【2021 Solutions】 Wisdom Stabil Tech's Domain AI SaaS Enables Industry-Ready AI Application

From AI projects to AI products, Wisdom Stabil Tech has spent five years on this journey!

With experience in implementing AI across more than 10 fields and 30 enterprises, Wisdom Stabil Tech has developed the Domain AI SaaS platform to help companies rapidly integrate AI technology, saving an estimated 50% or more in time.

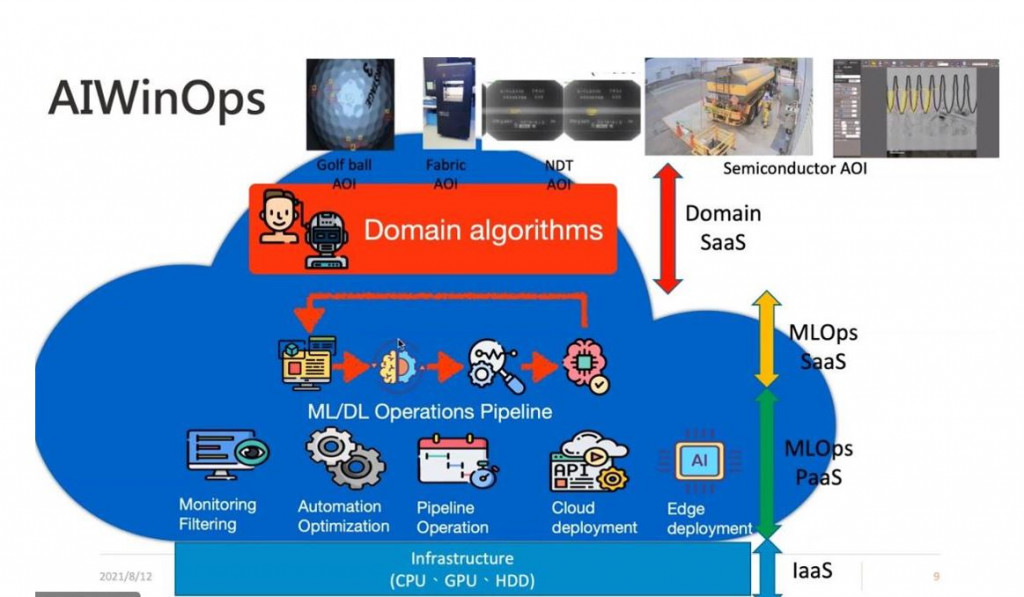

Founded in 2016, Wisdom Stabil Tech provides AI image recognition solutions for smart factories. Their Domain AI SaaS platform assists clients in data cleansing, tagging, AI training, modeling, and the integration of hardware and software, leveraging the latest AI algorithms for practical implementation.

Five years of refining project experience has honed Wisdom Stabil Tech's AI products

The general manager of Wisdom Stabil Tech, Lin Gengcheng, said that the company has extensive on-the-ground AI experience in fields as diverse as golf, textiles, petrochemicals, semiconductors, and water resources, with numerous application cases accumulated.

▲慧穩科技累積豐富AI專案經驗,推出Domain AI SaaS平台。圖為平台系統架構圖。

He analyzed that there are three major pain points to successful AI implementation in the industry:

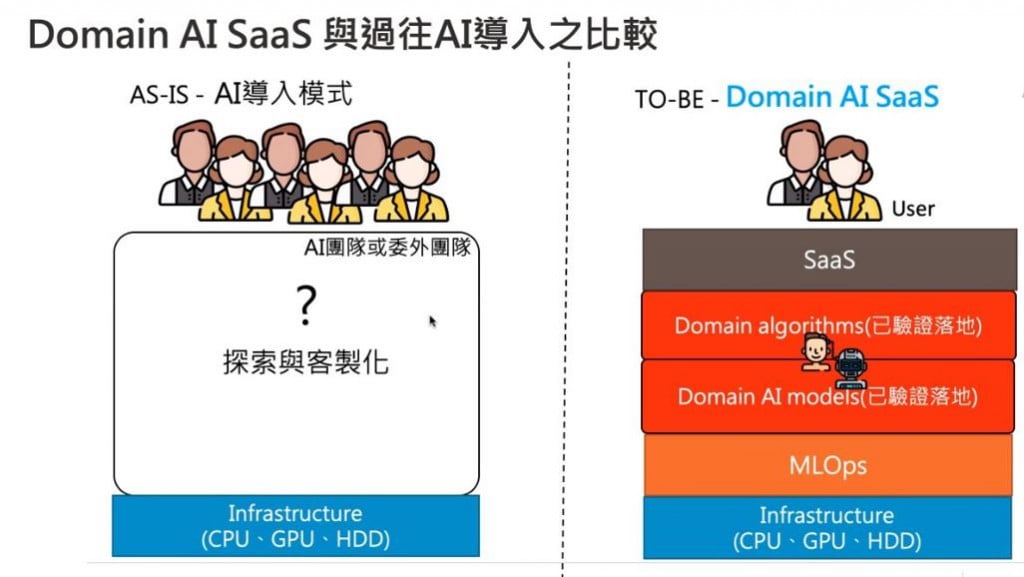

Pain point one, talent shortage: From traditional industries to high-tech semiconductor businesses, it's extremely challenging to find dedicated AI technicians with domain expertise, especially in traditional industries and SMEs. Instead of spending time looking for AI talent, it's more effective to use existing AI platforms that require no coding. This allows domain experts to use, operate, and maintain AI, addressing the current shortage of tech talent.

Pain point two, difficulty assessing implementation results: According to reports, the success rate of AI implementation isn't high, with only about 5% of international AI implementations creating significant value. Wisdom Stabil Tech also finds that their AI implementation success rate is about 5% to 10%.

Lin Gengcheng analyzed that a major difficulty lies in the process of implementing AI, which requires defining the problem, understanding domain knowledge, applying AI models, and combining systematic integration. Generating business value through these steps requires extensive interdisciplinary integration and is exceedingly challenging, necessitating significant time and human resources.

Pain point three, cost. Whether it's the introduction of talent, time, or the integration of domain knowledge with AI, the processes demand substantial time. This leads to directionless investments and ever-increasing intangible costs. If AI hardware is also factored in, the resulting financial burden makes it difficult to assess cost versus benefit.

To address the pain points of AI adoption in industries, Wisdom Stabil Tech will assist enterprises in utilizing AI to solve process or production line challenges with their proven AI models, creating standardized AI SaaS to tackle common domain issues. For individual or custom needs of enterprises, adjustments will be made based on this standardized base. Currently, Wisdom Stabil Tech offers two primary services: the Optical Inspection AI SaaS platform and the Smart Water Management AI SaaS platform, both of which are easy to monitor and maintain, enabling companies to introduce AI technology in a cost-effective and efficient manner.

▲企業導入Domain AI SaaS產生成本下降、效率提升等具體成效

In the realm of optical inspection, using the Domain AI SaaS platform can lead to a 10x increase in quality and a reduction in labor costs by 50%. In the smart water management sector, it can achieve a 20% improvement in energy optimization.

For instance, in the textile industry, where manual inspections traditionally detect defects at a rate of 80-90%, the introduction of AI optical inspection technology can increase this rate to over 95%. This not only significantly enhances the defect detection rate by 10% but also halves labor costs.

舉例而言,紡織業瑕疵檢測過往採用人工全檢的過程中,通常檢出率在80%-90%之間,導入AI光學檢測技術之後,檢出率可以提升到95%以上。之後再透過人工進行複檢或抽檢,不僅可大幅提升10%的瑕疵檢出率,還可節省將近一半的人力,效益十分可觀。

Furthermore, in wastewater treatment plants that traditionally observe water quality samples managed by experienced technicians manually adjusting equipment, AI can optimize motor and equipment output based on monitoring data, maintaining water quality within specified standards and potentially saving over 20% in energy costs. This is essential for municipal wastewater plants and water utilities needing smart water management platforms to monitor treatment processes.

Lin Gengcheng honestly mentioned that AI is not a cure-all and can act as a 'revealing mirror,' exposing issues previously overlooked by manual processes. Thus, defining the problems with clients and adjusting how results are verified is critical.

With ambitions on the Southeast Asian market, Wisdom Stabil Tech estimates achieving an IPO in 5 years

Lin Gengcheng also stated that AI technology needs continuous refinement. At present, the goal is to not overly rely on massive data for effective AI learning. Combining traditional algorithms with current AI technology offers the best solution before comprehensive AI advancements emerge.

Besides promoting domestic industry applications, Wisdom Stabil Tech plans to expand the Domain AI SaaS platform to Southeast Asia in 2022. They are currently active in Series A funding, aiming to further enhance the depth and breadth of the Domain AI SaaS. They plan to conduct Series A+ or B rounds of funding with the goal of going public in about five years.

▲慧穩科技團隊

▲慧穩科技創辦人兼總經理林耿呈

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」