【2020 Application Example】 E-commerce Direct Purchase Order Parsing Automation Robot Solves Inventory Issue

Guo Fang Enterprise, the largest professional Velcro factory in Taiwan, produces Velcro, commonly known as hook-and-loop fasteners. World-leading medical equipment suppliers like DJO and the zipper-originated company YKK are among its clients. Guo Fang has gained the trust of major manufacturers like YKK mainly by implementing intelligent manufacturing, allowing effective inventory management with the introduction of an e-commerce direct purchase order parsing automation robot, thus solving all inventory problems.

Guo Fang Enterprise, a leading Velcro (hook-and-loop fasteners) manufacturer, was established in 1984. Initially, it had 30 employees, and now it employs over 330 people across Taiwan and Vietnam.

Guo Fang Enterprise offers a complete service from raw textile mills, weaving mills, dyeing and finishing mills, to setting mills. Through tensile and color testing, professional computer analysis is used to select pigment combinations and ratios, providing stable product quality, effectively differentiating in the market, and establishing a leading position in the high-quality Velcro market, selling to over 60 countries across five continents. Top global medical equipment suppliers like DJO and international giants like YKK are among Guo Fang's clients.

Currently, up to 15 e-commerce platforms rely heavily on manual labor for order sorting, inventory management, and shipping tracking, rendering human resources ineffective in product and market development. Although additional temporary workers are employed, updating a single e-commerce platform's information requires working until the following February, making it difficult to respond quickly to market demands. Limited by human resources, product information details are insufficient, causing difficulties in improving product ratings on platforms like Amazon.

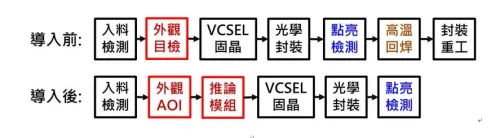

Introducing AI Robots to Fully Control Product Inventory Information

The team at the Information Management Agency, addressing the aforementioned issues, provided an e-commerce direct purchase order parsing automation robot for trial. Based on the new product information provided by Guo Fang, it automatically lists products on e-commerce platforms and periodically checks orders.

Guo Fang's ability to gain trust from major manufacturers like YKK is primarily due to the introduction of intelligent manufacturing. The manufacturing process variables such as temperature, humidity, and speed are quantified into data, which not only allows for efficiency improvement and reduced wastage after accumulating a large amount of production data but also enables small-scale diversified production. Even orders for less popular items can be accepted.

Due to the characteristics of small-batch diversity, Guo Fang Enterprise has to process over 4,000 orders annually into shipping documents. Usually, it takes about 15-30 days to issue documents and deduct inventory, resulting in always inaccurate inventory records. Therefore, the team at the Information Management Agency has utilized an AI software robot solution to develop a POS inventory management automation robot application. Upon order placement, no manual dispatch is needed for issuing; it automatically connects to the POS to deduct inventory, instantly synchronizing inventory amounts in the POS system across all platforms, ensuring the reliability of product inventory information.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」