【2022 Solutions】 Insight into consumer behavior and intelligent interpretation using AI to assist the catering industry with smooth transformation

In May 2021, due to the local COVID-19 outbreak, a ban on internal use was adopted, making the catering industry feel like it has entered a cold winter, with business bleak and operations facing difficulties. However, there are also catering companies that have turned the crisis into an opportunity and actively carried out digital transformation, introducing online ordering and delivery platform systems, establishing customer membership systems, etc., to effectively reduce inventory and increase sales. Intelligent Interpretation, a new start-up company established just one year ago, acts as a transformation consultant for the catering and retail industry, collecting, connecting and analyzing consumer behavior data to provide the best solutions for the catering/retail industry.

Li Qihan, the founder of Intelligent Interpretation, is good at online marketing and website construction. As AI technology continues to evolve, he graduated from the Northern Phase II Manager Class of Taiwan Artificial Intelligence School (AIA) and was impressed by the large number of website sales. Data and marketing analysis data can help companies improve their competitiveness and reduce operating costs. Therefore, we established an intelligent interpretation company with Taiwan Artificial Intelligence School alumni, hoping to use member information to start collecting more first-party data to help customers build customer vision. Analyze the data and identify relevant sales opportunities.

Targeting the catering and retail industries, intelligent interpretation helps stores use AI to transform

"There are many small and medium-sized restaurants in Taiwan. We hope to help these small and medium-sized restaurants use simple cloud services and social tools, such as Line, to start collecting and establishing member information systems and collect relevant information. Consumption data is used to establish behavioral models of different consumers." Li Qihan went on to say that the catering and retail industries will be targeted at the initial stage, and different consumption behavior analyzes will be used to help stores further increase the frequency of customers visiting the store and the frequency of dining or purchasing, and reduce the use of ingredients. Preparation costs.

▲The main features of the AI service of intelligent interpretation

Affected by the ongoing epidemic, which has severely impacted the performance of physical stores, intelligent interpretation also assists physical stores in establishing e-commerce websites or shopping malls, combining physical and virtual consumption data to provide 360-degree OMO consumers Analysis, and can send marketing messages to different consumers, reducing the large-scale and indiscriminate casting of traditional marketing methods that cause customers to blacklist merchants or block lines, and also increase consumers' willingness to click and purchase Will. Li Qihan pointed out that the AI service of intelligent interpretation has the following characteristics:

1. Use LINE@ combined with membership system

2. Use QR Code to replace membership card

3. Provide LINE online ordering/reservation

4. Use AI to analyze consumers’ personal preferences

5. Send coupons based on consumer behavior and preferences.

Using Line ordering information, you can understand consumer behavior such as consumer type, taste, time period, ordering frequency, etc., find consumers of the same group, and conduct summary analysis, which is important for one-to-one customized marketing. Reference. Li Qihan emphasized that the cost of digital marketing at this stage is very high. If there is no classification and grouping after acquiring customers, preferential information will be distributed randomly and easily blocked by consumers. The conversion rate will become lower and lower, and the marketing budget invested previously will be in vain.

AI combines the advantages of MarTech to provide exclusive customized services

Although Intelligent Interpretation is a new startup that has been established for nearly a year, in terms of the company's future development strategy, Li Qihan hopes to use MarTech combined with the advantages of AI to first assist the catering and retail industries that are currently most in need of digital transformation. Quickly enter the first stage of digital transformation, establish member information and collect consumer data, and then assist these companies to enter the second stage of digital transformation, analyze and use these consumer data, and provide exclusive customized services.

Li Qihan said that Taiwan’s MarTech market still has considerable room for development. Most companies think that advertising on the Internet is the so-called MarTech, or that combining website data with advertising conversion rates and looking at the GA report (Google Analytics) every day is the so-called MarTech. However, he believes that the above situation is only It stops at the collection and analysis of marketing data and is not integrated into the corporate sales and management levels. In fact, after the data is collected, it still needs to be integrated, analyzed, and applied according to individual business scenarios. This is the real MarTech application method.

▲Li Qihan, founder of Intelligent Interpretation, shared his smart retail experience at the AIGO forum

As for most companies that believe that as long as they have data, AI algorithm analysis can solve all problems, Li Qihan suggested that companies should have a correct concept of data. First, it does not have to be big data. AI algorithms can also work with small data. Great effect; 2. Data is accumulated year by year. To collect information, you need to understand the purpose and needs. After collecting data, you need to find out its correlation. That is to say, first define the use situation and the problem you want to solve, collect data, Only by analyzing data and using machine learning to identify undiscovered sales opportunities can we start to provide marketing application suggestions.

"The key to the success of using technology for digital transformation lies not in technical issues, but in concepts. AI is not a magic pill that will take effect after taking it. AI is more like a health food and must be taken continuously to help adjust the corporate body." This is Li Qihan realization. He also mentioned that there is an 80/20 rule in customer management. How to define the 20% customer group? What is the definition of VIP customer? What issues does the company want to analyze? What data should be disassembled? It is necessary to peel off the cocoons layer by layer and clarify the above issues one by one. This is the "basic project of the sewer." If the foundation is stable, there will be no problem in building a few more floors on top.

The Industrial Bureau of the Ministry of Economic Affairs’ AI problem-solving competition creates a win-win situation for enterprises and innovations

Intelligent Interpretation has assisted the internationally renowned catering chain Din Tai Fung to participate in the AIGO "Problem Solving" competition of the Industrial Bureau of the Ministry of Economic Affairs. It understands that almost all catering industries have problems with how much to prepare. Many times, when there are too many guests, there is insufficient preparation. There are fewer customers, resulting in a waste of ingredients. Therefore, it is very important for restaurants to predict the number of customers every day. Intelligent interpretation suggestions can be based on weather, store location, and special holidays (such as Valentine's Day, Mother's Day, etc.) through AI. , special time (parents’ birthday, wedding anniversary) and other data correlation analysis, the estimated number of guests is expected to increase the accuracy by more than 80%, effectively using AI to solve the problems of catering operators.

< /figure>

< /figure>

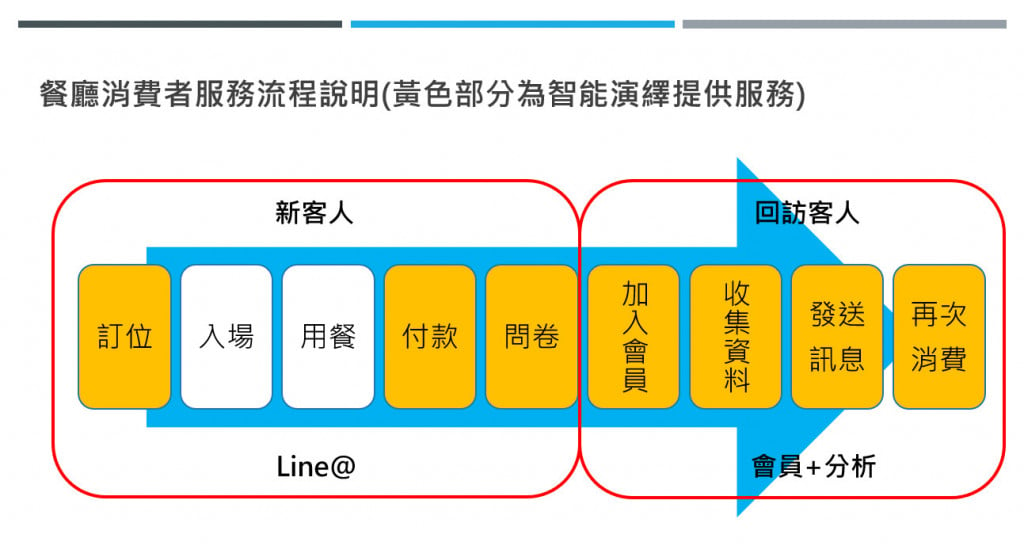

▲Restaurant Consumer Service Flow Chart

Li Qihan pointed out that "industry problem solving, new innovation problem solving" can help enterprises and AI startups find common goals, and also solve the dilemma of new startups not getting usable data, and provide identification through matchmaking on the enterprise side. Based on the data, AI startups can put algorithms into practical application, and enterprises can also get solutions for digital transformation, creating a win-win situation.

After the epidemic, digital transformation is related to the life and death of enterprises. How should the catering/retail industry choose AI companies and introduce them? Li Qihan, who currently serves as an AIGO smart retail coach for the Industrial Bureau of the Ministry of Economic Affairs and a number of AI consultants, said frankly that if data analysis does not have a certain degree of understanding of AI and practical implementation experience, there may be a high chance of failure in project execution. In the retail industry, when it comes to choosing an AI project company, it is best to choose a company that has actually introduced AI projects or has experience in operating e-commerce.

The recommended principles and steps for introducing AI into the catering/retail industry are: If the problem the company asks is too big, it needs to continue to dismantle it. Because different problems naturally require different ways of collecting data, with the help of consultants step by step After dismantling, use the data collected according to the usage situation to analyze, and you will naturally get the answer to the problem you want to solve. After you find a certain accuracy, you can then use transfer learning to solve similar problems one by one. Looking to the future, Intelligent Interpretation hopes to become the number one AI company in Taiwan in the catering and retail industries, using simple and practical methods to help the catering and retail industries implement AI and improve the competitiveness of Taiwan's industry!

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」