【2021 Application Example】 Watsons Introduces Insider AI Technology Platform to Strengthen Customer Experience and Enhance Conversion Rates

Watsons Taiwan, holding the leading position in physical chain drugstores in Taiwan, has continued to expand its digital transformation. Since establishing Watsons' online store in 2014, apart from actively developing the e-commerce market, the company has significantly enhanced the online and offline (O+O) omni-channel consumer experience by integrating Insider AI technology. This integration utilizes extensive in-store sales data, consumer behavior analytics, and AI-driven personalized recommendations delivered at optimal times to increase conversion rates.

O+O Online Plus Offline Boosts Customer Conversion Rate, Driving Business Growth

Watsons Group, a global retail giant, has been deeply rooted in Taiwan for the past 30 years specializing in retail, store operation SOPs, and retail supply chain optimizations. However, managing an e-commerce platform only began a few years ago. Unlike the commonly discussed 'O2O' (online to offline) in retail, Watsons adopts 'O+O', which is offline plus online. Currently, about 20% of customers who order at Watsons' online store choose to pick up their goods at physical stores. Proper service at these stores acts as a catalyst for converting online-originated customers into additional in-store revenues.

According to statistics, Watsons has nearly 6 million members with a substantial volume of transactions in physical retail outlets. However, with over 1.2 million active app users and nearly 3 million app downloads, the level of member activation is still lacking. By utilizing AI technology for data integration, such as providing optimized product recommendations through AI, Watsons could significantly enhance its customer conversion rate from offline to online consumption or guide online customers to in-store purchases, thereby driving business growth.

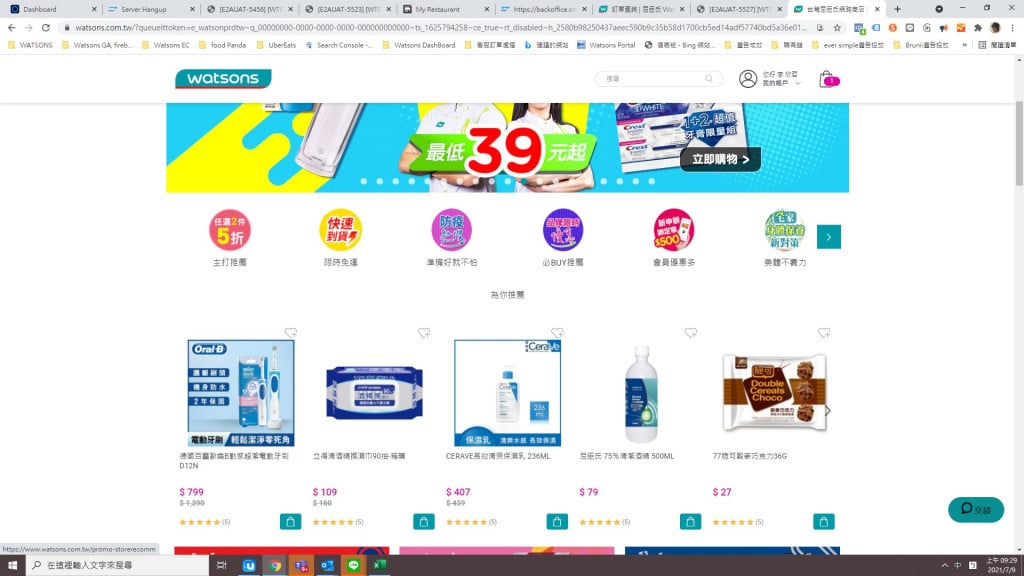

▲ Homepage Personalized Recommendation Module: Recommended for You

Originally, Watsons used the e-commerce solution Hybris from the global system integrator SAP, which was more geared towards simple display and sales, lacking sufficient technical resources to handle enhancing the consumer experience.

Insider is a marketing technology (martech) company with offices in 25 cities globally, including a professional consultancy team in Taiwan that provides localized digital solutions. Committed to optimizing digital marketing effectiveness with technology, Insider helps brands drive digital growth and is a partner to many domestic and global enterprises including Watsons, Carrefour, IKEA, Lenovo, Adidas, Sinyi Realty, and Singapore Airlines. Insider has shown outstanding performance in improving customer conversion rates, repurchase rates, and advertising ROI through AI technology.

Watsons introduced Insider's AI algorithms primarily for enhancing customer experience, using AI's personalized and integrated marketing modules to elevate the customer interaction and improve e-commerce conversion rates. Additionally, AI functionalities search for the right customers, expanding new customer groups and providing a superior shopping experience.

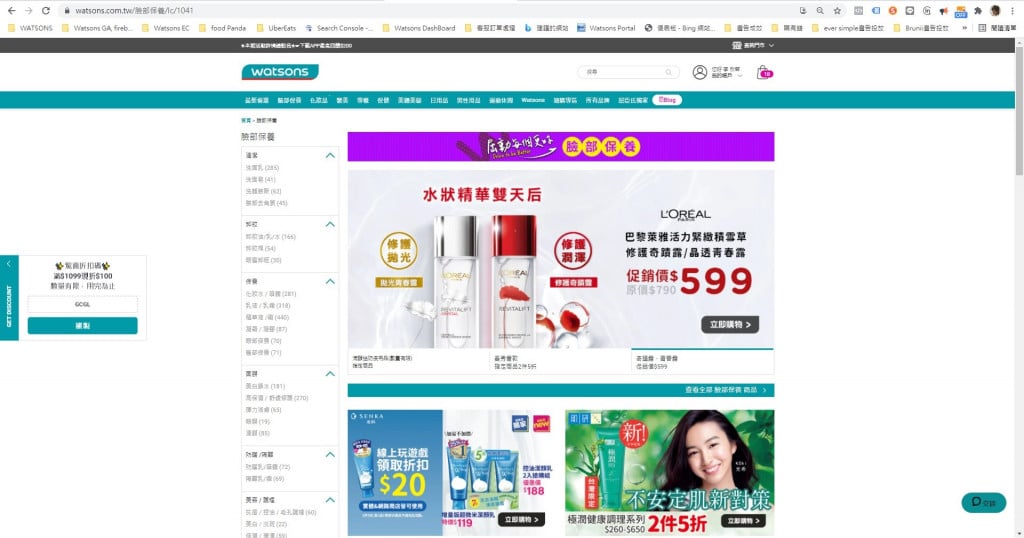

▲ Page-specific Discount Code Copy Feature Recommended Based on Customer Behavior

Insider has developed various technological modules that can be applied in different customer scenarios to enhance conversion rates. Currently, Watsons' e-commerce website/APP utilizes different Insider modules, with some parts also tailored based on Watsons' unique attributes such as necessities repurchase, app navigation, and scratch card discounts, designing conversion kits or personalized recommendation modules for specific customer situations within Watsons.

Introduction of Web/APP Personalized Recommendation and Conversion Module Kits Effectively Increases Conversion Rates by 10%

Watsons has already introduced the first four of the planned modules, with a full rollout of all five modules expected by 2021, aiming to enhance both online and offline cross-sales and thereby comprehensively improve Watsons’ overall e-commerce and retail performance. 1. Web Recommendation/Conversion Suit 2. App Recommendation/Conversion Suit 3. InStory for eCommerce 4. Mobile App Template Store 5. Insider Architect

▲ Watsons has currently implemented the AT module, with completion expected by the end of 2021.

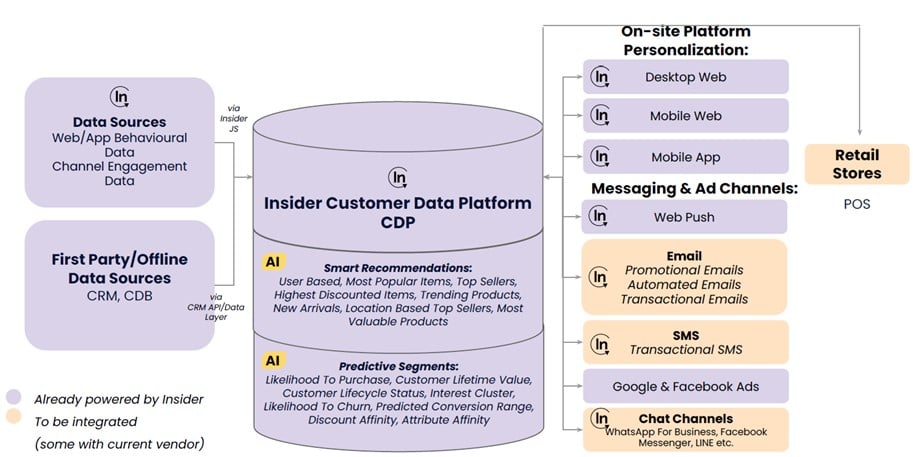

Since partnering with Insider in 2020, Watsons has introduced Web/APP personalized recommendation and conversion module kits, effectively increasing transaction conversion rates by an average of over 10%, with ROAS (Return on Ad Spend) averaging over 10. Watsons also hopes to integrate POS sales records into Insider's CDP (Customer Data Platform) to achieve a more optimized O+O interaction mechanism and complete an all-channel consumer experience.

By combining Insider's AI technology, Watsons' self-operated official website, supplemented by extensive in-store sales data and member consumer behaviors, along with AI's personalized recommendations delivered at optimal points, the technology will significantly boost consumer transactions online and interactive opportunities in-store. Utilizing new technologies in the competitive e-commerce sector allows Watsons to maintain a unique leadership position in the beauty/health category in the consumers' minds.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」