【2021 Application Example】 Savior of Wastewater Treatment: Combining Big Data and AI Technology Opens Another Horizon in the Environmental Industry

As water resources deplete and environmental protection needs increase, wastewater treatment plants have increasingly adopted AI technology to assist in monitoring and warning systems. Zhongxin行's integration of big data and AI technology has opened up new possibilities in the environmental industry. In the future, besides boosting the technological momentum of the wastewater treatment industry, it can also be promoted to other industries to foster technological and economic development.

Founded in year 1980 as Zhongxin Engineering (later renamed to Zhongxin行 Company Limited), it is one of the largest and most technically equipped environmental companies in the domestic operation and maintenance field. Zhongxin行's achievements in the operation and maintenance of sewer systems span across Taiwan, including science parks, industrial zones, international airports, schools, collective housing, national parks, and factories.

Introduction of AI systems in wastewater plants Precisely reduces medication addition times and lowers the risk of penalties for water quality violations

At the wastewater treatment plant in Hsinchu Science Park, Zhongxin行 introduced the 'AOMBR Carbon Source and Aeration Intelligent Enhancement Control System Development,' which accurately predicts air volume control and reduces medication times, thus lowering the risk of hefty fines. Zhongxin行 points out that with the vigorous development of advanced industries and increasingly strict effluent standards, a slight misalignment in equipment control can lead to major discrepancies in water quality.

In recent years, many wastewater treatment facilities have incorporated automatic control functions, yet onsite conditions often deviate slightly from theoretical expectations, causing situations where good treatment technologies must continuously adapt and adjust to achieve effective effluent water quality control. 'The better the quality of the effluent, the greater the pressure on the operators. This is the biggest pain point for Zhongxin行,' said a senior manager candidly.

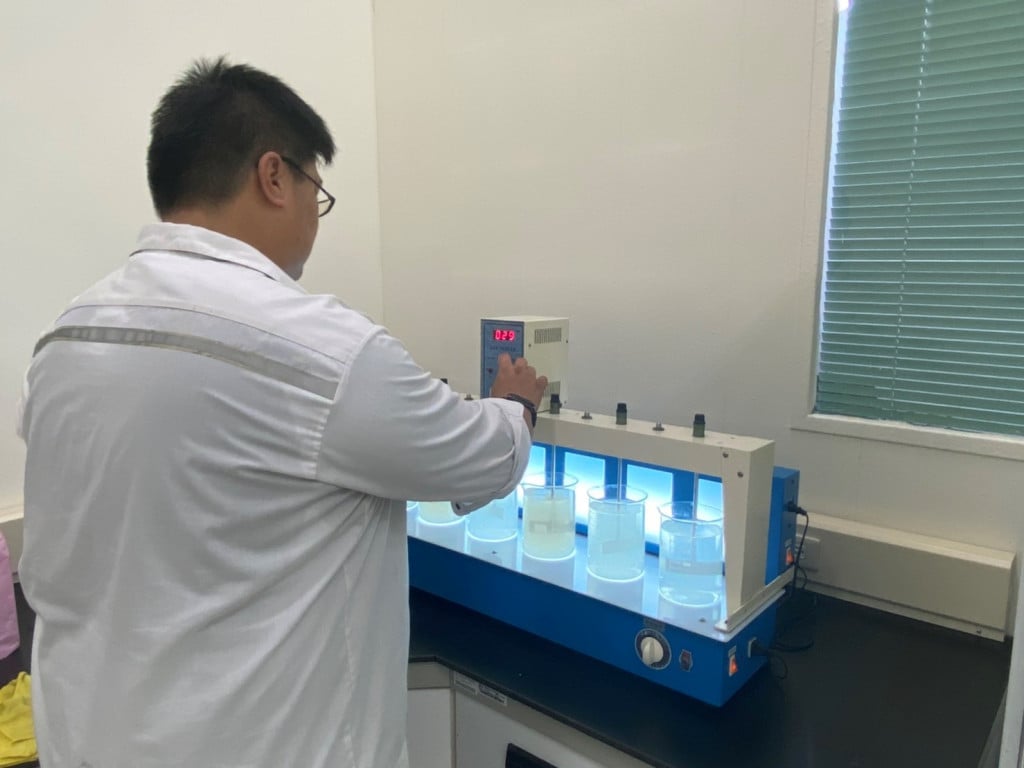

▲ Regular water quality testing and equipment maintenance ensure that effluent water stays below legal standards.

This means that operators need to be on top of equipment and water quality conditions daily. If there are sudden anomalies in influent water quality or equipment malfunctions, linked issues can lead to pollution. Therefore, besides performing regular maintenance and testing, it is critical to constantly monitor the dashboard to ensure system stability, consuming both manpower and mental energy.

Zhongxin行's on-site operators work 24-hour shifts, constantly monitoring effluent water quality. Combined with laboratory water testing and analysis, if the wastewater treatment values do not meet requirements, they face both administrative and contractual fines from environmental agencies and granting authorities, which also create significant psychological pressure on the employees.

Over the years, Zhongxin行 has built up a vast database of water quality information and invaluable experience passed down among employees, allowing a comprehensive understanding of the entire system's operational characteristics. Moreover, by analyzing equipment or water quality data for key signals, problems in the treatment units can be pinpointed. If AI technology could be adopted to replace manual inspections of wastewater sources and generate pre-warning signals for systematic assessment, it would significantly alleviate the pressure on staff.

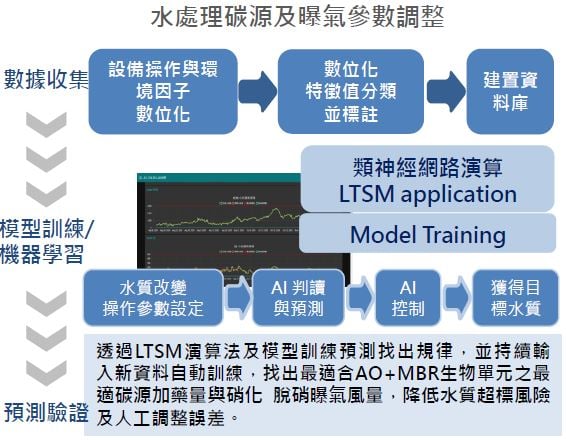

Response time reduced from 8 hours to 4 hours, saving half the time

By implementing 'AOMBR Carbon Source and Aeration Intelligent Enhancement Control System Development,' Zhongxin行 utilizes accumulated wastewater data along with verbal recounts of operator experiences on-site. With the support of AI technology and environmental engineering principles, key parameters in the biological treatment unit such as carbon source dosages and aeration can be effectively controlled. Through the AI transformation of wastewater treatment, a balance is achieved among pollutant removal, microbial growth, equipment energy conservation, and operation economization, achieving rationalized control parameters.

▲ Carbon source and aeration parameter adjustment steps range from data collection, model training to prediction verification.

In the long run, incorporating historical data calculations, AI can operate within known boundary conditions, not only recording past water quality and equipment operational characteristics far more accurately, but also developing predictive models to find optimal solutions that offer the best results in terms of chemical use, energy saving, reduced greenhouse gas emissions, and pollutant removal.

According to Zhongxin行's estimates, originally due to human parameter adjustments leading to errors, controlling response time would take about 8 hours. With the introduction of AI technology, not only can measurement errors be reduced, but also the control response time can be shortened to 4 hours, saving around half the time. This enhancement increases the turnover rate of personnel and effectively reduces the risks of penalties due to operator errors and thus markedly reducing the pressure on employees.

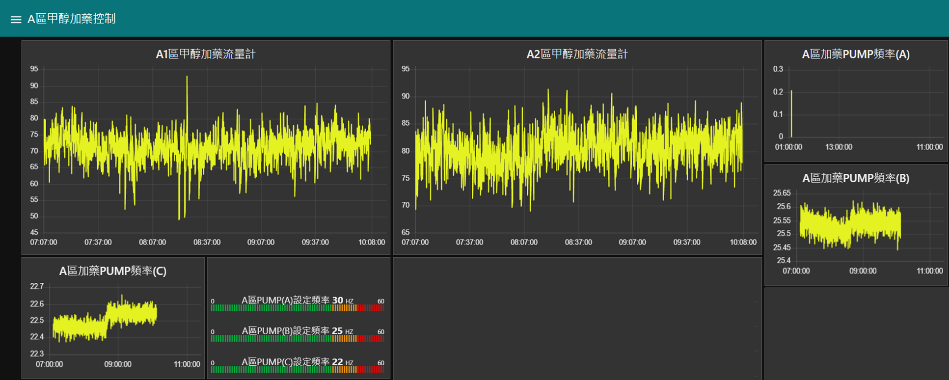

▲Dashboard digital display panel illustration

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」