【2020 Application Example】 AI-Enhanced 'Banana Contract Cooperation Management System', Effectively Increasing Banana Export Value!

Banana industry faces low-priced impacts from abroad

In recent years, our country's banana industry has been impacted by low prices from the Philippines and Ecuador, with sales volumes decreasing annually, no longer seeing the golden era of Taiwan's banana exports to Japan.

The structure of banana pricing at the green stage doesn't vary much internationally, with similar inputs of fertilizers and harvested weights among countries. However, international banana pricing for a box from the Philippines is around 11 USD, whereas Taiwanese bananas cost around 22 USD per box. This is primarily due to the efficiency of investment capital and output at the 'collection centers' post-harvest. The fragmented and scattered local farmlands substantially increase the costs of final products and thus restrict the export dynamics.

Furthermore, climate change affects the traditional southern export regions for Taiwanese bananas. Warmer winters and altered summer rainfall patterns affect the physiognomies of the bananas produced, causing their size to rapidly exceed export standards and increasing the cost per unit of qualified goods during collection center processing; or excessive water content which depreciates the taste historically associated with them, leading to a decrease in market prices. These pressures from rising costs and dropping prices further squeeze the commercial value and viability of Taiwanese bananas.

Differences in planting environment affecting the stability of banana quality for export

A fruit and vegetable cooperative in Yunlin County, originally a domestic banana collection center located in Yunlin, wasn't historically a part of Taiwan's banana export regions. Since a field survey conducted in 2017 by TaiNong Co., Ltd., it was discovered that the quality of bananas produced in Yunlin has been comparatively stable against those from the southern regions. The tighter organization of local farmers and crop rotation practices between rice and banana farms helped reduce incidences of Yellow Leaf Disease and effectively maintain production levels.

▲ Banana export

However, without prior experience in exports, TaiNong gradually introduced Japanese standards for exporting with the local farmers, defining the size and width of fruit fingers, stalk cutting, and boxing methods. This aims to gradually establish a banana export hub in the central region. Yet, the climate in Yunlin significantly differs from the southern regions. Current practices in banana exporting are based on experiences from Kaohsiung and Pingtung and do not incorporate how the shift in production areas northwards affects banana growth. Hence, there remain excessive rejections at the collection centers occasionally causing disputes among farmers.

Agricultural risk management data service, development of banana specification volume fluctuation prediction model

台農發股份有限公司既有之集貨場對契作香蕉農戶包裝分類品檢機制,收集之數據資料與悠由數據應用股份有限公司配合,運用資料科學研究方法,透過研究規劃、資料蒐集擷取、資料清洗、特徵萃取、資料融合、資料分析演算法建立、分析結果、模板開發、專家會議討論等步驟建立分析應用流程。

By integrating dataset including collection centers' incoming batch container numbers, origin, banana quantities, data on each box of fruit bunches, and data of defect sampling records, along with internal purchase prices and prices from various purchasers, through the Banana Contract Cooperation Management System linked with data decision analysis systems and APIs, it supports subsequent judgments by providing analysis data to the fruit and vegetable production cooperative.

悠由數據擷取與蒐集香蕉契作戶產地之歷年氣象環境資料、公開批發市場的產地價格及香蕉生理模式等數據,結合台農發的分類品規數據,建立「香蕉品規量能波動預測」演算機制,並將分析預測結果回饋至香蕉契約合作作業管理機制。

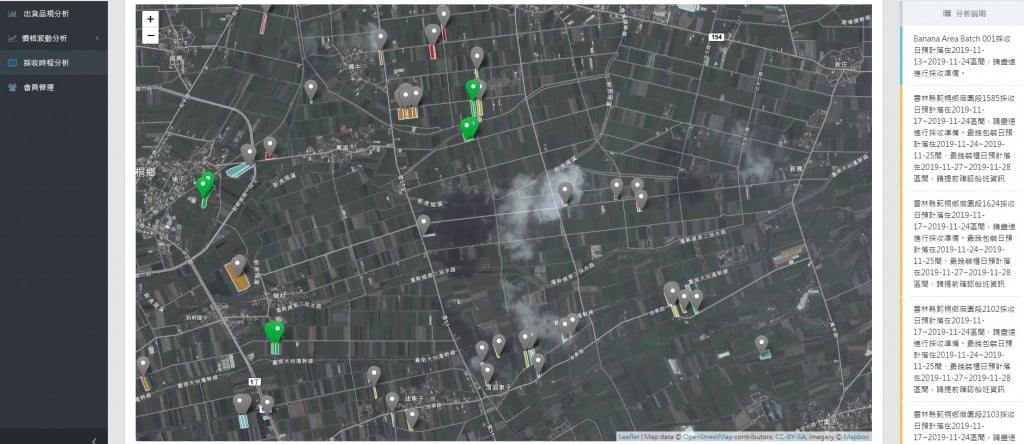

▲ Visualized harvest scheduling analysis

By leveraging varied predictive analytic outcomes of banana specifications, collection centers can utilize this as an advance warning and risk management decision-making tool, further adjusting supply to tackle inconsistent production capacity and specifications faced during acquisition.

Fruit and vegetable cooperative X TaiNong X Youyou Data Applications collaborating closely, creating a win-win-win!

This successful alliance formed a close cooperative relationship between the place of production, TaiNong, and Youyou Data. Previously, farmers often distrusted traders, and traders lacked control over farmers, leading to conflicts. This alliance allows the requirements of the distribution side to reflect actual shipment specification fluctuations and present them digitally, enabling farmers to objectively understand their shipping quality and empathize with the difficulties of traders, thus fostering cooperation.

Innovative model of banana contract management

TaiNong's cooperation with Youyou Data on the banana contract management system provides a platform that combines crop physiology with climate predictions to obtain foresight data. For other products managed by TaiNong, such as pineapples, lettuce, carrots, and pineapple sugar apples, this has been greatly enlightening.

In the future, by facilitating farmers to participate in the Production History System and connecting land registry data with this contract system, the introduction of the Production History System will be aided. This system is also considered by TaiNong for commercial acquisition moving forward.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」