivation environment" plays an important role in the growth process of crops. Understanding the growing conditions of crops can greatly increase production and maintain a certain level of quality. Combined with "smart equipment in the field" and "linebot," field management can be carried out and warnings can be received at any time, allowing managers to respond quickly to reduce potential losses, and assist in disease prevention, growth period, and harvest prediction. It can be further integrated with data from the Central Weather Administration to establish a "cultivation database," and conduct agricultural analysis through data collection, such as: fertilizer dosage planning, analysis of lettuce growth days in different months, analysis of the quality and weight of lettuce output based on temperature, and even disease prevention predictions.

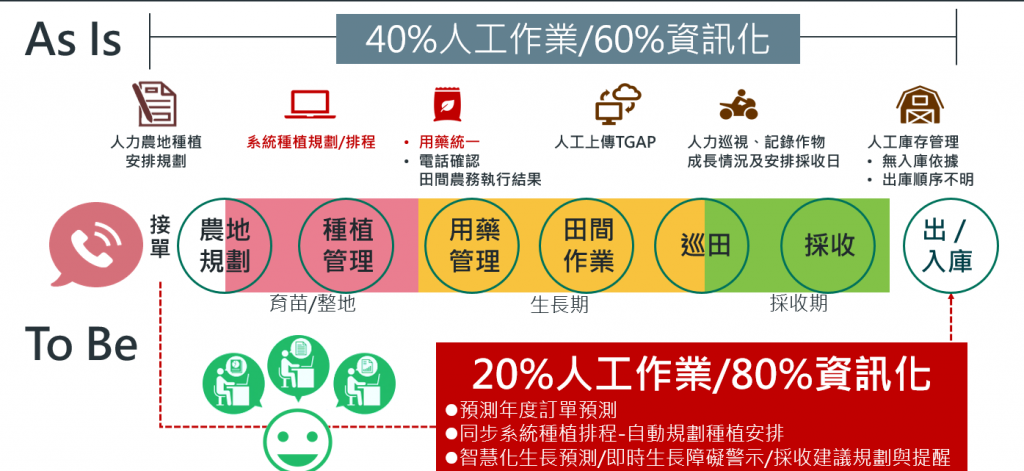

▲ Comparison of differences before and after digitization

Compiled the cultivation data collected by the Lettuce Village from field equipment and external data , such as: temperature, humidity, sunlight, and farmland fertility, and applied the data in four aspects, including:

1. establishing crop progress and growth obstacle information, analyzing the temperature ranges that are suitable for growth and hinder growth, importing open data (real-time and future weather forecast data) to establish forecast standards, and using weather sensing equipment for field monitoring, in order to achieve real-time warning notifications and preventive effects.

2. Utilize cultivation data for growth predictions, in order to achieve the goal of estimating harvest date.

3. Using mobile phones for weather monitoring achieves the goal of real-time control and adjustment of field operations, allowing Lettuce Village to effectively manage manpower, material costs, and crop quality.

4. Compiled farmland fertility data to provide the fertilizer ratios for suitable for farmland and reduce the frequency of fertilization, improving farmland fertility while improving the overall environment.

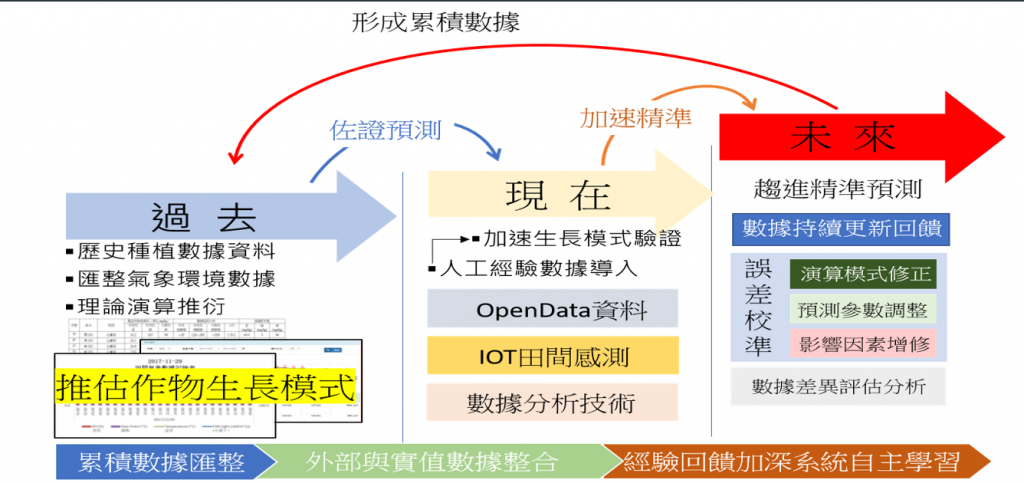

▲ Description of Data Applications

The system will continue to be optimized and promoted it to more units

The "Intelligent Agriculture Big Data Application Platform" allows farmers in Lettuce Village to no longer be limited to the traditional agricultural business model, achieve systematic cultivation and production management, and standardize specifications to improve quality, stabilize output, and reduce labor consumption and material costs.

Improved pest and disease detection accuracy from 80% to 100%

In the future, we hope to increase the accuracy of pest and disease detection, so that farmers can monitor the status of crops in real time, making the system more complete. We also hope to apply this system model to more crops, and allow more farmers to consistently grow high-quality crops at low cost through government promotion.