【2021 Application Example】 Eastern Home Shopping Implements OneID AI Traffic Monetization Service, Cost-Effectiveness Up to 2 Times

How to integrate consumer data from various group companies to create advertising synergy and enhance the conversion rate of e-commerce guided orders is probably what every cross-industry business owner dreams of. No problem, this can be achieved gradually through AI!

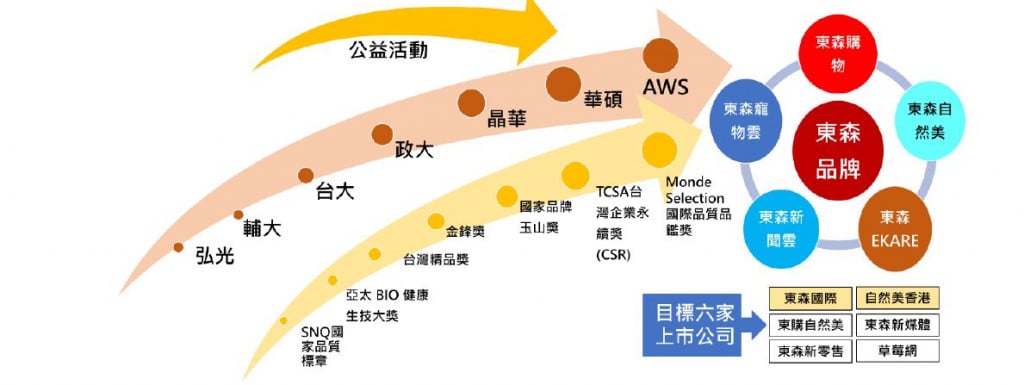

Eastern Home Shopping is affiliated with the Eastern International Group, which includes East International, Eastern News Cloud, Eastern Insurance Representatives, Eastern Natural Beauty, Eastern Global Marketing, Eastern Pet Cloud, HerEastern, Focus Media, Hong Kong Strawberry Net, and Bear Mom's Vegetable Market, among other companies. With cross-industry and cross-domain relationships within the group, and independent operations of membership systems in each unit, consumer data could not be exchanged within the group, making it difficult to uphold Eastern Group's promise to 'place customers in a godly position'.

▲ Eastern Group’s companies cover a wide range of industries, with large and scattered member databases.

The Eastern Group boasts significant member traffic and has applied AI news recommendation algorithms and other related technologies across various venues. However, the independence of member systems in each unit of the Eastern Group prevents the exchange of consumer data within the group, lacking a comprehensive basis for consumer behavior analysis. This results in the inability to enhance the precision of personalized services and marketing strategies.

When analyzing the challenges and trends of the current retail market, Eastern Group remarked that in response to changing consumer demands, non-traditional business models are emerging, leading to the fragmentation of retail. Various emerging business models provide services or products catering to their niche markets, leading consumers to rely less on traditional retail models.

Retail fragmentation, becoming more apparent in emerging countries, rapidly develops new forms of retail such as high-growth flash sale eCommerce, which threatens traditional B2B2C eCommerce platforms. These emerging business models quickly divide traditional retail spaces and could revolutionize existing market rules. The retail market is expected to continue evolving towards segmentation.

The rapid integration of AI applications in the new retail industry to meet highly competitive markets

Under the trend of merging physical and digital realms, the line between offline retailers and online e-commerce is increasingly blurred. Offline retailers are setting up brand official websites and developing brand apps, investing in e-commerce platforms, while e-commerce operators are starting to established offline physical experience stores, enhancing touchpoints with customers. Both are exploring consumer data profiles through offline-online integration, based on AI technologies like machine learning, deep learning, computer vision, language processing, mobility control, and decision-making technologies to actively integrate intelligent retail AI applications, shaping the new retail industry.

Additionally, Google Chrome claimed in 2021 that it would disable 3rd party cookie functionality within two years, causing retail companies to lose the ability to track personalization via Cookies and understand user behavior across different times, locations, and ads. This will prevent cross-device, cross-platform tracking, forcing companies to transform and face big challenges in traffic advertising sales.

Therefore, the Eastern Group decided to implement the 'OneID AI Traffic Monetization Service Validation Plan', establishing an exclusive data alliance for the Eastern Group, using 'Unified ID' for cross-industry, cross-service data exchange. Transforming from collecting personalized data of related companies to analyzing common behavioral characteristics of consumers across industries, segmenting them to obtain users with similar behaviors, and providing interesting content. Additionally, utilizing first-party data and AI technologies to improve ad click-through rates, enhancing the advertising value and e-commerce guided order conversion rates.

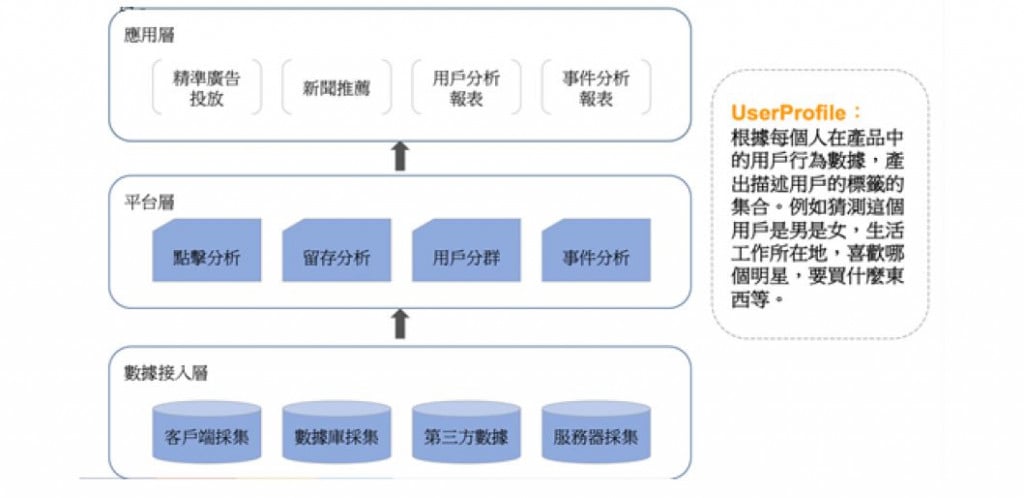

This AI technology project is co-developed by Eastern and ASUS computers, encompassing major development tasks such as project planning, system architecture design, system environment setup, algorithm development, algorithm model validation, and system verification. The employed technologies include a big data parallel processing framework, natural language processing, user recommendation embedding systems, similarity search, search engine indexing, and click rate prediction. This project aims to develop a comprehensive data collection, processing, and integration platform 'Data Middleware', collecting various data sources, focusing on users as the basic unit, forming structured data tables, and calculating user tags for precise characterization of each user. Subsequently, this data is utilized for precise AI advertisement placements.

▲Eastern Data Middleware structure diagram

Eastern Home Shopping introduces OneID AI Traffic Monetization Service, predicting cost-effectiveness to be up to 2 times

Eastern stated that this project primarily applies 'user behavior data' and 'AI technology', with user behavior data provided by the Eastern Group and AI technology being co-developed by company and ASUS teams, covering systems such as AD Serve, precise audience estimation system, AI automatic optimization system, advertising efficacy system, and user profiling system. The customer data and traffic of AI technology co-developed with ASUS remain independent and not interconnected.

According to estimates, this development project's total cost-effectiveness could reach 200%, expected to precisely capture the user's digital trajectories, behavior, and profiles, potentially resulting in significant growth in customer lifetime value (LTV), effectively integrating Eastern's online and offline services, enhancing membership service content, and substantially increasing corporate value.

In the future, as the Eastern Group continues to expand into international markets, it currently targets Mainland China as the primary promotion market, extending the entire service module with Eastern Global’s operational model to the global Chinese market while ensuring compliance with GDPA, merging it with Strawberry Net to provide Eastern's new retail services with the advantages of big data and AI globally.

▲Eastern Group will expand its services and technology to the global market through Strawberry Net.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」