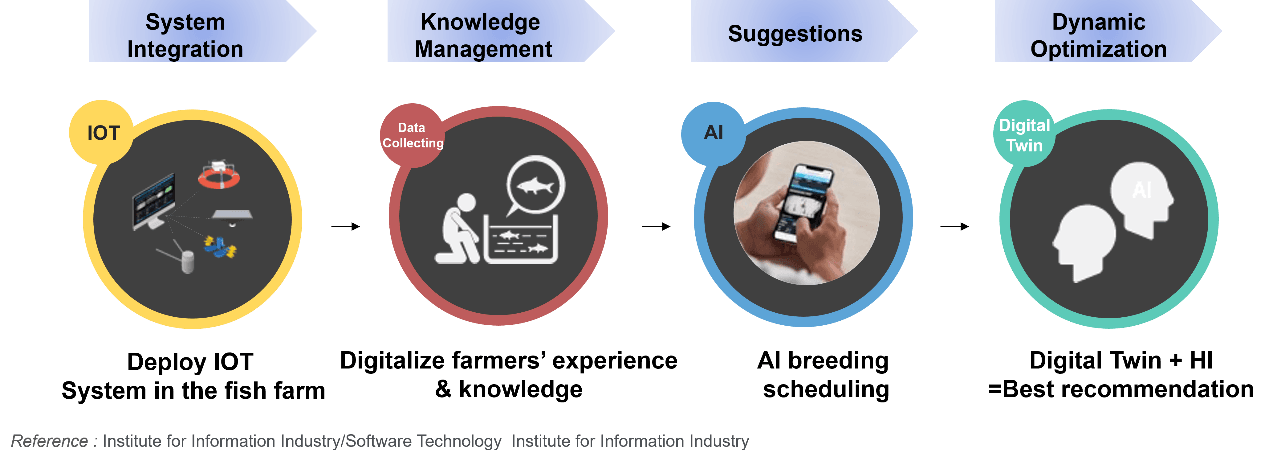

【2019 Application Example】 Smart agriculture and fisheries digital twin: A highly efficient and sustainable agriculture and fisheries upgrade solution. How did the AI technology called "digital twin" triple the output of aquaculture?

Relying on nine types of sensors to detect water quality, while monitoring the growth of the farmed species and fishermen's behavioral decisions, the artificial intelligence (AI) solution "Smart Agriculture and Fisheries Digital Twin" can significantly increase production by 300%. The “Happy Harvest” - style high-tech integrated solution allows novices to get started quickly. It significantly reduces the reliance of agriculture and fisheries on experience, and makes it more appealing for young people to return to their hometowns to work in agriculture and fisheries.

There was a time when Facebook games were just starting to become popular, and everyone could be called a farmer due to the popular game “Happy Harvest.” Office workers took out their mobile phones one by one during their lunch breaks and started living the life of a happy farmer life on their mobile phones. Some people were naughty, secretly went on Facebook during work hours to steal the harvest from their colleagues. The game was so therapeutic that some people actually went into the fields to become farmers during the holidays. If I said that "Happy Harvest" really exists, would you believe me? THE "Digital Twin" -"Smart Greenhouse" and "Smart Farm" solutions developed by the Innovative DigiTech-Enabled Applications & Service Institute (IDEAS). Institute for Information Technology (III) are "Happy Harvest" and "Happy Fish: Dream Aquarium" in real life.

Here, nine sensors based on IoT will continuously monitor the "facility factors" of the crop/aquaculture growth environment, such as water quality, and upload them to the cloud through the control box. The AI robot in the cloud will continue to simulate a digital twin in the system, receiving "facility factors" such as water temperature and dissolved oxygen, and continuously collecting "growth factors" for the growth status of crops/farmed species. A simulated "digital twin" of the fisherman is created in the cloud system, and the AI robot will also calculate appropriate "behavioral decisions" based on the successful strategies of past fishermen.

When the oxygen content is low and the water temperature exceeds the standard, AI will suggest you to make behavioral decisions, such as turning on the water wheel, turning on the aerator, or using medication. Fishermen use their own experience or knowledge to decide whether to follow the suggestion. Afterwards, the system will compare the results of the decision, and fishermen can also judge based on the results whether the decision made by a real person is better than the behavioral decision made by the “digital twin.”

In addition, the digital twin AI of smart agriculture operates in the background around the clock, silently recording and analyzing the corresponding "behavioral decisions" of fishermen in response to various "facility factors" and "growth factors" in smart farms. Decision-making", slowly establishing the best solution model for the farming strategies. Slowly, AI silently learns these "tacit knowledge" from fishermen like a little apprentice at their side, so that this knowledge will not be lost when the fishermen retire.

Moreover, this technology can not only be used to "farm fish," but also "farm vegetables." These optimized farming models can become a precious database. Even novices who have just entered the industry can skip the process of exploration and directly become a master.

The greatest challenges currently faced are: insufficient manpower, aging population, loss of experience, and high cost of new technologies

Taiwan is famous for its agricultural technologies and farming technologies. However, small farmers generally have a shortage of manpower and aging workers. Digital transformation is imperative. The cost of new technologies is too high for 80% of small farmers and fishermen. Since there are too many uncertainties in environmental factors, such as climate change, and water quality changes, they are all highly dependent on experience. Therefore, the most severe challenge comes from farmers and fishermen retiring before young farmers and fishermen can take over, and many years of experience are lost because they cannot be passed on.

Smart agriculture and fisheries digital twin allow continuous optimization without downtime

"Digital twin" is an emerging technology that combines AI and HI craftsman wisdom, and was rated by Gartner as one of the top ten key technologies for the future for three consecutive years. The Department of Industrial Technology, Ministry of Economic Affairs began to engage in R&D of digital twin in 2016. It believes that in addition to automation efficiency, industries also need to digitally preserve experience and skills to develop optimal human-machine collaboration technologies through AI and HI interactive learning. In the field of aquaculture, the "digital twin" of AIoT (Artificial Internet of Things) for "fishery and electricity symbiosis fish farms" digitalizes the tacit knowledge of fishermen. Using the analysis of "facility factors" constructed from different types of water quality data and “growth factors” such as fish and shrimp images and disease symptom images, as well as the "behavioral decisions" of fishermen, to train AI can produce optimized models for water quality management, aquatic product growth management, and aquatic disease management. ▲The "digital twin" of AIoT for "fishery and electricity symbiosis fish farms" digitalizes the tacit knowledge of fishermen

▲The "digital twin" of AIoT for "fishery and electricity symbiosis fish farms" digitalizes the tacit knowledge of fishermen

These AI management models are combined to create a smart farming solution with high survival rate and high feed conversion rate. The entire farming process has digital monitoring data and quality that can be analyzed. Traceability can reach the initial stage of farming, greatly improving the quality, value, and output of aquatic products.

Despite promising prospects, there are still many challenges

The III IDEAS first become involved in “digital twin” due to a forward-looking technology project supported by the Department of Industrial Technology, Ministry of Economic Affairs in 2018. At that time, the Department of Industrial Technology believed that in addition to automation efficiency, industries also need to digitally preserve experience and skills to develop optimal human-machine collaboration technologies through AI and HI interactive learning.

Taiwan Agricultural Research Institute, Council of Agriculture, Executive Yuan subsequently supported the application of "digital twin" in smart agriculture. "The application of digital twin technology in agriculture helps small farmers digitally accumulate experience, and improves their agricultural skills through the interaction of group experience and AI, resolving the greatest challenge of intelligent agriculture.” Intelligent agriculture digital twin technology is expected to increase production efficiency by 30% after commercialization and is quite promising.

▲Digital Twin: Aqua-Solution

After working with technology-based aquaculture companies and gaining support from an industry project of the Industrial Development Bureau, Ministry of Economic Affairs, III IDEAS applied digital twin technology in the field of "smart fish farms." The field application team responsible for aquaculture pointed out: “In fish farms, fishermen often make different behavioral decisions when facing various environmental changes. The behavioral decisions made by experienced fishermen are three times better than ordinary fishermen in terms of results. For example, the survival rate of white shrimps is generally about 10%, but some fishermen can achieve a yield of up to 30%. This reduced production costs and tripled profits.

Digital twin technology can pass on the tacit knowledge of these experts and ultimately upgrade the entire industry."

The "digital twin" is composed of 9 sensors, fish images, and fishermen's behavioral decisions

9 sensors, constantly monitoring "facility factors" such as water quality

IDEAS uses nine sensors to monitor water quality, including dissolved oxygen, water temperature, pH, salinity, turbidity, ammonia nitrogen, nitrate, chlorophyll a, and ORP (Oxidation-Reduction Potential), in order to obtain the environmental data of various farms. These factors are also known as “facility factors.”

In addition, fishermen will regularly take fish and shrimp out of the pond, or use submersible cameras to take pictures of farmed species underwater. This is used to determine the current size of the farmed species and its growth condition, which is also called "growth factor."

▲"Facility factors," "growth factors" plus "behavioral decisions" made by fishermen in different situations can create a "digital twin" in the cloud server. (Source of diagram: Taiwan Salt Green Energy Co., Ltd. commissioned Sanyi Design Consultants Co., Ltd. to design)

With these two factors plus "behavioral decisions" made by fishermen in different situations, a "digital twin" can be created in the cloud server.

In this game-like "digital twin," we can simulate as much as we want to find the best "behavioral decision" under different "facility factors" and obtain the optimal "growth factor.”

To put it in a way that is easier to understand, readers can try to imagine that we have a game called "Happy Fish Farm." The environmental parameters of the fish farm are all recorded from actual situations. We also record the behavioral decisions made by each "Happy Fish Farm" player under different environmental parameters and the final results. When the number of recorded data sets is sufficient, a digital twin of the fish farm can be obtained from machine learning, and then real-time data is simulated to obtain optimal combinations. This simulated world is the "digital twin" of "Happy Fish Farm."

How is the issue of sensors easily being damaged resolved?

However, there will always be challenges in the R&D process. For example, underwater sensors such as water temperature and dissolved oxygen sensors are often damaged due to algae growth. Underwater cameras that record the size of fish are often blurred and unrecognizable due to sediment or algae pollution on the bottom of the pond.

There are two solutions for overcoming the issue with sensor damage. One is to regularly scoop water out from the pond and pass it through the sensor for detection. The other is to make the sensor into a box and put it into the pond every day to detect the water quality.

As for the growth condition of fish and shrimp, fishermen only need to fish them out of the pond every day to take pictures and measure them. Low cost and effective.

Team leader Chiu said: "We are currently developing a 9-in-1 water quality detection box. After successful integration, we can prepare for mass production and start commercial operation by selling the box plus a monthly connection fee."

Team leader Chiu of IDEAS of the III said: "The issue with sensor damage is the cost. Even though it provides great benefits, it would be meaningless if fishermen are not willing to use it due to high cost. We are currently developing a 9-in-1 water quality detection box. After successful integration, we can prepare for mass production and start commercial operation by selling the box plus a monthly connection fee. We are now very close to completing the integration, and welcome companies to discuss cooperation.”

Difficulties in recording fishermen’s behavioral decisions

Another challenge comes from fishermen. Some fishermen will consciously record the water quality and environmental indicators they observe every day, and record their own operating strategies and results. However, not every fisherman will do this. This is why it is necessary to use GAN (generative adversarial network) technology, which is very important in AI.

GAN will generate possible strategies of fishermen based on past data, i.e., it "guesses" the fishermen's decisions to supplement the behavioral decisions that the fishermen do not input. If it is completed by fishermen afterwards, it will not affect the training data set.

After the award-winning technology is put into mass production, 300% production efficiency will no longer be out of reach

Current applications of "digital twin" technology worldwide are mostly in aerospace and manufacturing. Taiwan and the Netherlands are the first to engage in the R&D of digital twin in intelligent agriculture. Therefore,the "Intelligent Agriculture Digital Twin" winning the U.S. R&D 100 Awards is proof of Taiwan’s technological leadership. We are currently completing the integrated water quality monitoring box and total solution, and the product is expected to increase production efficiency by 300%.

In the future, "digital twin" technology will not only be used in agriculture and fisheries, but can also be extended to industries that originally relied on "tacit knowledge", such as tea making, fisheries, etc. Due to the digitization of the entire process, quality no longer relies on experience and the weather. This can upgrade farmers' technology for "AI monitoring" and "precision production." In addition to improving the productivity of traditional agriculture and fisheries, it also has a good chance of achieving sustainable operations, upgrading the entire industry, and making it more appealing for young people to return to their hometowns to work in agriculture and fisheries.

Reference materials: A key piece of the puzzle of smart manufacturing! Innovative sensing technology that accelerates the realization of "digital twin" - Digital era