【2021 Application Example】 Life-saving is as urgent as a spark AI critical illness system monitors and grasps the golden rescue period

60-year-old Mr. Huang was admitted to the hospital due to a stroke. After lying in the intensive care unit for two weeks, his condition suddenly took a turn for the worse. After rescue, he was lucky enough to survive. In fact, with the assistance of AI critical illness early warning technology, hospitals can detect signs and take timely and accurate medical measures 6-8 hours before a patient's heart stops, which can greatly reduce the chance of death in the hospital.

The deterioration of the condition is a process that evolves over time, and its subtle changes are by no means without context. Previous research reports show that about 60 to 70% of inpatients who experience unexpected in-hospital cardiac arrest had symptoms 6 to 8 hours before their cardiac arrest, but only a quarter of them were recognized by clinical staff. Detection and discovery, therefore, there is a need for a risk warning tool or system that can be used earlier and continuously to monitor the condition, alert medical staff to pay attention to subtle changes in the patient's condition at any time, and take timely and accurate intervention measures before the condition progresses to effectively reduce adverse events. or the risk of serious adverse events.

Unexpected deterioration cannot be detected early

Acute and severe patients often undergo unpredictable changes, and timely detection or prediction of potential acute and severe patients is an important issue. The currently commonly used clinical assessment method is Modified Early Warning Score (MEWS), which uses simple physiological parameter assessment (including heartbeat, respiratory rate, systolic blood pressure, body temperature, urine output and state of consciousness) to screen out high-risk patients, and has been proven to be predictive. Patient clinical prognosis.

MEWS is a scoring mechanism with a single time point and a standardized formula. However, the AI crisis warning system developed by Boxin Medical Electronics - Hospital Emergency and Critical Care Early Warning Index System (EWS) is designed to predict patient status with immediate response. , collect the physiological data of patients over time for deep learning, find the best prediction model, and improve the overall accuracy.

Boxin Medical Electronics uses a big data analysis model to build an early warning system (EWS), IoT Internet of Things and 5G communication technology, allowing medical staff to remotely monitor the physiological status of patients through communication equipment, and monitor emergency and severe cases quickly The patient's condition changes and the golden rescue period of 6-8 hours before cardiac arrest can be grasped.

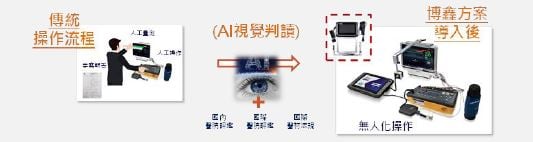

▲After Boxin Medical Electronics introduces AI visual interpretation, unmanned operation can greatly reduce medical manpower

The AI technology developed by Boxin Medical Electronics is the Gradient Boosting Ensemble Learning System (GBELS) to build an early warning system. It is a learning-based EWS prediction algorithm developed by the company, which is an integrated learning ( Ensemble Learning) and is classified as supervised learning, providing the following three functions:

1. Early warning risk notification is used to analyze representative data using GBELS to provide an early risk score so that medical staff can conduct immediate clinical assessment and provide appropriate medical treatment.

2. Reduce medical manpower: Collect continuous physiological monitoring data, such as heartbeat, respiration, blood pressure and blood oxygen concentration, etc., to reduce the time for medical staff to write cases.

3. Combine IOT logistics network and 5G communication technology to quickly transmit medical data such as monitoring parameters and imaging data, and assist medical staff to monitor changes in patients' condition remotely through communication equipment.

AI critical illness system monitoring to master the golden treatment period

Boxin Medical Electronics stated that assessing the severity of the disease in acute and severe patients is a complex task, and patients often experience unpredictable changes. Clinical medical staff often judge the condition based on their own clinical experience or intuition, which lacks science and objectivity, resulting in the inability to correctly identify and timely detect potentially acute and severe patients, resulting in or misdiagnosis leading to increased in-hospital mortality of patients. The introduction of an AI early critical illness warning system can assist emergency and critical care medical staff to correctly predict the patient's condition and allow patients to receive the care they need immediately. This can reduce the manpower arrangement of the emergency and critical care ward at the same time and reduce labor costs.

In addition, the easy-to-carry design will help the system be introduced into ambulances, home care and other places in the future, so that emergency patients can receive appropriate care earlier. Other departments within the hospital can also develop new applications around this system, which can effectively accelerate the development and promotion of smart medical technology. With the COVID-19 epidemic still raging in many countries around the world, this system can also help hospitals in various places to operate more effectively. Caring for and monitoring the condition of critically ill patients.

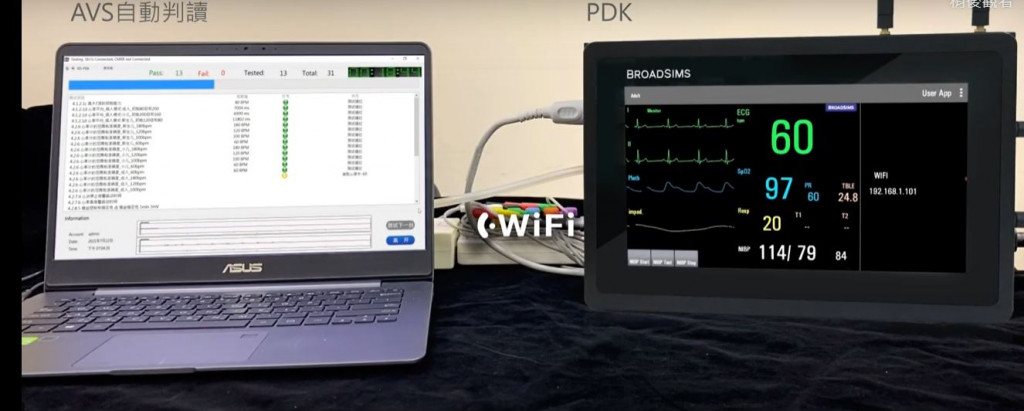

In addition to AI critical illness warning, Boxin Medical Electronics has also developed AI image interpretation - Medical Physiological Monitor Life Cycle Compliance Testing (AVS), which uses AI image interpretation technology to develop automated quality inspection of life support medical equipment. The instrument solves the time-consuming problem of medical instrument testing. It can reduce testing time by 70%, increase the number of tests by 3 times, and effectively reduce labor costs by 50%. At the same time, it is 100% compliant with regulatory requirements, and gradually solves the shortage of manpower and medical resources in the medical field. , medical work overload and other issues. It has now taken root in mainland China and is actively preparing for its launch in Europe. It will develop towards the Japanese and American markets in the future.

▲Boxin Medical Electronics develops AI image interpretation-medical physiological monitor life cycle compliance testing (AVS) to solve the time-consuming problem of medical instrument testing and can reduce testing by 70% time.

At this stage, Boxin Medical's smart medical technology has been introduced into medical hospitals including Hsinchu MacKay, Changkei, Dongyuan General Hospital, Kaohsiung University of Technology Affiliated Hospital, Zhenxin Hospital, Hsintai Hospital, Taipei Medical University Affiliated Hospital, etc. GE Healthcare.Inc, an internationally renowned medical materials manufacturer, and Mindray Medical, China's largest medical materials manufacturer, are both representative customers of Boxin Medical Electronics.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」