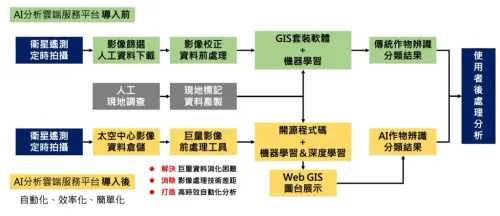

【2020 Application Example】 The Lawsnote compliance system uses AI technology to automate the compliance risk assessment (CRA) process and improve the compliance efficiency of companies

Trends in financial regulation

As the world pays greater attention to regulatory supervision, various fields are facing increasing compliance costs. If we were to ask what was the fastest growing field in 2020? I believe many people will think it is regulation!

The trend of strict supervision has been the most severe in the financial industry. Supervisory agencies In Taiwan, including the Financial Supervisory Commission, have imposed growingly strict supervision requirements on the financial industry, as well as heavier fines. In response to these supervisory measures, the financial industry gradually implemented new internal control and internal audit systems for compliance a few years ago, such as the assessment of regulatory risks, business units appointing compliance managers as the first line of defense, and compliance self-assessment system.

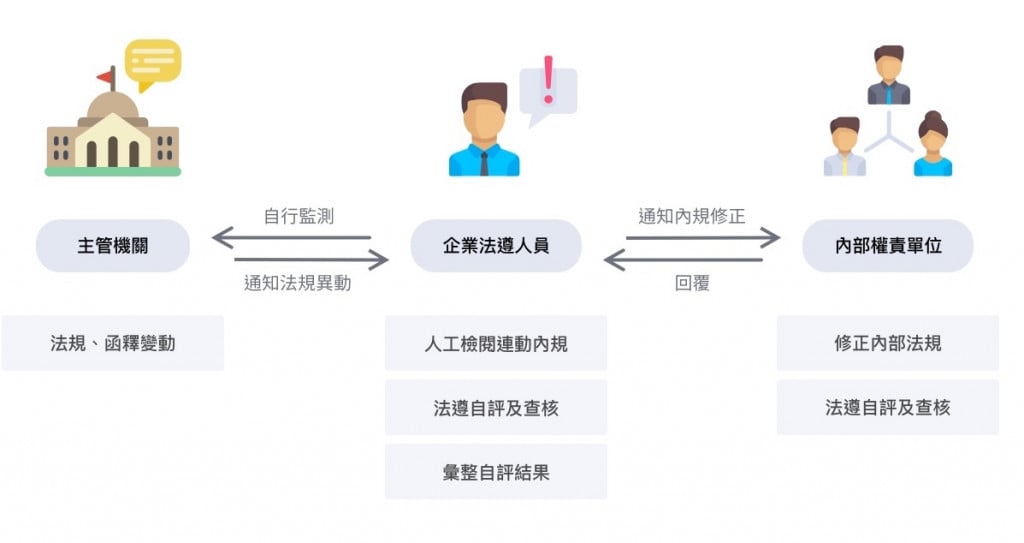

Current manual compliance process of compliance personnel

However, there is a plethora of financial-related laws and regulations, and business units have a large number of complex business manuals. Therefore, many compliance personnel of financial institutions must spend a lot of time on tedious and highly repetitive comparisons of internal and external regulations, in order to help companies avoid risks or fines due to not proposing response measures in their internal regulations when laws are amended.

▲Compliance personnel spend a lot of time dealing with regulatory changes

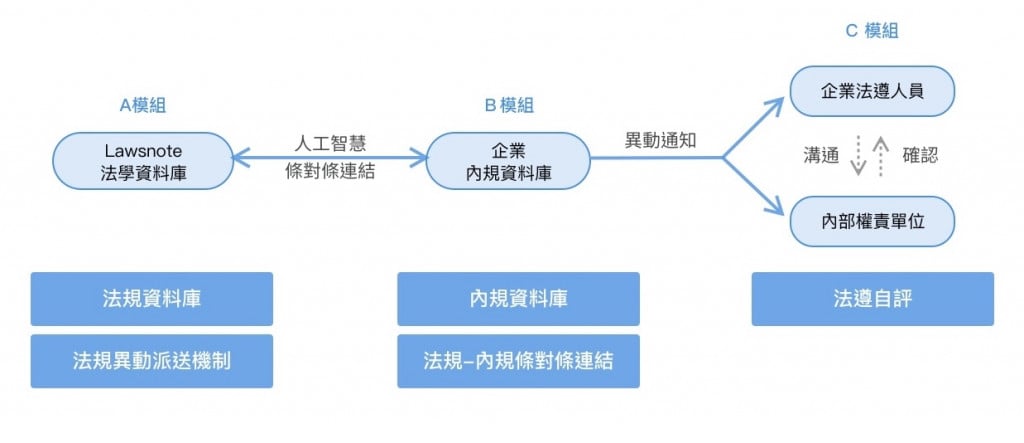

Lawsnote Compliance System Solution

As Taiwan's leading legal technology solutions provider, Lawsnote received many requests from corporate customers for a compliance system, and began to look into solutions for applying AI to compliance systems. It thus developed the Lawsnote RegTech compliance system for compliance personnel to automate parts of their work process, reducing the tedious and repetitive work of compliance personnel.

▲Lawsnote automates regulatory changes and internal regulatory adjustments

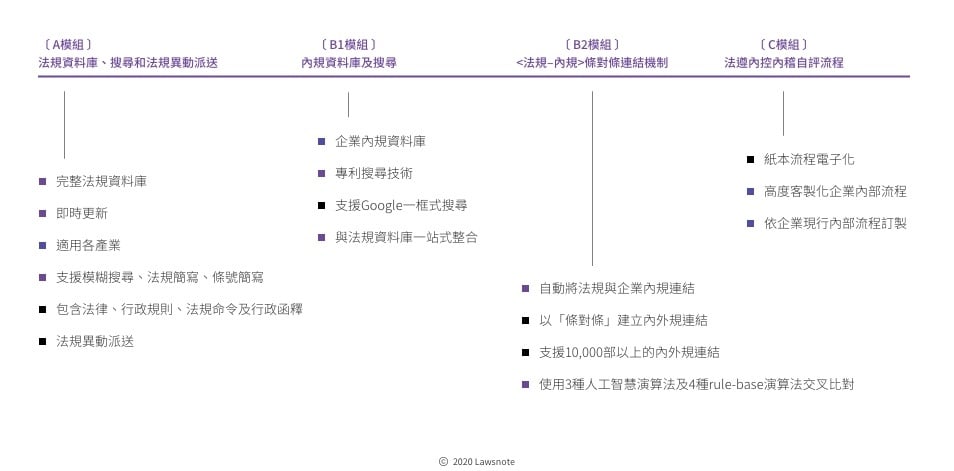

A Regulatory database, search, and notification of regulatory changes

As the basis of the RegTech system, the compliance process is triggered by "regulations", so it is necessary to have a "complete" and "real-time" regulatory database and regulatory update mechanism for specific fields.

However, regulations are not limited to "laws" enacted by the Legislative Yuan, but also include "administrative rules" and "legal orders" enacted by administrative agencies authorized by law, as well as "administrative interpretations" used to interpret regulations. These are all considered regulations that the compliance system must comply with.

There is currently no unified data source for these regulatory data. Except for the Laws & Regulations Database of the Republic of China (Taiwan), many regulations are scattered on independent webpages for regulations on the websites of different agencies, organizations, or associations, making the cost of collecting complete regulations very high.

Since laws and regulations will be amended, new administrative letters and interpretations will be issued or old ones abolished, updating regulatory changes is also a big problem. Even if complete laws and regulations are collected once, failure to continuously monitor changes in laws, regulations, and administrative letters and interpretations will also create a gap in compliance.

As a professional legal search engine, Lawsnote has a complete database of regulations and interpretations, and can send notices of regulatory changes required by various fields in response to the needs of compliance systems.

B1. Internal regulations database and search

Internal management by companies through regulations are called "internal regulations." General types of internal regulations include company internal regulations, standard operating procedures (SOPs), and business instruction manuals. Depending on the intensity of industry-specific supervision, the number and density of company internal regulations will vary depending on the industry.

In industries with high supervisory density, the number of internal regulations sometimes reaches thousands or even tens of thousands. With such a huge number of internal regulations, paper or simple filing systems can no longer meet the internal needs of enterprises. The process of searching for and complying with internal regulations might require a significant amount of time and personnel costs if an internal regulations database and search engine are not establish.

Lawsnote has Taiwan's most powerful legal information search engine, patent search technology, and uses AI to optimize its sorting algorithm. It can establish an "internal regulations database"for internal data, such as company internal regulations, SOPs, and instruction manuals, and applies search engine technology to the internal regulations database, achieving a fast, complete, and easy-to-use internal regulations database and search engine.

B2. <Regulations – Internal Regulations> Article-to-Article Linking Mechanism

When regulations are revised, the company's internal regulations must also be inspected and adjusted accordingly.

The company's internal regulation inspection procedures may be initiated by compliance personnel based on regulatory amendments, or may be initiated by the compliance officer of the business unit (the first line of defense), and then reviewed by compliance personnel (the second line of defense). However, regardless of which unit initiates it, the difficulty lies in finding the article of internal regulations that correspond to the amended article of the law to determine whether amendments are necessary.

Due to the large number of internal regulations, complicated terms, and the different forms of business involved, if internal regulations must be reviewed every time laws and regulations are revised, it will consume a huge amount of time. Therefore, compliance personnel usually rely heavily on experience and aim to minimize risk within limited time.

Moreover, due to the way internal regulations are written, often using different methods to significantly rewrite and break down laws and regulations, making comparison very difficult for programs. If the existing program is used to compare internal and external regulations, many internal regulations cannot be effectively determined.

After research and testing, Lawsnote designed 3 AI algorithms and 4 rule-base algorithms for cross-comparison, which can establish article-to-article links between thousands of regulations and company internal regulations, helping compliance personnel to immediately determine the necessity of revisions to internal regulations when regulations are revised, significantly saving review time and reducing compliance and internal control risks.

C. Internal control and internal audit self-assessment process for compliance

In order to ensure that the compliance officer of business units properly carry out the compliance process, some companies will implement mechanisms such as compliance self-assessment and compliance education, and require the compliance officer of business units to conduct self-assessment of internal control and internal audit processes and review existing risks.

Compliance personnel or auditors must summarize self-assessment results, or prepare a risk matrix to monitor compliance risks and track vulnerabilities.

The Lawsnote RegTech compliance system supports expanded workflow solutions, which can extend the workflow to the compliance self-assessment process, customize the integration of the current system and compliance system, and merge the organizational structure and SSO permission control mechanism to create a one-stop compliance system.

▲Three core modules of the Lawsnote compliance system

Incorporates foreign regulations and is the number one compliance tool for companies

Lawsnote will continue to optimize regulatory text parsing and identification technology. In addition, we will also develop other legal technology application tools and become the number one compliance tool for enterprises with all-inclusive services. In addition to domestic regulations, Lawsnote will also incorporate foreign regulations into the system, so that multinational companies in Taiwan can access information on domestic and foreign regulations.

Lawsnote has always focused on AI applications, data mining, algorithm design, search engines, and workflow optimization in the legal field, and is committed to saving the time of legal professionals through technology.