【2020 Solutions】 Wise Stability Tech becomes the third eye for companies through image recognition

AI automated optical inspection (AI-AOI) and Artificial Intelligence of Things (AIoT) are used for deep learning model training, achieving AI predictions and pushing factories towards automation. Recognized as 'experts in intelligence image analysis technology', Wise Stability Tech becomes the third eye for companies through image recognition.

In recent years, Artificial Intelligence (AI) has been widely applied across various sectors including finance, retail, transportation, manufacturing, and automation industries, forming the core of 5G, IoT, and industrial development. Advanced countries are racing to invest significant resources in the development of AI technology.

Founded in 2016, Wise Stability Tech focuses on image recognition solutions for smart factories, particularly emphasizing the application of AOI (Automated Optical Inspection). The team possesses capabilities in electromechanical integration, excelling in image recognition applications such as product inspection, attendance, and facial recognition, establishing a complete AI positive feedback loop with clients.

Wise Stability tech becomes the 'third eye' for companies through image recognition. The specific approach begins first with data evaluation and consultation; secondly, data organization and labeling; thirdly, AI algorithm selection, verification, and AI training services. These three steps provide companies with a comprehensive hardware and software integration solution, grounding the latest AI technology for practical use and solving enterprise challenges effectively.

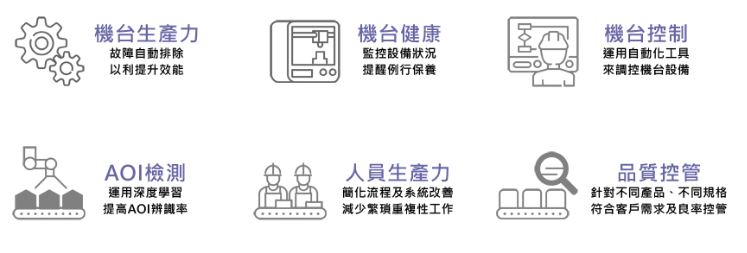

▲Wise Stability Technology Service Model

Using an API integration approach to implement AOI testing significantly reduces defect rates

Wise Stability Tech uses high-precision AOI optical image inspection systems and installs industrial cameras. By adopting deep learning methods, various fabric defects are automatically categorized, significantly reducing defect rates. The introduction of AI technology is facilitated through API integration, providing AOI inspection services with a total quality control standard up to LFW99.8%.

Wise Stability Tech currently focuses on fabric defect inspection. Traditionally, textile inspections were done only by the human eye, a method that could reduce yield rates under long-term workload. Replacing visual checks with AI recognition and integrating it into the production line quality control and service environment maintains high-efficiency defect inspection. As it is non-manual operation, it avoids fatigue, not only upgrading the recognition rate but also shortening the inspection processing time, thus stabilizing and enhancing quality control. Additionally, it enables a better understanding of other factors affecting quality through inspection processes, achieving production improvements and standardization goals.

However, during the implementation process, some clients have high expectations for AI, believing that just by introducing AI, it can replace existing manpower and solve all problems on the production line. But in reality, the value of AI lies in accumulating a large amount of high-quality data, which is then converted and analyzed to build AI training and verification models. Only through processes like machine learning and deep learning can the problems caused by manual operations be completely resolved and operational procedures optimized.

Therefore, the AI image recognition technology and deep learning algorithms developed and trained by Wise Stability Tech have incorporated intelligent image analysis technology into the manufacturing chain. In addition to the already implemented fabric defect detection, these technologies can also be applied to workplace safety event recognition, defect inspection systems, and various customized recognition services, providing a diverse application environment.

「Translated content is generated by ChatGPT and is for reference only. Translation date:2024-05-19」